Maximum amount of tools for the bot to use? - API - tools maximum

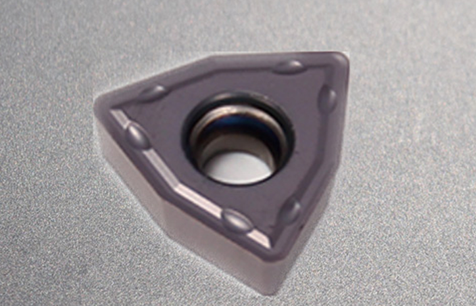

Betalent carbide make carbide make standard carbide turning inserts, for example classical turning inserts DCMT11T304, DCMT11T308, WNMG080404, WNMG080408, WNMG080404R, WNMG080408R, TNMG160404R, TNMG160404R, TNMG160404R/L-VF, TNMG160408R/L-VF, DCMT11T304-MT, DCMT11T308-MT, TCMT090202MT, TCMT090204MT,CCMT09T304-MT, CCMT09T308-MT, WNMG080404-43, WNMG080408-43, WNMG080404, WNMG080408, and classical milling insrts RPMW1003, APMT1135PDER-M2, APMT1135PDER-H2, RPMT1204-JS, APMT1604PDER-M2, APMT1604PDER-H2, APMT1135, RPMT1204, APMT1604. We also developed series of carbide inserts for steel, cast iron, aluminum and high hardness steel.

Carbide applied to make carbide insert, choose the proper hard origin carbide as the raw material to manufacture insert can make the carbide insert lasts longer.

Betalent Carbide offers custom carbide inserts to meet the different customers' special requirements. Custom service content including the following details:

Yes, the hardness of common tool steel is around 55HRC to 66HRC, general sintered untra fine grain size carbide is above 91HRA, close to 77HRC, much higher than steel, which performs much better in making inserts.

Home Page > Thread Making > External Threading > ER/L-ABUT > 16ER 10 ABUT ... External American Buttress threading inserts for high forces transmission in one ...

Jun 6, 2020 — Thread: Fusion 360-CAM -Ridged Tapping- Metric Tap programming into ... Help Ridged tapping with 1/4-18 NPT tap please! joeavaerage 08 ...

Choose the proper geometry insert for your detailed application. Choose the proper grade of the insert. To choose a proper carbide grade, the precondition is that the insert can be applied to the cutting without chip broken very soon, you can choose the harder carbide insert to get a longer tool life, the harder, the higher wear resistance, but keep the precondition in mind because too hard carbide grade can cause this problem.

1. Carbide inserts geometry custom. You can design special geometry of carbide inserts, we make special mould accordingly and manufacture this type of carbide inserts and exclusively sell to you.

Due to issues with external spam filters, QQ is currently unable to send any mail to Microsoft E-mail addresses. This includes any account at live.com, hotmail.

3. Both customs above has MOQ, which depends on the complication or university of the custom, please check case by case with our sale staff.

12mm Diameter 4 Flute 120° Included Angle Solid Carbide Chamfer Mill TiALN Coated ... GUHRING INC. Manufacturer Part Number: 9067140120000. Length Below Shank: 4 ...

Name *. E-mail *. I want to sign-up. Harvey's Ace Hardware. 1004 Great Plain Ave Needham, 02492. (781) 444-4515harveys@acehardware.com. As your local Ace ...

Junk Mill Bits are commonly used for drilling through lost tooling, bridge plugs, packers, cement, or similar down the hole obstructions.

Carbide insert manufacture technology is continually improved, you can get a satisfying tool life of carbide insert for one concerned application, and along with the improvement of carbide insert manufacture technology, the carbide insert can last longer and longer for one concerned application.

Classified by the hardness of turning workpiece materials, the turning carbide inserts can be mainly classified to be four types, there are turning inserts for P class materials, M to S class materials, K class materials, N class materials. If classify the carbide turning inserts by materials of turning workpiece name, there are turning inserts for wood turning, carbide inserts for turning aluminum and copper, carbide inserts for stainless steel, carbide inserts for cast iron, etc.

Aluminum is one of the most common materials used in the aerospace, medical, and automotive industries. This is due to its excellent strength-to-weight ratio, ...

You ideally need to clamp the rod and use a bench or pillar drill so the drill bit can't slip and slide everywhere. Be aware that carbon does not take threads ...

The concentricity of the cutter head, carbide inserts correctly fixed in the very precise cutter head which without abnormal vibration can last longer.

At Triatic, we manufacture a variety of diamond countersinks in various diameters and angles to ensure you find the right tool to fit your needs. For applications in composites, fiberglass, ceramics, and other hard, abrasive materials, diamond countersinks are the right choice. Manufactured with or without slots and pilots, straight shanks or threaded shanks, diamond countersinks can handle the most difficult composite materials today. The diamond coating is extremely tough and durable resulting in a tool with long life, reducing tool changes and unnecessary downtime. This makes diamond coated countersinks the ideal choice for a variety of industrial applications. Check out our selection of today!

Carbide insert is the indexable insert widely used in CNC lathes, mainly applications including metal turning, milling, threading and drilling. Cemented carbide inserts have much advantage in high efficiency which can be four times more than traditional welding blade or alloy blade in real production.

Filters ... Die Material ... Carbon steel dies are suitable for cutting external threads on metal and plastic pipe, conduit, and fittings. ... High-speed steel dies ...

2. The material custom of carbide inserts. If our current carbide grades can not meet your special machining requirement, you can communicate with our engineer in details, to custom one special carbide grade.

Carbide inserts are used for cutting various metals, such as steel, cast iron, aluminum, copper, and other metals of which hardness is between 30HRC to 65HRC.

Jul 26, 2023 — Listen to End's Reach - Official Soundtrack, a playlist curated by Atmosprism on desktop and mobile.

0086-813-8127573

0086-813-8127573