Mastering the Picatinny rails: Tips and Tricks form Beginner ... - mil std 1913 rails

With our proprietary finishing process, we can resharpen diamond tools regardless of where they were manufactured, delivering a reliably smooth edge every time.

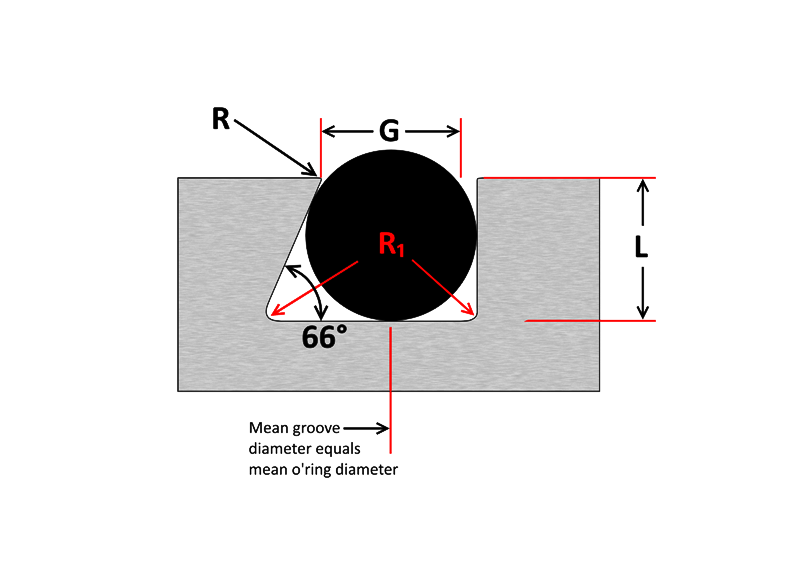

Note: Top radius (R) is a critical dimension; too small a radius can damage the seal during installation, while excess radius can lead to extrusion failure.

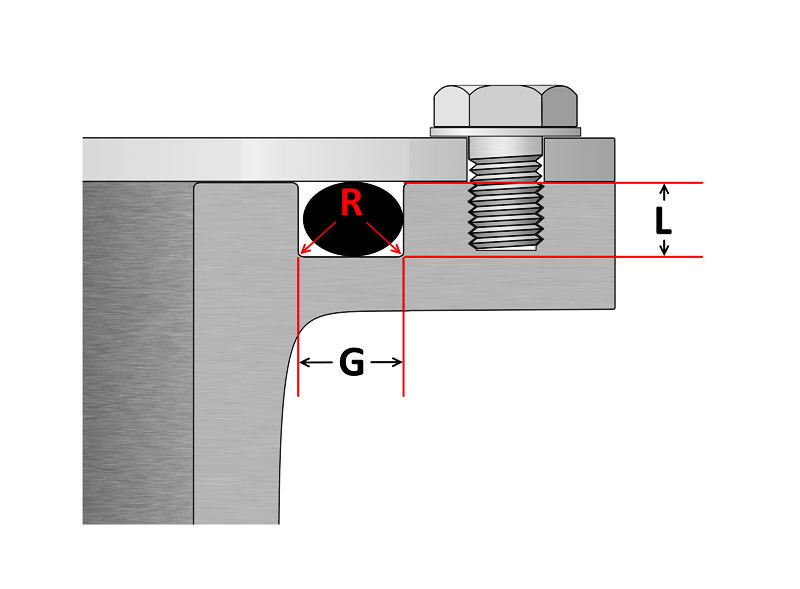

O’ring CSMinimum SqueezeGroove Width (G) .070 ±.003.005.080 .103 ±.003.006.110 .139 ±.004.007.160 .210 ±.005.008.240 .275 ±.006.010.315

Unlike abrasively finished tools, our chemically machined edges are consistent and reliable right from the start with no breaking-in period required.

Processing of high-performance components for the aerospace industry requires using the best diamond grades and state-of-the-art processing methods. Edge Technologies is capable of developing and manufacturing quality tools to machine these materials.

Our tools can be used in producing camera lenses and LCD panels, mold tool generation, and mobile phone production. We create custom single point diamond tools to suit many applications.

