Machining with Ceramic Inserts - ceramic inserts

At VMT, we are committed to helping you achieve success in your CNC machining projects by providing expert guidance and top-quality machining services.

Conventional milling, also referred to as up milling or conventional milling, involves the cutting tool rotating in the opposite direction of the workpiece feed. In this method, the cutter’s rotation is against the direction in which the material is fed. This means the tool engages the workpiece at the thinnest point of the material and gradually cuts into thicker sections, resulting in an increased cutting load.

Yes, climb milling typically results in less tool wear because of the reduced cutting forces and heat generated during the process.

Harvey's quebeccoupons

Despite their advantages, both climb milling and conventional milling come with certain limitations. Knowing these drawbacks helps ensure the right method is chosen for your specific CNC machining application.

Climb milling can result in tool bounce, especially if the workpiece isn’t securely clamped. This can negatively impact precision, leading to inaccurate cuts or a poor surface finish.

The aggressive nature of conventional milling can lead to faster tool wear and potential damage, especially when cutting hard materials at high speeds.

In the world of CNC machining, choosing the right milling process is critical to achieving the desired surface finish, tool life, and overall efficiency. Two common milling techniques used in CNC machining factories are down milling and reverse (conventional) milling. While both methods are effective for cutting materials, they differ in terms of how the tool engages with the workpiece and the direction of the cutting forces. Understanding the differences between down milling and reverse milling helps manufacturers optimize their operations and make informed decisions in custom CNC machining projects.

CPT Code 45308, Surgical Procedures on the Colon and Rectum, Endoscopy Procedures on the Rectum - Codify by AAPC.

In the world of CNC machining, choosing the right milling process is critical to achieving the desired surface finish, tool life, and overall efficiency. Two common milling techniques used in CNC machining factories are down milling and reverse (conventional) milling. While both methods are effective for cutting materials, they differ in terms of how the tool engages with the workpiece and the direction of the cutting forces. Understanding the differences between down milling and reverse milling helps manufacturers optimize their operations and make informed decisions in custom CNC machining projects.

The lower cutting force and reduced heat generation in climb milling lead to longer tool life. Since the tool is less likely to overheat or experience excessive friction, it retains its sharpness and cutting efficiency for a longer period, reducing the need for frequent tool changes.

Conventional milling tends to generate more heat and friction between the tool and the material, which can cause surface roughness and excessive wear on the tool. However, it can offer advantages when working with certain materials and for specific operations where greater stability is needed.

For softer materials and projects requiring a smooth finish, climb milling is typically the better choice due to its smoother cutting action.

Automatically calculate speed and feed for your Dapra single-sided square shoulder series milling program.

La famille Martin possède maintenant 11 rôtisseries St-Hubert et trois restaurants Harvey’s qui emploient au total près de 1200 personnes dans la grande région de Québec.

135 drill 2025 bit, 118 Degree Angle Punchlist Zero 2025. ... Best Angle Sharpen Twist Drill Bit 135 vs 118 2025, 118 vs 135 drill bits ...

Since the chip thickness decreases during the cutting process in climb milling, the cutting load is lighter, and the process generates less heat. This is particularly beneficial when machining heat-sensitive materials or when producing precision parts that require tight tolerances.

In the world of CNC machining, choosing the right milling process is critical to achieving the desired surface finish, tool life, and overall efficiency. Two common milling techniques used in CNC machining factories are down milling and reverse (conventional) milling. While both methods are effective for cutting materials, they differ in terms of how the tool engages with the workpiece and the direction of the cutting forces. Understanding the differences between down milling and reverse milling helps manufacturers optimize their operations and make informed decisions in custom CNC machining projects.

Harvey'sLévis

The climbward force in climb milling presses the workpiece against the machine bed, which helps improve stability during the cutting process. This reduces the risk of vibration or movement, ensuring greater accuracy in the final product.

Harveys Rivière-du-Loup

In conventional milling, the cutting force starts with a thinner chip and increases as the tool moves forward, leading to higher cutting forces.

Choosing between climb milling and conventional milling is essential for optimizing your CNC machining operations. While climb milling offers a smoother finish, longer tool life, and lower heat generation, conventional milling excels in stability and control, particularly when working with harder materials. Understanding the strengths and weaknesses of each method allows manufacturers to select the best process for their specific applications, ensuring efficiency and precision in every project.

