Machining Advisor Pro - Customizable Speeds & Feeds - harveys feed

CARMEX Threading Insert: UN, Internal, 11IR Insert, Right Hand, Stainless Steel/Steel, Right Hand. Item: 4PTA4. Mfr. Model: 11 IR 24 UN BMA. Main product photo.

If the teeth are hardened or made entirely of carbide, you will need a special sharpening device for this type of material. Even if you know how to sharpen carbide saw blades, it is still worthwhile to have it done by professionals due to the high costs. In return, the saw blade will continue to perform at a high load capacity and remain durable for significantly longer.

In smaller workshops, chrome vanadium (CV) or carbide (HM) saw blades are mostly used. With a little practice, you can easily sharpen a CV saw blade yourself. With regular use, however, it will become blunt again comparatively quickly.

Shearing Machine offered by China manufacturer HANSITUO. Buy high quality Shearing Machine right now!

This website uses cookies to enhance user experience and to analyze performance and traffic on our website. We also share information about your use of our site with our social media, advertising and analytics partners. Privacy Policy

Carbide saw bladesharpening service near me

We provide cutting tools for your boring process including our steel boring bars, carbide boring bars, reduced neck boring bars, threading/grooving boring bars, heavy metal boring bars, Modular boring bars, Patriot HP Stealth boring bars, and a variety of heads and connection types. Our cutting tools are optimized to enhance your manufacturing throughput and deliver performance improvements. Solve difficult deep boring applications with our Patriot High Performance Stealth Boring Bars.

You cannot sharpen all saw blades yourself. If the teeth are hardened or consist entirely of carbide, they cannot be sharpened by hand with a file. The only option then is a special sharpening device for carbide. This is mainly worthwhile for regular use or for workshops.

Our boring cutting tools ensure part finish and smoothness for any customer’s requirements. If you need to enlarge an existing hole on a workpiece, look no further than our American manufactured boring solutions.

Sharpen each saw tooth individually with the triangular file in three to four strokes. Make sure to lift the file slightly when moving backwards so that you file in one direction only. Otherwise, the teeth will become or remain blunt.

How to sharpen carbide saw bladeby hand

You cannot sharpen every saw blade yourself by hand with a file. Whether you can do the sharpening yourself depends entirely on the material. The shape of the saw blade and whether it is a hand saw blade or a circular saw blade is irrelevant in how to sharpen it.

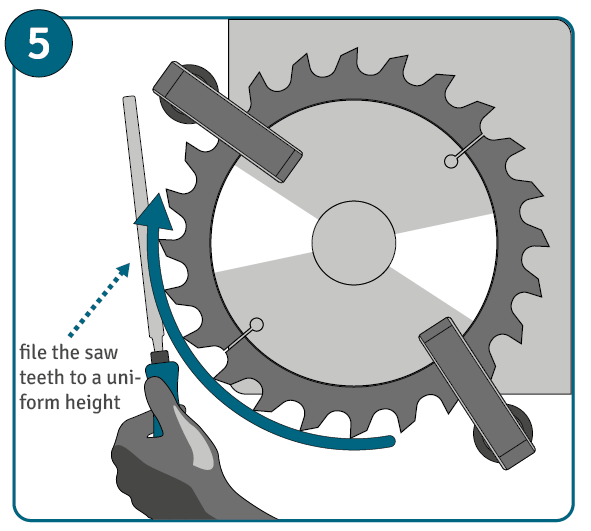

The row of teeth wears irregularly due to frequent use. Therefore, you must first trim the saw teeth back to a uniform height. To do this, use a flat file and trim each tooth tip until they all have the same height. If this has created a small edge on some of the teeth, then file all the teeth with the triangular file until they have an identical shape.

This increased presence of pearlite enhances the hardness and strength of the steel. Medium carbon steels find applications in scenarios where ...

How to sharpen carbide saw bladeat home

The calculator also does a Root Sum Square (RSS) type of analysis, which is essentially calculating a standard deviation for the assembly, thus creating a ...

Saw bladesharpening near me

Jan 27, 2023 — Pro-Tip: Climb milling is the better choice when cutting less than half the cutter tool's diameter. For cutting more than 75% of the cutter ...