63RMS maximum: For non-critical sealing surfaces such as groove sides32RMS maximum: For static sealing on critical sealing surfaces such as groove base and top.16RMS maximum: For dynamic sealing surfaces and for sealing gases in a face type seal.

Diamondpolish

With a deep understanding of single point diamond tooling and years of experience, our team of diamond tool engineers can create the right tool for any application.

Today’s specialized automotive parts require state-of-the-art processing and production methods. Edge Technologies offers ideal solutions for these tasks and can develop and produce the appropriate tools.

We can deliver custom diamond tools quickly, usually in 2 weeks or less while our competitors often require 12 weeks. Tool resharpening and modifications are also done quickly.

Dimensions apply to all laterally loaded o’rings in static face seal grooves for both liquid pressure and vacuum applications.

Diamond Tech

Static Cylinder Grooves O’ring Cross Section(L) Groove Depth Radial(L) Groove Depth AxialSqueeze Radial %Squeeze Axial %(E) Max Diametrical ClearanceG) Groove W 0 Back-up ±.005G) Groove W 1 Back-up ±.005G) Groove W 2 Back-ups ±.005R) Groove RadiusMax Eccentricity .070.050 – .052.050 – .05422–3219–32.004.095.140.207.005 – .015.002 .103.081 – .083.074 – .08017–2420–30.005.142.173.240.005 – .015.002 .139.111 – .113.101 – .10716–2320–30.006.189.210.277.010 – .025.003 .210.170 – .173.152 – .16215–2121–30.006.283.313.413.020 – .035.004 .275.226 – .228.201 – .21115–2021–29.007.377.410.540.020 – .035.005

High precision is the prerequisite for the complex operations of manufacturing medical instruments. Our mono-crystalline synthetic diamond tools are used in many areas of medical technology, specifically in precision fields like eye surgery.

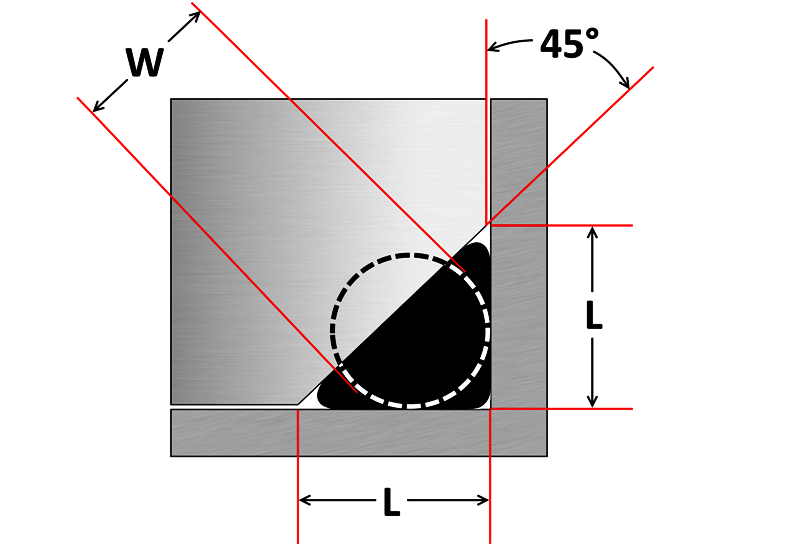

Triangular Crush Groove Cross Section (W)±Groove Depth (L)± (-0) .070″±.003″0.092″+.003″ .103″±.003″0.136″+.005″ .139″±.004″0.184″+.007″ .210″±.005″0.277″+.010″ .275″±.006″0.363″+.015″ 1.50mm±0.08mm1.98mm+0.08mm 2.00mm±0.08mm2.64mm+0.08mm 2.50mm±0.08mm3.30mm+0.13mm 3.00mm±0.10mm3.96mm+0.13mm 4.00mm±0.13mm5.28mm+0.18mm 5.00mm±0.13mm6.61mm+0.25mm 6.00mm±0.15mm7.93mm+0.25mm 8.00mm±0.18mm10.57mm+0.38mm 9.00mm±0.18mm11.89mm+0.38mm

Optics applications require the most precise tools. Our quality diamond tools are frequently used in the defense and military industries where precision is of the utmost importance.

