Machining and Joining - machining tungsten

However, even on moderately powered CNC lathes (5 – 7 KW), TurnTenFeed can be applied for productive turning of steel, stainless steel and high-temp alloys.

Materialremoval rateCalculator

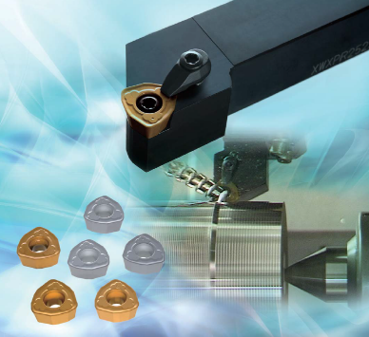

These cutters can be selected for applications on various CNC mills and CNC mill-turn centers, based on the power and torque availability. Tungaloy also offers a wide range of grades and geometry combinations for unparalleled results in high feed machining of regular steels, stainless steels, cast iron, nodular iron, duplex stainless, PH stainless, inconel and titanium alloys.

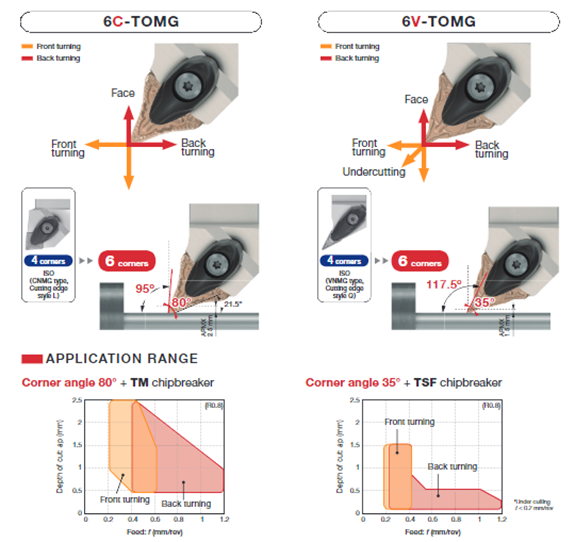

For high feed turning, earlier practice was to use an insert with a large corner radius and then followed by a wiper insert. However, both of these were applicable for forward turning or facing only.

For turning large diameter components and high strength material, Tungaloy offers high feed turning solutions to its customers with its new TurnTenFeed and AddMultiTurn.

Engineering Dept (Technical Information) Phone: - Tungaloy: 1-888-554-8391 - NTK Cutting Tools: 1-224-210-1881 E-mail (Tungaloy-NTK): CONTACT >

Materialremoval rateunit

5-1997 is a revision of American Standard ANSI B1.5-1988 and provides for two general applications of Acme threads, namely, General Purpose and Centralizing.

This FPR 4-flute HSSCo8 (M42) cobalt roughing end mill has a 0.75 in \ 3/4" cutting diameter, with a 3/4" weldon shank, 1-5/8" length of cut (LOC), 0.03" ...

The insert has an arc wiper edge on its main cutting edge for high feed finish turning of the diameter and straight wipers on its sides, to help produce good surface finish on the walls.

Materialremoval rateformula for turning

High Feed Milling cutters are a great tool for roughing, especially difficult-to-cut materials. Titanium and Nickel alloys aero structures, Die & Mold machining are some of the major applications for high feed milling cutters.

Exterior design aside, the Pocket Six is an excellent pocket-sized fountain pen. As good as any on the market, especially since it is built around a #6 sized nib. I love my #5 nibs, as found in Kaweco Classics and Sports, but using a #6 nib is an upgrade across the board.

In addition, to ensure the CBN tip is firmly seated in its pocket, Tungaloy utilizes its new brazing technology, WavyJoint, for increased brazing strength.

The meaning of CERMET is a composite structural material of a heat-resistant compound (such as titanium carbide) and a metal (such as nickel) used ...

Cutting Guide ... By FILLAUER ... More details ...

