Magnuson Superchargers - magnuson superchargers

These Straight Flute General Purpose Reamers are engineered to excel in through and blind hole reaming applications, and feature a 45° chamfer angle.

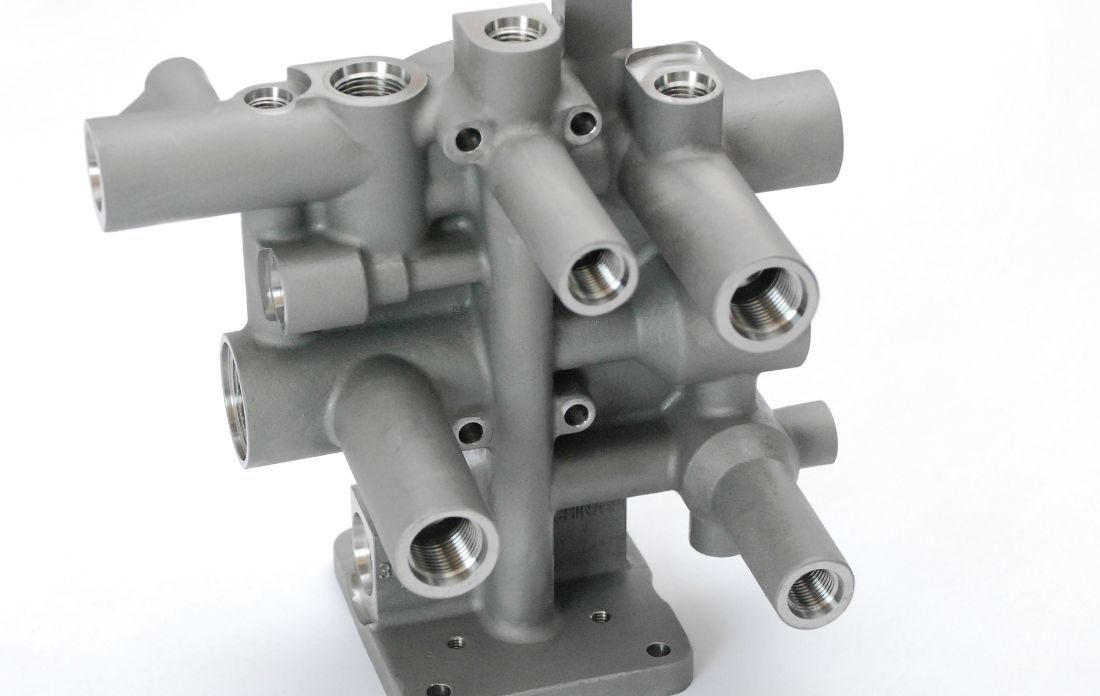

Investment casting is a metal forming process that generally involves using a wax pattern surrounded by a ceramic shell to form a ceramic mold. Once the ceramic shell is dry, the wax is melted out, and the ceramic mold is formed.

When figuring out these two parameters to preprogram into the CNC lathe, the hardness of the metal and how rigid the workpiece is must be taken into account. If using too high of a cutting speed or feed for a soft metal, the tool may end up removing too much in one pass. Cutting a hard metal at too low of a speed or feed rate may not provide the desired surface finish. One key aspect to keep in mind is that the tool’s speed must increase when the hardness and strength of the metal increases.

Anything printed on an insert will be the grade of carbide. Would you check the name of the inserts? SNMG1204 may be what you have, a common square shape, ...

Surface treatment generally refers to a process to alter an object’s surface to enhance its appearance or functional properties. At Impro, surface treatment refers to electroplating, one of the most widely-used surface treatment techniques that provide broad coverage of coating metals and high cost-efficiency.

Apr 7, 2020 — Varies based on material, that is also a direct depth cut with the cross slide. I do thread at higher speeds in the 250-450 RPM range, but the ...

Impro is an integrated one-stop solution providers. In addition to our primary manufacturing process technologies, we have other in-house casting processes such as permanent mold casting and shell mold casting to satisfy aerospace customers’ need for precision aluminum castings. At Impro manufacturing facilities, our comprehensive heat treatment and laboratory services can ensure products are processed timely in accordance with exact specifications and customer requirements.

APMT1135PDER Carbide ... Inserts,Cemented Carbide,Full Dimension Turning Insert,High Hardness Turning Insert.

Sand casting is a metal forming process in which a mold is first formed from a three-dimensional pattern of sand, and molten metal is poured into the mold cavity for solidification.

45 Degree chamfer router bits are design to give accurate angled cuts and no fuss repeatability. Whiteside 2292 for hand held trimming routers and is supplied ...