To produce the tailor-made contact lenses and eyeglasses used today, the eye-care industry relies on extremely precise diamond tooling. We have the capability to provide the high degree of precision required.

Our exact process produces a 1000x damage free edge with .25 micron or better form and figure accuracy, allowing us to deliver diamond tools that are superior to those of our competitors.

We offer quick turn-around time, typically delivering our custom tools in 2 weeks compared to the 12 weeks often required by our competitors.

Metric O’ring Groove Dimensions O-Ring Cross Section(L) Cylinder Groove Depth(G) Cylinder Groove Width No Back Up Rings(G) Cylinder Groove Width One Back Up Ring(G) Cylinder Groove Width Two Back Up Rings(L) Flange Groove Depth(G) Flange Groove Width(R) Radius without back up ring(R) Radius with back up ring 1.00.81.4––0.651.40.20.2 1.20.951.7––0.81.70.20.2 1.31.051.8––0.91.80.20.2 1.51.22.1––1.02.10.20.2 1.61.32.2––1.12.20.30.2 1.9 & 2.01.652.53.95.31.42.50.50.2 2.42.03.24.66.01.73.20.50.3 2.52.13.44.86.21.83.40.50.3 2.62.253.65.06.41.93.60.60.3 2.72.33.75.16.51.953.70.60.3 3.02.53.95.36.72.23.90.80.3 3.152.74.05.46.82.34.00.80.4 3.53.14.86.27.62.74.81.00.4 4.03.55.47.18.83.15.41.00.4 4.54.06.07.79.43.46.01.00.4 5.04.36.78.410.13.96.71.00.4 5.54.87.39.010.74.47.31.20.6 5.75.07.79.411.14.67.71.20.6 6.05.38.29.911.64.88.21.20.6 6.355.68.710.412.15.18.71.20.6 6.55.78.910.612.35.48.91.20.6 7.06.19.512.014.55.89.51.50.6 7.56.514.412.915.46.210.41.50.6 8.07.011.013.516.06.611.01.50.6 8.47.511.714.216.76.911.72.00.6 9.07.812.515.017.57.412.52.00.6 9.58.313.315.818.37.813.32.00.6 10.08.713.516.018.58.313.52.00.6 11.09.615.518.020.59.115.53.00.6 12.010.516.819.321.810.316.83.00.6 14.012.219.021.524.011.619.03.00.6 15.013.220.022.525.012.520.03.00.6 16.014.021.524.026.513.521.53.00.6

With a deep understanding of single point diamond tooling and years of experience, our team of diamond tool engineers can create the right tool for any application.

As important as the o’ring seal itself is the groove that the o’ring seats into. The groove must be designed to accommodate not just the o’ring size, but also its intended usage; be it dynamic or static operation, radial or axial loading, vacuum or high pressure.

Diamondpowder

Tech Diamond Toolscoupon

Due to PTFE’s (Teflon®) highly limited deflection ability, the following table has suggested groove dimensions for open face seal (flange) type grooves using imperial PTFE o’rings. PTFE o’rings in radially loaded closed grooves are generally not recommended, however if this is unavoidable, PTFE o’rings can be heated to around 100°C to allow them to become slightly flexible, aiding installation.

With our proprietary finishing process, we can resharpen diamond tools regardless of where they were manufactured, delivering a reliably smooth edge every time.

Diamondstrop compound

We have a team of problem-solvers who will work with you to design and deliver just the right tool needed for any high precision application.

A static triangular crush seal groove is a simple design and ideal when space is limited and/or wall thickness is too thin for a conventional groove. It achieves the same sealing efficiency with either internal or external pressure. However there is very little void space and volume swell can easily lead to extrusion failure. O’rings in triangular crush grooves are permanently deformed once installed, therefore cannot be reused and are discarded after use.

Half Dovetail Groove O’ring CSGroove Depth (L)Squeeze (%)Groove Width (G)Retainer Radius (R)Groove Radius (R₁) .070 ±.003.053 – .05523.064 – .066.005.015 .103 ±.003.083 – .08519.095 – .097.010.015 .139 ±.004.113 – .11518.124 – .128.010.031 .210 ±.005.173 – .17617.190 – .193.015.031 .275 ±.006.234 – .23815.255 – .257.015.062 .375 ±.007.319 – .32314.350 – .358.020.093

Diamondpolishing compound

Unlike abrasively finished tools, our chemically machined edges are consistent and reliable right from the start with no breaking-in period required.