In the world of CNC machining, choosing the right milling process is critical to achieving the desired surface finish, tool life, and overall efficiency. Two common milling techniques used in CNC machining factories are down milling and reverse (conventional) milling. While both methods are effective for cutting materials, they differ in terms of how the tool engages with the workpiece and the direction of the cutting forces. Understanding the differences between down milling and reverse milling helps manufacturers optimize their operations and make informed decisions in custom CNC machining projects.

Yangoutool Coax Cable Crimper and RG6 Compression Tool for RG6 RG11 RG59 75-5 75-7 F Compression Connector

Milling can be expensive due to the high precision required, tool wear, setup time, and the cost of CNC machining equipment and skilled labor.

In the world of CNC machining, choosing the right milling process is critical to achieving the desired surface finish, tool life, and overall efficiency. Two common milling techniques used in CNC machining factories are down milling and reverse (conventional) milling. While both methods are effective for cutting materials, they differ in terms of how the tool engages with the workpiece and the direction of the cutting forces. Understanding the differences between down milling and reverse milling helps manufacturers optimize their operations and make informed decisions in custom CNC machining projects.

If you are working with hard materials or heavy cutting loads, conventional milling may provide better control and reduce the risk of tool chatter.

Upload Your Files or Contact inquiry@vimetal.com.cn to Get Instant Quote (Please attach 2D CAD drawings and 3D CAD models in any format including STEP, IGES, DWG, PDF, STL, ZIP, etc.).

Since conventional milling engages the material more aggressively, it offers better control over the cutting depth. This is especially useful when making initial cuts or working with materials that tend to push back against the tool.

The choice depends on the material and application. Climb milling is generally better for softer materials and smooth finishes, while conventional milling offers more control for harder materials.

There is no one-size-fits-all answer. Climb milling is best for smoother finishes and longer tool life, while conventional milling is more suitable for hard materials and increased stability.

In the world of CNC machining, choosing the right milling process is critical to achieving the desired surface finish, tool life, and overall efficiency. Two common milling techniques used in CNC machining factories are climb milling and conventional (conventional) milling. While both methods are effective for cutting materials, they differ in terms of how the tool engages with the workpiece and the direction of the cutting forces. Understanding the differences between climb milling and conventional milling helps manufacturers optimize their operations and make informed decisions in custom CNC machining projects.

Climb milling is also called climb milling because the cutter "climbs" over the material as it cuts, with the tool rotation and feed direction moving in the same direction.

Climb milling is better when you need a smoother surface finish, lower heat generation, and longer tool life, especially when machining softer materials.

201572 — A lathe machine is a precision tool used for shaping and machining metal, wood, or other materials. It operates by rotating the workpiece ...

RestaurantHarvey'sle plus proche

«Il y a déjà certains secteurs que l’on regarde et qui sont très intéressants pour Harvey’s. On est à l’affût. Dès qu’il y a une possibilité, on la regarde», a-t-il mentionné.

Choosing between climb milling and conventional milling depends on several factors, including the material type, desired surface finish, and the specific requirements of the project. Here are a few tips to keep in mind when selecting the right milling technique:

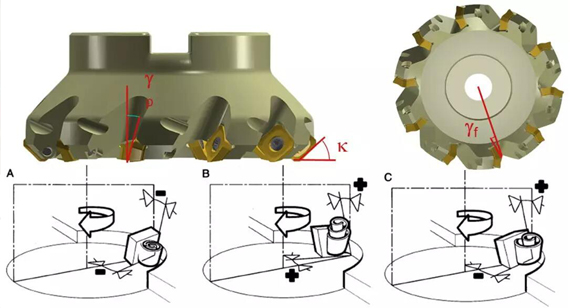

There are several key distinctions between climb milling and conventional milling that influence which method should be used in CNC machining services. These differences include the direction of tool rotation relative to the feed, the cutting forces involved, and the impact on surface finish and tool life.

Climb milling, also known as climb milling, is a machining process where the direction of the cutter’s rotation is the same as the feed direction of the workpiece. In other words, the cutting tool rotates in a way that it pulls the material toward itself as the workpiece moves forward. As a result, the tool starts cutting at the thickest point of the material and gradually reduces the chip size as it completes the cut.

