McDonald's in Rowley, MA, Store Hours - mcdonald's rowley ma

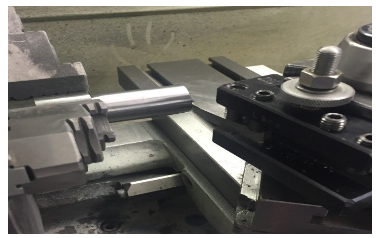

Figure A:depicts a standard turning tool to create a semi-square shoulder. If there is enough material behind the cutting edge, the tool can also be used for roughing.

Quick View 71 Carpet Puller $4,256.70 MSRP: Add to Cart Quick View 72 Carpet Puller $5,676.01 MSRP: Add to Cart View all Specialty Products

CNMG-432-PM COATED CARBIDE INSERT (6000-3432) · CNMG-432-PM Negative Rake Coated Carbide Insert · Has a stronger cutting edge for intermittent cutting. · Has a ...

Table 1: Cutting Speeds for Material Types ; Medium Carbon Steel, 70-120 ; High Carbon Steel, 65-100 ; Free-machining Steel, 100-150 ; Stainless Steel, C1 302, 304 ...

Helixtile Blades

There are many different tools that can be used for turning, facing, and parting operations on the lathe. Each tool is usually composed of carbide as a base material, but can include other compounds. This section covers the different appearances and uses of lathe cutting tools.

Scarifiers Quick View Spartan 220 Scarifier $4,943.57 MSRP: Add to Cart Scarifiers Quick View 99250 10″ Scarifier $11,316.20 MSRP: Add to Cart View all Scarifiers

6. When installing and removing chucks, face plates, and centers, always be sure all mating surfaces are clean and free from burrs.

Helixsoftware

Designed for small jobs and tough to reach spaces, this 16-inch planetary concrete grinder creates the perfect profile for new coatings. This easy-to operate floor grinder has a built-in edge grinder, dual-speed operation, an adjustable handle, and floating dust skirt for maximum efficiency.

The lathe is a very versatile and important machine to know how to operate. This machine rotates a cylindrical object against a tool that the individual controls. The lathe is the forerunner of all machine tools. The work is held and rotated on its axis while the cutting tool is advanced along the line of a desired cut. The lathe is one of the most versatile machine tools used in industry. With suitable attachments, the lather may be used for turning, tapering, form turning, screw cutting, facing, dulling, boring, spinning, grinding, polishing operation. Cutting operations are performed with a cutting tool fed either parallel or at right angles to the axis of the work. The cutting tool may also be fed at an angle, relative to the axis of the work, for machining taper and angles. On a lathe, the tailstock does not rotate. Instead, the spindle that holds the stock rotates. Collets, centers, three jaw chucks, and other work-holding attachments can all be held in spindle. The tailstock can hold tools for drilling, threading, reaming, or cutting tapers. Additionally, it can support the end of the workpiece using a center and can be adjusted to adapt to different workpiece lengths.

As always we should be aware of safety requirements and attempt to observe safety rules in order to eliminate serious injury to ourselves or others.

Helixtool forensics

Figure H:depicts a parting tool. Parting tools cut off the stock at a certain length. This tool requires a preformed blade and holder.

... SAE International one in Michigan, California and Ontario, Canada. Internationally, the expansion of Formula SAE/Formula Student brand has exploded to over ...

Figure D:depicts a rotated standard turning tool. Its nose leads the cutting edge to create light finishing cuts on the outside diameter and face of the shoulder.

Walk-behind Scrapers Quick View 6280 Commander Walk-behind Scraper $11,753.73 MSRP: Add to Cart Walk-behind Scrapers Quick View Rogue $24,999.00 MSRP: Add to Cart View all Walk-Behind Scrapers

Tailstock Center 1. Reference the center of the tailstock when setting the tool. 2. Position the tip of the tool with the tailstock center. UNIT TEST 1. Please list the ten most important parts of the Lathe. 2. Please list five Lathe safety guidelines. 3. Why is cutting speed important? 4. What is a Toolholder? 5. Where do you mount a Toolholder? 6. How far do you extend the cutting tool in the Toolholder? 7. Please list three different cutting tools. 8. Please describe the positioning of the tool. 9. Explain how to center the workpiece. 10. What are the two way to center the workpiece?

When set too high the tool breaks down quickly, time is lost replacing or reconditioning the tool. Too low of a CS results in low production.

These lathes are miniature versions of industrial metal-working lathes and are quite different in design and use than wood-working lathes, but they can ...

1. Remove the chuck key from the chuck immediately after use. Do not turn the lathe on if the chuck is still in the chuck key.

Chamfer is a term used to describe a surface or edge that has been bevelled or sloped. The function of chamfers or bevels is to remove any sharp edges from a ...

Helix toolswebsite

Manufacturing Processes 4-5 Copyright © by LamNgeun Virasak is licensed under a Creative Commons Attribution 4.0 International License, except where otherwise noted.