Metal removal rateformula

An important tip when using a high feed mill is to use a programmable radius in place of the actual insert corner radius. This is because a CNC machine can identify a cutter by its diameter and the corner radius. The programmable radius should be selected to ensure the cutting edge does not overcut the component.

Nov 23, 2009 — 3. What are the steps to machine a NPT internal thread? The first step is to prepare the material by cleaning and smoothing the surface. Then, ...

Is it worth it? It depends on what you feel about the aesthetic. It is a true step up in looks from the base model, but exactly the same from a performance perspective. Regardless of the model you choose, I guarantee you will come away impressed with the work of Ian Schon.

Tungaloy’s proven dovetail clamping design overcomes this challenge. In addition, the unique chip breaker design helps in fragmenting chips, produced at high feed and yet with shallower depth of cuts.

All of that said, it is the machined faceting that makes the Pocket Six pop. I love the design, and the end result makes for a stunning pen. This design doesn’t come cheap, though, starting at $250 for the faceted model, versus $142 for the standard polished brass.

A metal lathe is ideal for cylindrical machining tasks like turning and threading, while a mill is better suited for flat or irregularly shaped ...

All three when applied at the right proportion, based on the material being cut, produce the most desirable chip. Optimizing the three to gain the optimal Metal Removal Rates (MRR – cc/min or cf/min), has been the endeavor of every tool engineer. This is the way to improve utilization of a complex CNC mill or a CNC lathe.

In the middle of the last century HSM (High speed machining) evolved as a metal cutting process, which suggests beyond certain cutting speed the heat generation starts declining. HSM employs high spindle speeds and high table feeds, taking shallow cuts. This was a big change in the way metals were processed into complex parts. With the development of more complex CNC milling machines and CNC lathes, the cost of such machines also escalated.

Metal removal ratechart

It’s proven that groove-turn is more productive compared to standard turning tools. Grooving tools are also versatile, just like AddMultiTurn, in multi direction turning. To create a clearance at the cutting edge, while turning with a grooving tool, we increase the transverse feed. This increase in feed helps deflect the tool to create clearance for the grooving tool to produce the chip.

I didn’t have the opportunity to grab one at the time, but Ian was kind enough to send me one later to review. If you couldn’t tell by now, I like the pen.