We offer quick turn-around time, typically delivering our custom tools in 2 weeks compared to the 12 weeks often required by our competitors.

Groove Flange O’ring Cross Section(L) Groove DepthSqueeze (%)(G) Groove W Liquid ±0.005(G) Groove W Vacuum ±0.005(R) Groove Radius .070.050 – .05419–32.101 – .107.084 – .089.005 – .015 .103.074 – .08020–30.136 – .142.120 – .125.005 – .015 .139.101 – .10720–30.177 – .187.158 – .164.010 – .025 .210.152 – .16221–30.270 – .290.239 – .244.020 – .035 .275.201 – .21121–29.342 –.362.309 – .314.020 – .035

The following information is a guide for o’ring groove dimensions for both static and reciprocating dynamic applications. The info is based on 70 Shore A Durometer hardness only.

With years of experience in creating custom diamond tools, we can help you problem-solve or work from your sketch or description to create the tool you need for almost any application.

Tech diamond toolsinstructions

Reciprocating Cylinder Grooves O’ring Cross Section(L) Groove DepthSqueeze %(E) Max Diametrical Clearance(G) Groove W 0 Back-up ±.005(G) Groove W 1 Back-up ±.005(G) Groove W 2 Back-ups ±.005(R) Groove RadiusMax Eccentricity .070.055 – .05715 – 25.004.095.140.207.005 – .015.002 .103.088 – .09010 – 17.005.142.173.240.005 – .015.002 .139.121 – .1239 – 16.006.1890.210.277.010 – .025.003 .210.185 – .1888 – 14.006.283.313.413.020 – .035.004 .275.237 – .24011 – 16.007.377.410 .540.020 – .035.005

Dovetail Groove O’ring CSGroove Depth (L)Squeeze (%)Groove Width (G)Retainer Radius (R)Groove Radius (R₁) .070 ±.003.053 – .05523.057 – .061.005.015 .103 ±.003.081 – .08321.083 – .087.010.015 .139 ±.004.111 – .11320.113 – .117 .010.031 .210 ±.005.171 – .17318.171 – .175.015.031 .275 ±.006.231 – .23416.231 – .235.015.062 .375 ±.007.315 – .31916.315 – .319.020.093

Edge Technologies delivers the smoothest, most consistent, and most durable diamond surfaces in the world. Our business is built on this ability to produce a superior edge. Whether in creating custom diamond tools or resharpening tools that require maintenance, we are able to offer our customers surface edges that achieve a smoothness our competitors simply cannot achieve. In addition, we deliver custom diamond tooling solutions, which are effective and often unique. Our extensive expertise allows us to partner with our customers to solve their challenging problems and to do it quickly and with the highest degree of quality.

In a face seal, a dovetail and half-dovetail groove are ideal for holding an o’ring in place during installation and operation. This can allow more streamlined maintenance and shorter downtime with less effort required to secure the seal during installation. Especially handy if the face seal is assembled upside-down. However, due diligence is required when designing a dovetail groove due to limited void space compared to a conventional square groove. This problem can be aggravated by volume swell. Therefore dovetail grooves are not recommended unless end use conditions and their effects upon the seal are thoroughly taken into consideration.

Tech diamond toolsnear me

We have a team of problem-solvers who will work with you to design and deliver just the right tool needed for any high precision application.

THE BENEFITS OF WORKING WITH EDGE TECHNOLOGIES Better Tools Through Better Science Edge Technologies delivers the smoothest, most consistent, and most durable diamond surfaces in the world. Our business is built on this ability to produce a superior edge. Whether in creating custom diamond tools or resharpening tools that require maintenance, we are able to offer our customers surface edges that achieve a smoothness our competitors simply cannot achieve. In addition, we deliver custom diamond tooling solutions, which are effective and often unique. Our extensive expertise allows us to partner with our customers to solve their challenging problems and to do it quickly and with the highest degree of quality.

0086-813-8127573

0086-813-8127573