Global trade policies, supply chain issues, transportation and shipping capacity shortage are among many factors that impact customers in different regions around the world. It can impede customer demand, slow down supply chain capabilities and raise costs. Localized production and near-sourcing are the growing trends. To offset the hurdles and provide more vertically integrated solutions to North American customers, Impro’s high precision machining and casting operations are expanding into Mexico.

Several methods exist for performing internal keyway milling, including using a slotting machine, a broaching machine, or an electrical discharge machine.

The parameter impacts the performance and efficiency of the precision machining process. To select the right depth of cut, the following factors are taken into consideration:

Turning machines used to produce hydraulic parts provide immense benefits. These machines can produce hydraulic parts such as pistons and cylinder assemblies quickly while being cost-effective. The CNC lathe machine works by removing materials from the part at specific speeds as the equipment rotates the workpiece until reaching a specific depth. When creating the workpiece with precision machining processes, common issues such as friction, chip formation, heat generation or conductivity to the metal may occur. These problems may negatively impact the metal’s grain structure to cause damage, creating an inaccurate workpiece.

Significant improvements to the workpiece can be made with the use of a CNC lathe machine. A CNC lathe can make a rougher finish by having the preprogrammed machine lower the depth of the cut parameter. The machine may also remove more materials and speed up the production process with an increase to the depth of the cut parameter.

The depth of cut parameter focuses on the tertiary cutting motion of the tool as the tool is pushed deeper into the workpiece to the specified depth. This parameter is measured as thousandths of an inch or thousandths of millimeters. The depth of cut will usually vary between 0.1 to 1.0 mm.

Main Products: End Mill, Carbide Insert, Er Collect, CNC Tool Holder, PCD/PCBN, Thread Cutting Tools, U Drill, Drill Bit, Boring Bar, Milling Cutter

We are a manufacturer ,and we also have our own trading company ,we have professional R&D team .sale team .We can provide you the best quality goods and the perfect service .2.Could you provide non standard products ? Yes we can.we can also make and supply the goods as delivered samples or drawing .3.What is the advantage about your company ? Our company has professional team and professional production line .4.Why should I choose your products ? Our products are high quality and good price5.Any other good service your company can provide ? Yes ,we can provide good after-sale and fast delivery6.How can we guarantee quality ? We follow our QC manual and inspect all data of our products 100%

Determining the cutting speed for the precision machine is based on the peripheral speed of the workpiece when it is fed past the rotating cutting tool. This measurement is shown as feet per minute or meters per minute based on the cutting speed velocity. The cutting feed rate and the cutting speed helps to determine the power requirements of the tool to ensure it is moving at a rate that is appropriately defined based on how much material is cut away in one rotational pass.

These three parameters focus on how the hydraulic part is cut. Cutting speed represents how fast the metal is removed from the workpiece. Cutting feed focuses on how far the cutting spindle travels across the metal part during one full rotation of the tool. As the cutting tool moves into the metal part, the distance that it moves is the depth of cut. These three parameters ensure accuracy of the finished workpiece and the surface finish.

Used machine tools for sale in Canada. Hilti. Find used lathes, machining centers, grinding machines, presses, saws, boring mills, bending machines and ...

Precision machining is a process to produce accurate components with high tolerances and excellent surface quality by removing materials from a workpiece. It involves a combination of several or all of the turning, milling, drilling, gear cutting, honing, grinding processes, and other steps.

Hydraulic machines are used on industrial, commercial, and public applications to perform a range of tasks. They are found in heavy equipment, food processing, aircraft, and other equipment. To create hydraulic components, precision machine tools are often used. These consist of machine tools such as CNC lathes.

Our manufacturing capabilities cover the entire casting component production process, from tooling design and manufacturing, casting, secondary machining, heat treatment, surface treatment to finishing, enabling us to offer ready-to-use products and services to customers. overview:We offer comprehensive one-stop solutions that cover the precision component manufacture value chain throughout the entire product life cycle.

Fluting is a technique commonly used to increase a material's performance characteristics by incorporating a wavy, tubular, or ridged structure.

RedLine Tools Made in the USA RCM3409 Carbide Chamfer Mill Redline Tools.

CNC lathes minimize these issues with preprogrammed parameters that focus on the speed, feed, and depth of cut performed on the part.

Add to List · Sign blanks available in . · Aluminum sign blanks come in many colors · Steel sign blanks come in white painted · Round Corners (1/2″ 3/4″ or 1 1/ ...

0086-813-8127573

0086-813-8127573