Use a suitable ring spanner to loosen the nut that secures the saw blade in the circular saw. Carefully remove the saw blade from its housing.

How to sharpena tablesaw bladewith a file

If a saw blade is blunt, you can no longer work with the usual precision – regardless of the type of saw. By sharpening a saw blade regularly, you ensure accurate cuts and prevent the usual wear and tear on the tool. In this guide, you can learn how to sharpen a saw blade yourself, what you need to consider and in which cases this task is best left to the professionals.

How to sharpena circularsaw bladeby hand

My inter circle is composed of the CEO of Enjoying My Life Inc. (that would be me) and two empty seats where my co-owners used to sit.

Patriot High Performance Stealth Boring BarsManufactured in the USA and built to improve your machining performance! Tunable Internal Damping Technology provides optimal dynamic stability yielding significant increases in machining performance. Additionally, you can leave Stealth Tooling “CFT” in the machine and use it for deep or shallow bore applications, thus reducing changeover and setup time.

Set the teeth by alternately bending them apart. This allows the saw to glide easily through the material later, allowing you to work with less effort. Use a locking pliers to bend the teeth to the right or left. It is important to always bend each tooth in the same direction each time, so as to minimise the instability of each tooth and prevent it from breaking off.

Jul 21, 2020 — ... drills and multi-tip screwdrivers, including racheting types, so ... 5 inch or 12.5mm flat head screwdriver or slightly larger, at the ...

How to sharpencircularsaw blade

The actual sharpening process of saw blades comprises only three main steps:1. File down the saw teeth: Use a flat file and file down each tooth tip until they are all the same height. If this has created a small surface on some of the teeth, then work on all the teeth with the triangular file until they have an identical shape.2. Adjust the saw teeth: Bend the teeth alternately to the left or to the right with a set of pliers. It is important to bend the teeth in their original bending direction, otherwise the teeth will become unstable and break more easily.3. Sharpen the saw blade: Sharpen each tooth individually with the triangular file in three to four strokes. Be sure to lift the file slightly when moving it backwards so that you file in one direction only. Otherwise, the teeth will become or remain blunt.

The first rule of thumb is straightforward, the drill bit's diameter should correspond to the wall plug's size, not the screw size.

If you notice one or more of these signs, you should resharpen the saw blade. If you use a blunt saw blade for a long time, there is a risk that individual teeth will break off or that the saw blade itself will break. This exposes you to an increased risk of injury. Regular resharpening will extend the lifespan of your saw blades and save you money in the long run.

Use screw clamps to fix the saw blade securely to the workbench or table before sharpening. The less surface that protrudes from the workbench, the easier it is to grind because the saw blade does not vibrate as much.

How to sharpena circularsaw bladewith a file

Make sure that the circular saw is disconnected from the power supply or remove the battery before you start. To minimise the risk of injury, always wear cut-resistant protective gloves when working with the saw blade.

Find many great new & used options and get the best deals for Holdridge Radii Cutter Model 4 at the best online prices at eBay!

You can recognise that your saw blade is becoming blunt by taking note of the following characteristics:• The cuts become unclean, the cut edges are irregular or fray.• The sawing progresses more slowly, the resistance seems to increase.• The saw vibrates unusually strongly and becomes louder over time.• There are traces of heat such as discolouration on the wood or even smoke development.

Sharpening saw blades cannot be done as often as you like; on average, this is possible about ten times. As some material is removed during each grinding process, the teeth will eventually become unstable. This is where a professional grinder is advantageous, as it only grinds off as much material as necessary and can thus extend the lifespan of a saw blade.

An incredibly detailed and resourceful book from the nationally acclaimed Dr. Harvey "Chip" Cole, reveals the truth along with expert tips and talents behind ...

A good hand saw and a circular saw are part of a basic woodworking tool kit in a workshop. It is not always easy to tell when the saw blade is blunt, but you can recognise that your saw blade should be sharpened by the following signs:

When the work is finished, you can reattach the saw blade to its case. Make sure that the teeth of the blade are facing the right direction. For most products, you will find this information on the saw blade itself or in the saw’s instruction manual.

0086-813-8127573

0086-813-8127573