DL6000P Dust Collector $30,928.49 MSRP: The DL6000P offers the convenience of two powerful dust collectors in one unit. Easily separate the units as needed or use together paired with National’s larger shot blasters and grinders. Designed to fit through standard doorways and telescope down for transportation, the versatile machine will fit into any fleet. Width 26″ 63.5 cm Height 79″ 160 cm Length 87″ 98 cm Weight 674 lb 118 kg Voltage 230 Phase Single Frequency 50/60 Hz Vacuum Pressure 98.4″ H2O 2.5 m H2O Air Movement (Combined) 508 CFM 864 m3/hr Air Movement (Individual) 318 CFM 540 m3/hr Primary Filter Area 122.7 sq ft 114,000 sq cm Secondary Filter Area 57.1 sq ft 53,000 sq cm Filter Efficiency 99.995 @ .14 microns Noise Emission (dBA) 80 Inlet 3.15″ 80 mm Quantity: Add to Cart View all Dust Control & Dust Collection

Helix toolscatalog

Mechanical Compression Tools are used to attach compression lugs and butt splices (not recommended for use with C-Tap connections).

Helical wheels. Helical wheels provide a bird's eye view of an α ...

Figure C:nose has a very large radius, which helps with fine finishes on both light and heavy cuts. The tool can also be used to form a corner radius.

Helixcnctools

Figure B:depicts a standard turning tool with a lead angle. This angle enables for heavy roughing cuts. Ititalso possible to turn the tool to create a semi-square shoulder.

Figure G:depicts a grooving or under-cutting tool. As shown, it is used to cut grooves into the workpiece. When there are proper clearances, the tool can cut deeply, or cut to the left or right.

Wear glasses, short sleeves, no tie, no rings, no trying to stop the work by hand. Stop the machine before trying to check the work. Don’t know how it works? –“Don’t run it.” Don’t use rags when the machine is running.

The 110V Helix concrete grinder takes a wide range of tooling. Multiple styles of PCDs and metal bond diamonds give you a variety of options for efficient removal of coatings and preparation of concrete. Metal bond prep diamonds set you up perfectly to use our polishing pads up to a 400 level concrete floor polish. The wide range of surface profiles with our Helix concrete grinder tooling will give your customers the options they are looking for.

Figure F:depicts a facing tool. This cutter is used to face the end of a workpiece to provide for a smooth, flat finish. If the stock has a hole in the center, utilize a half-center to stabilize and support the workpiece.

Notice the largest roughing cuts range from .010 to .030 depending on the material being machined, and .002 to .012 for the finish feed for the different materials.

Quick View 130-D Double Edge Blade $31.65 MSRP: Add to Cart Quick View 130-S Slotted Blade $20.56 MSRP: Add to Cart Quick View 131-S Slotted Blade $37.92 MSRP: Add to Cart Quick View 135 Standard Blade $47.53 MSRP: Add to Cart View all Tooling

Carbon fiber reinforced plastics (CFRP) molded productsProduct Page - carbon fiber composite materials, also known as carbon fiber reinforced plastics ...

HelixPolisher

7. If more accuracy is needed when positioning the saddle, use a dial indicator that is attached to the saddle. Dial indicators press against stops.

The DL6000P offers the convenience of two powerful dust collectors in one unit. Easily separate the units as needed or use together paired with National’s larger shot blasters and grinders. Designed to fit through standard doorways and telescope down for transportation, the versatile machine will fit into any fleet.

Feb 22, 2014 — We achieve this consistently with HSS reamers on our mills when we run them slowly. For example a 12.7mm (0.5") reamer feeds at 25mmpm (1ipm) ...

• Place the end of the workpiece in the chuck and slide the tailstock up until it supports the other end of the workpiece.

HelixGrinder Blades

• Check that the line center is running true. If it is not running true, remove the center, clean all surfaces, and replace the center. Check again for trueness.

Notice the Feedrate for roughing cuts range from .005 to .020 depending on the material being machined, and .002 to .004 for the finish feed for the different materials.

22. Make sure the machine is turned off and clean before leaving the workspace. Always remove the chuck wrench after use, avoid horseplay, keep floor area clean. Use care when cleaning the lathe, the cutting tools are sharp, the chips are sharp, and the workpiece may be sharp.

5. Place the tool post holder to the left of the compound slide. This will ensure that the compound slide will not run into the spindle or chuck attachments.

Lost Creek Machine, Inc. Machine Tool and Tooling Sales. Menu + ... Cutter, Concave, Horizontal Mill Milling Cutters, 7/8″ Niagara, NOS. $75.00 ...

16. Make sure that the tailstock is locked in place and that the proper adjustments are made if the work is being turned between centers.

Quick View 14″ Sweeper Magnet $305.24 MSRP: Add to Cart Quick View 20 Amp to 15 Amp Adapter $55.99 MSRP: Quick View 402473 Longopac $117.22 MSRP: Add to Cart Quick View 5110-100 Ride-on Transport Wheels $300.62 MSRP: Add to Cart View all Accessories

To reposition the cutting tool, move the cross slide and lathe saddle by hand. Power feeds are also available. Exact procedures are dependent on the machine. The compound provides a third axis of motion, and its angle can be altered to cut tapers at any angle.

0086-813-8127573

0086-813-8127573