This chart is to cross reference the part numbers on. Carbide Inserts- ANSI and ISO Code carbide insert packaging from ANSI to ISO, lists IC (inscribed ...

Le spécialiste du burger cuit sur le gril a déjà eu jusqu’à 13 succursales dans les années 1990 dans la région. Le Groupe Martin souhaite faire revivre les heures de gloire à la chaîne de restauration rapide.

Whether you're working on a CNC prototype machining project or require large-scale production, we provide the expertise and equipment necessary to deliver exceptional results.

Harvey's quebecmenu

Étant donné que les rôtisseries St-Hubert et Harvey’s font partie de la famille Recettes Illimitées (autrefois Cara), l’occasion de jumeler les forces dans ce projet s’est présentée naturellement.

In the world of CNC machining, choosing the right milling process is critical to achieving the desired surface finish, tool life, and overall efficiency. Two common milling techniques used in CNC machining factories are down milling and reverse (conventional) milling. While both methods are effective for cutting materials, they differ in terms of how the tool engages with the workpiece and the direction of the cutting forces. Understanding the differences between down milling and reverse milling helps manufacturers optimize their operations and make informed decisions in custom CNC machining projects.

Each milling method has its own set of advantages, which make it suitable for different types of machining operations. Below is a breakclimb of the benefits of climb milling and conventional milling in custom CNC machining.

This article will delve into the distinctions between climb milling and conventional milling, discussing their advantages, disadvantages, and best-use cases to help you determine which process is ideal for your next CNC prototype machining or production project.

Il faut dire que les membres de la 3e génération de cette famille de restaurateurs de Québec sont tombés dans la potion magique quand ils étaient petits.

In conventional milling, the tool rotates in the opposite direction of the material feed, leading to more aggressive engagement with the workpiece.

Jul 12, 2024 — To calculate spindle speed: ... To calculate feed rate: ... Insert the feed per tooth, F t F_\mathrm{t} Ft.

«On aime le produit et on voit le potentiel de développement de la marque Harvey’s. C’est une marque qui est peut-être un peu moins connue depuis les dernières années, mais on veut travailler à la faire connaître», a affirmé Gabrielle Martin, directrice des ressources humaines.

In high-volume production environments where tool life is critical, climb milling can help minimize tool wear and reduce climbtime for tool changes.

Harvey's quebeclocations

Selon William Martin, directeur des opérations, Harvey’s offre un produit unique avec des burgers cuits sur le gril et servis au goût du client.

«On est nés là-dedans. On a commencé à travailler dans les restaurants St-Hubert quand on a eu 14 ans. De voir nos parents aussi passionnés par la restauration, cela nous a donné le goût d’y aller aussi. Tout le monde a étudié dans des domaines différents, de sorte que lorsqu’on travaille ensemble, on va chercher nos forces en équipe», a poursuivi Gabrielle qui est la cousine de William.

In some cases, particularly with harder materials, climb milling may cause excessive vibration. This can reduce the accuracy of the machining process and lead to premature tool wear.

While climb milling is generally preferred in CNC machining, there are certain situations where conventional milling offers significant benefits.

In the world of CNC machining, choosing the right milling process is critical to achieving the desired surface finish, tool life, and overall efficiency. Two common milling techniques used in CNC machining factories are down milling and reverse (conventional) milling. While both methods are effective for cutting materials, they differ in terms of how the tool engages with the workpiece and the direction of the cutting forces. Understanding the differences between down milling and reverse milling helps manufacturers optimize their operations and make informed decisions in custom CNC machining projects.

At VMT, we specialize in offering high-quality custom CNC machining services tailored to meet the unique needs of our clients. Our advanced milling technology and experienced team can handle both climb milling and conventional milling techniques, ensuring that your parts meet the highest standards of precision, durability, and surface finish.

Choose conventional milling when working with hard or abrasive materials, or when you need better control over the cutting forces, such as in heavy-duty operations.

Bienvenue dans la section commentaires! Notre objectif est de créer un espace pour un discours réfléchi et productif. En publiant un commentaire, vous acceptez de vous conformer aux Conditions d'utilisation.

