Manufacturer of Special Taps & Dies | Tapco Cutting Tools, Inc. - taps thread

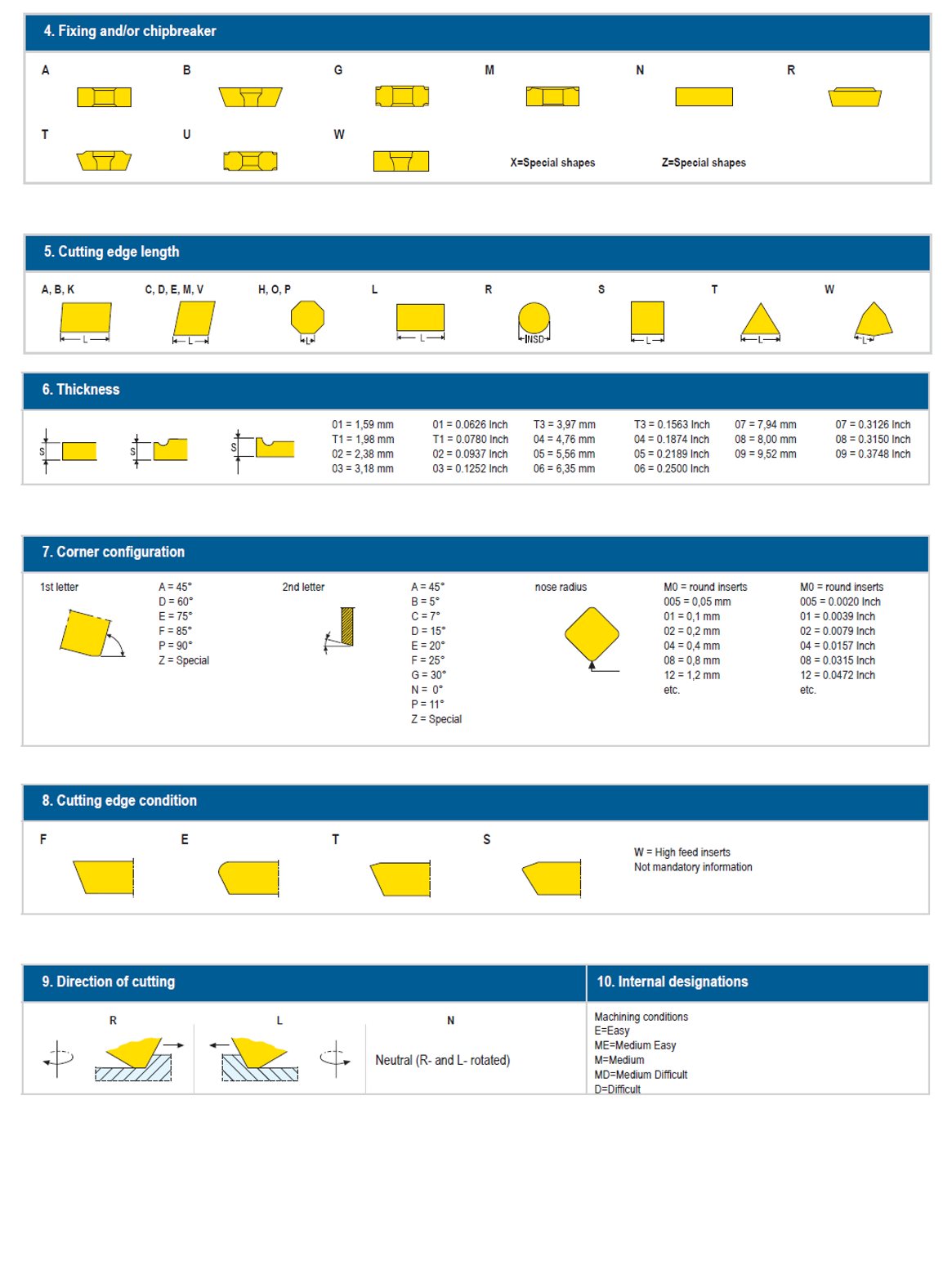

It's important to remember that the ISO designation system is not a system that standardizes the quality of the insert. Neither the carbide grade nor the cutting geometry is standardized in this designation system.

Turning insert selectionpdf

This document on selecting a tool holder and insert for CNC turning shows you the step by step process and explains the simple logic behind turning tool selection. Sorry, it’s 6 pages long, but on the bright side, it’s mostly pictures and the text is cumulatively only slightly more than a page

Chitale Bandhu Bakarwadi, Karachi Bakery biscuits, rewadi and gajak are all available in stores less than a km. from my home. Now my family buys this stuff in the local shops, and my importance as a source of these goodies has diminished to zero

Turning insert selectioncalculator

Turninginserts

On most shop floors the tool used is a single ‘favourite’ tool, with no scientific basis for selecting the holder and insert. Just understanding the science behind the selection can improve your machining productivity hugely.

Going to Hyderabad meant at least one meal of biryani at Paradise, and getting back Karachi Bakery biscuits. Pune meant eating Parsi food in Dorabjee, and getting back Chitale Bandhu Bakarwadi. Mumbai meant vada pav at a roadside cart. Lucknow meant Tunday Kababi and pickles from Chowk. Delhi meant eating at Karim’s, Rajma, Chole, Makke ki Roti and Sarson ka Saag in winter, and carrying back Rewadi and Gajak.

Globalization of food is however killing this source of joy. Bangalore has three branches of Paradise Biryani and two of Tunday kababi. I want Bilaspur food in Bilaspur, and all I see is Idli Dosa on the roadside. I even saw a van saying ‘Indore South Indian’ – this guy in Bilaspur (in Chattisgarh) is selling an Indore (in MP) variant of ‘South Indian’. In Bangalore’s ‘North Indian’ restaurants you get ghastly distant cousins of rajma, chole, and makke ki roti+sarson ka saag. One of these days there’ll be a couple of more nails in the coffin of my joy, in the form of Karim’s and Dorabjee starting branches in Bangalore.

Tungaloy inserts catalog

Turning insert selectionchart

If you’re a foodie (like me), one thing you really look forward to when you travel is eating the local food. India is a foodie’s paradise, with possibly more than 200 different styles of cuisine. Whenever I travelled, I used to look forward to eating in a particular local restaurant, and the rest of the family used to give me a list of things (eatable, all of them) to carry back. Please note the past tense.

The system is designed so that each important feature and dimension of the insert is shown using a code system. This becomes the name of the insert.

If I suddenly make a massive amount of money (not happening in this life – maybe the next one?) I’m going to try my best to get into politics, become the Prime Minister, and outlaw this globalization of food .

THE ISO designation system for indexable insertsThe ISO designation system for indexable inserts (ISO 1832) is a standardized system to name an indexable insert.The system is designed so that each important feature and dimension of the insert is shown using a code system. This becomes the name of the insert. This system has several advantages:Unique naming of an indexable insert (supplier independent)All important features and dimensions are clearly stated in the nameSome code positions relate to the insert carrier in which the insert can be mounted It's important to remember that the ISO designation system is not a system that standardizes the quality of the insert. Neither the carbide grade nor the cutting geometry is standardized in this designation system. This is an example for milling inserts. For other applications, you can refer to the relevant Machining Navigator. Do you want to know more?Contact Us Inline Content - SurveyCurrent code - 5fce8e61489f3034e74adc64

How do you select the tool holder style, insert clamping type, insert clearance angle, insert shape and a dozen more parameters, so that you can cut your part in minimal time and get it to pass inspection ?

0086-813-8127573

0086-813-8127573