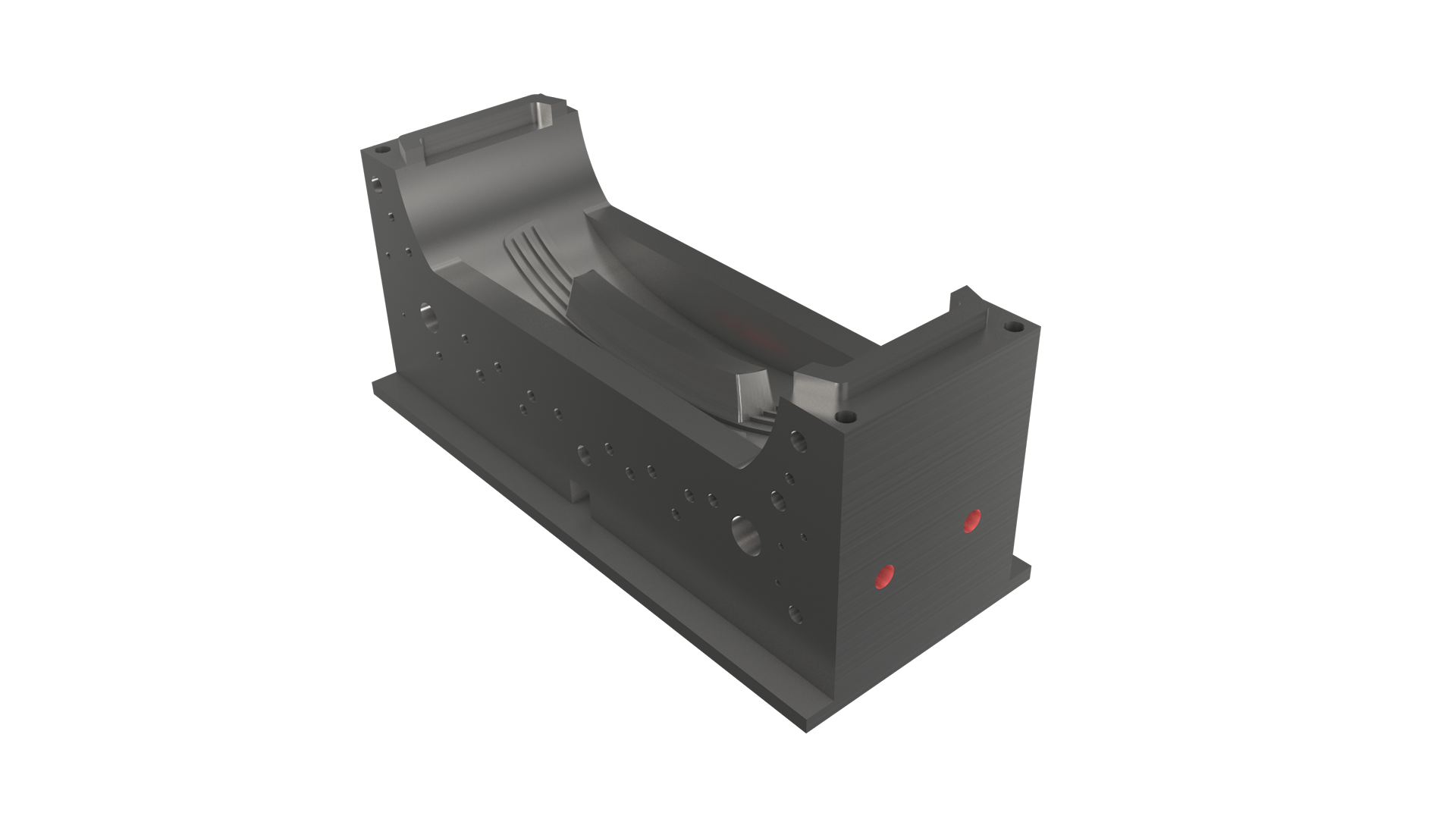

In the world of Industry 4.0, the need for improved machine utilization is met thru high feed machining strategies in milling, turning and grooving.

The cleanest-cutting countersinks available! Two ultra-deep flutes clear chips with remarkable efficiency and leave a perfectly clean rim, ...

When posted, it is a perfectly sized writer. That’s what pocket pens do the best. Capped, they can hide away in a pocket or a pouch. Uncapped and posted, the are full-sized writing workhorses.

Materialremoval rateformula for milling

I had just seen Ian at the Philadelphia Pen Show five weeks prior, and even got to tour his workshop as part of a group during that event. The Pocket Six had recently been launched, and I made sure to purchase my second one, with the newly-added Jowo nib compatible grip section.

Membership starts at just $5/month, with a discounted annual option available. To find out more about membership click here and join us!

We are amid the fourth industrial revolution (Industry 4.0). Manufacturing industry is bracing new technologies, helping them in improving machine utilization. CNC mills and CNC lathes are being built to perform metal cutting operations at never before speeds. As a cutting tool partner, Tungaloy has enjoyed developing equally good metal cutting tools for these new generation CNC mills and lathes.

Tungaloy offers a unique advantage to customers with its High Feed milling cutters. It offers flexibility in selecting the approach angles, based on the tool overhang, maximum depth of cuts required and the material being machined. Refer the above image. MillQuadFeed cutters offer two distinct inserts (ZER and UER), which offers 12° and 7° approach angle, when used on the same cutter body. The UER insert offers excellent stability while machining difficult-to-cut materials, like stainless steel, nickel- based alloys and titanium alloys, without compromising the metal removal rates. Whereas the ZER insert helps customers optimize the DOC on a high torque machine. It is also a great idea to use ZER to machine the top scaled layer of a component which generally poses a challenge with its hardness and uneven surface

Materialremoval ratein milling

This pen represented a big change in the Schon DSGN lineup. The pen bodies had always been minimally styled, with the addition of wild anodizing taking the pens up a notch in the recent years. But to modify the base cylinder with a design as complex as these facets? Well, these just jumped off the table when people saw them in Baltimore, and quickly made their way over to me.