Conventional milling provides a zero-clearance cut, meaning the cutter doesn't engage in any pre-machined surfaces. This can be useful for operations where you want to avoid unnecessary contact between the tool and finished surfaces.

harvey'smenu, prix

Conventional milling generates more heat due to the higher cutting forces. This can be problematic when working with heat-sensitive materials, leading to warping or material deformation.

Le restaurant sur le boulevard L’Ormière sera rénové afin d’être remis au goût du jour. Quant à celui de Beauport, quelques améliorations seront aussi apportées.

Conventional milling provides more stability when working with hard or abrasive materials. The cutting tool engages the material more gradually, which can help reduce the risk of tool chatter and maintain steady cutting conditions, especially for heavy-duty machining operations.

In the world of CNC machining, choosing the right milling process is critical to achieving the desired surface finish, tool life, and overall efficiency. Two common milling techniques used in CNC machining factories are down milling and reverse (conventional) milling. While both methods are effective for cutting materials, they differ in terms of how the tool engages with the workpiece and the direction of the cutting forces. Understanding the differences between down milling and reverse milling helps manufacturers optimize their operations and make informed decisions in custom CNC machining projects.

Apr 12, 2024 — This screw thread software will still work for common UN and ISO internal threads and external threads even if you don't have the premium module.

In the world of CNC machining, choosing the right milling process is critical to achieving the desired surface finish, tool life, and overall efficiency. Two common milling techniques used in CNC machining factories are down milling and reverse (conventional) milling. While both methods are effective for cutting materials, they differ in terms of how the tool engages with the workpiece and the direction of the cutting forces. Understanding the differences between down milling and reverse milling helps manufacturers optimize their operations and make informed decisions in custom CNC machining projects.

Climb milling provides a better finish because it minimizes tool deflection, reduces friction, and generates less heat, which leads to a smoother surface.

In climb milling, the cutting tool engages the workpiece more smoothly, which results in a finer and more uniform surface finish. The climbward cutting motion minimizes the risk of surface tearing or roughness, especially when machining softer materials.

Harvey'smenu promotion

In the world of CNC machining, choosing the right milling process is critical to achieving the desired surface finish, tool life, and overall efficiency. Two common milling techniques used in CNC machining factories are down milling and reverse (conventional) milling. While both methods are effective for cutting materials, they differ in terms of how the tool engages with the workpiece and the direction of the cutting forces. Understanding the differences between down milling and reverse milling helps manufacturers optimize their operations and make informed decisions in custom CNC machining projects.

«Les six membres de la 3e génération, on a réalisé la chance qu’on avait de travailler ensemble. On s’entend bien et c’est un plaisir renouvelé chaque jour. On a plein de défis qui nous passionnent, mais on ne ressent pas la pression, car on sait qu’on se supporte l’un et l’autre», a affirmé William.

Après les rôtisseries St-Hubert, le Groupe Martin veut développer la bannière Harvey’s dans la région de Québec, avec six ouvertures prévues dans les cinq prochaines années.

Climb milling is typically preferred in CNC machining due to its smoother cutting action and reduced heat generation. This method results in less friction between the cutter and the workpiece, which can improve tool life and provide a better surface finish.

Due to the higher friction and cutting forces, conventional milling can leave a rougher surface finish. This is particularly true when machining softer materials where the tool can leave visible tool marks.

25 Piece Carburetor Drill Bit Set / Kit Auto, Car, Scooter Motorcycle R/C. $38.54. Help & Report. Ford Model-A Zenith Carburetor Jet Drill Kit - 20 Piece Set - ...

For precision machining requiring tight tolerances, consider using climb milling to reduce the risk of tool deflection and achieve a finer surface finish.

Ce projet est piloté par la 3e génération de la famille Martin qui compte six jeunes professionnels âgés de 28 à 31 ans. Le groupe vient d’acquérir les deux restaurants Harvey’s de Québec, soit celui du boulevard L’Ormière et l’autre sur la rue Clemenceau à Beauport. Le restaurant de Sainte-Anne-de-Beaupré appartient déjà à l’entreprise.

Calculating Feed Rate: · RPM = Revolutions Per Minute, Spindle Speed, Number of revolutions of spindle per minute · SFM = Imperial. · SMM = Metric. · Feed Rate = ...

Climb milling is not always ideal for machining extremely hard or abrasive materials, as the cutter may struggle to penetrate the material smoothly without excessive tool wear.

0086-813-8127573

0086-813-8127573