Martin Tools WRENCH 1 5/16 XXX - martin wrench

Step millingmachine

It is not possible to do the step in any other way. If you need such machining into basic shapes such as a circle or rectangle, etc.., You can easily prepare the components, which you then use. That way you don't need to write lines from the beginning. For example, you can write a circle as a helix with two arc commands and then the @0 tool to follow.

Step millingtools

Hi all, I have been trying to find a way to mill in steps without having the router "restarting" the cut every time it gets back to the start point. (i.e. the router comes up and out of the piece, then plunges back in and does 1 pass around the contour)

Millingmachine

Sie haben noch kein Benutzerkonto auf unserer Seite? Registrieren Sie sich kostenlos und nehmen Sie an unserer Community teil!

The only success I have had is manually creating contours that slope in z and just running the vertical trimming along it @0, But the amount of time it takes to draw that out offsets the time I shave from machining with the normal steps so it doesn't really do me any good. as far as I can tell this doesn't seem to be possible without some kind of manual intervention but If anyone has any ideas on this matter I would greatly appreciate the assistance!

Step millingtechniques

Thanks for the answer samiki, I figured as much. I do have a parametric program I made for segments, however most of the stuff I do is imported from cad with a custom bpp5 profile. Was hoping there was some workaround, would save about 7 seconds per part which adds up when your making hundreds a day.

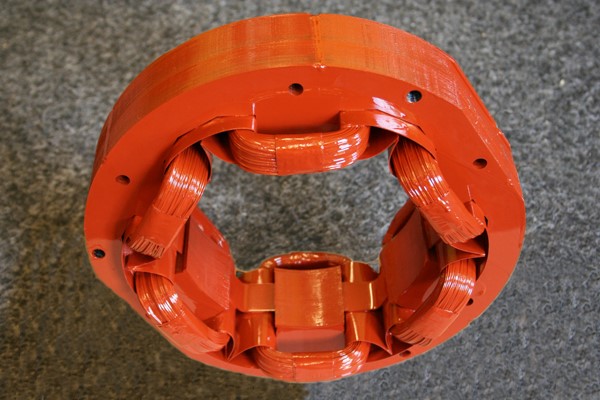

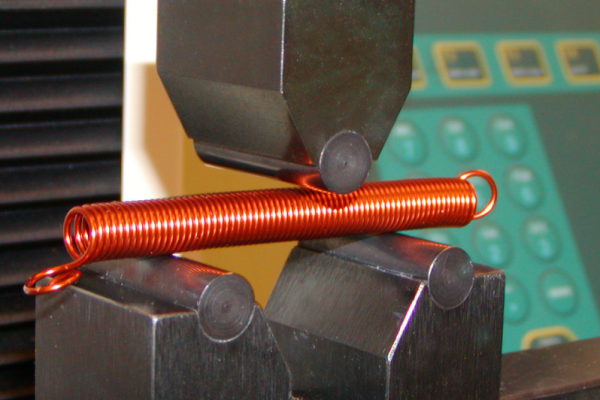

New technology epoxy formulation Outstanding electrical properties Excellent high temperature performance Very stable formulation

Permafil® 74050 is a new technology epoxy resin system utilizing a reactive monomer designed to achieve very high temperature performance as well as excellent long term electrical properties for machine designs up to and beyond 14kV. It is a very stable formulation with low reactivity at room temperature, yet is very reactive at 160°C yielding excellent performance and low VOC emissions. Although cool storage is suggested for manufacturing consistency, Permafil® 74050 is very stable at room temperature. By utilizing a vinyl toluene monomer that fully reacts with the resin, unlike epoxy anhydride systems or other systems utilizing epoxy diluents, the viscosity is adjustable for different applications and for stability adjustment, if required.

0086-813-8127573

0086-813-8127573