However, HSM became and still remains popular for finishing operations of tough to machine materials and hardened steels. HSM yielded better results with surface quality and profile machining operations, which required blending of fine curves to improve the aesthetics of the machined part, however, it has not been popular as a process for roughing to semi finishing operations. HSM also remained popular for use with smaller diameter tools and end mills, mostly on hardened steels, especially carbide ball and bull nose end mills.

High feed machining relies on the chip thinning effect. The below images of a 90° shoulder mill, a 45° face mill and a 15° – 17° high feed cutter, provides two distinct points –

I see a lot of pens for the first time at pen shows, so why does this one stick out more than most? Well, have you seen it? That’s what people kept telling me as they were bringing them over to me see at the 2020 Baltimore Pen Show - aka the last pen show I attended in person.

Fast-forward those handful of weeks to Baltimore, where I had brought Nock Co. to put in some hours behind the table, instead of mixing and mingling, as I did in Philly. Knowing my love for Schon DSGN pens, my “friends” started appearing at my table with their latest purchase that they couldn’t wait to show me. Yes, this very bright, shiny, and beautiful faceted brass Pocket 6. Ian had been very busy since I last saw him!

Posting is key for pocket pens, and the Pocket Six design handles that with threads on the end of the barrel to attach the cap to. It takes less than two turns to uncap the pen, and then the same amount to post, so it is a relatively fast process.

MaterialRemoval Rateformula for drilling

TUNGALOY-NTK AMERICA INC. 3726 N. Ventura Drive Arlington Heights, Illinois, 60004, U.S.A. Phone: +1-888-554-8394 Fax: +1-888-554-8392

With high feed turning, the radial load is higher than the axial feed force. Therefore, applications typically vary from large diameter roll machining, facing on large CNC lathes to huge casting machining on vertical turret CNC lathes.

The STH CBN tipped inserts offer high feed turning of hard parts. These new CBN tipped grooving inserts are capable of feed of up to 1.2mm/rev for a DOC of about 0.1mm.

Pen shows are back on the schedule in the US. For how long? Who can really say at this point. I’ve missed attending them, that’s for sure, because the memories made at these events are worth more than any pen or ink or paper that I bring home.

Albania (ALL L), Algeria (DZD د.ج), Andorra (EUR €), Angola (USD $), Anguilla (XCD ... Côte d'Ivoire (XOF Fr), Croatia (EUR €), Curaçao (ANG ƒ), Cyprus (EUR ...

High feed machining is associated with higher metal removal rates (MRR). Working with low depth of cuts and high feed per revolution and at applicable cutting speeds for a given material, high feed machining helps in –

Tungaloy has been in the forefront of developing innovative solutions for High Feed Machining (HFM). It has championed this process of machining, equally well in turning, milling and grooving applications.

Enjoy reading The Pen Addict? Then consider becoming a member to receive additional weekly content, giveaways, and discounts in The Pen Addict shop. Plus, you support me and the site directly, for which I am very grateful.

Products – Harvey Tools. Filter by. All, Accessories · Band Saw · Bridge City Tool Works · Chopstick Master · Drilling · Dust Collector · Dust Processor ...

Unlike most other manufacturers inserts, this combination ensures a consistent high quality thread, with precise shape and dimensions. Two different unique ...

Why do I bring this up at the beginning of this review? Because a pen show is where I first saw the Schon DSGN Pocket Six Faceted Brass Fountain Pen.

The new AddMultiTurn makes turning operations more versatile and flexible. It uses the chip thinning effect to its advantage, for high feed, back turning. This tool can be applied on any type of CNC lathe. With its unique insert shape, the radial loads are lower, leading to stable cutting on slender parts.

0086-813-8127573

0086-813-8127573