Mechanics and Dynamics of the Circular Milling Process - circle milling

Lathe machineoperations

Carbon fibers are a type of high-performance fiber available for civil engineering application. It is also called graphite fiber or carbon graphite, carbon fiber consists of very thin strands of the element carbon. Carbon fibers have high tensile strength and are very strong for their size. In fact, carbon fiber might be the strongest material. Carbon fibers have high elastic modulus and fatigue strength than those of glass fibers. Considering service life, studies suggests that carbon fiber reinforced polymers have more potential than agamid and glass fibers. They also are highly chemically resistant and have high temperature tolerance with low thermal expansion and corrosion resistance.

Types oflathe machine

6. When installing and removing chucks, face plates, and centers, always be sure all mating surfaces are clean and free from burrs.

It has more applications in civil engineering, military, sporting goods, in medical, in automobile industry, etc. so use of carbon fiber in construction is always effective and provides high strength to the structure.

Carbon fiber offers several advantages over other materials in the medical field, including the fact that it is radiolucent transparent to X-rays and shows as black on X-ray images. It is used widely in imaging equipment structures to support limbs being X-rayed or treated with radiation. The use of carbon fiber to strengthen of damaged cruciate ligaments in the knee is being researched, but probably the most well known medical use is that of prosthetics artificial limbs.

As always we should be aware of safety requirements and attempt to observe safety rules in order to eliminate serious injury to ourselves or others.

This feature can be useful and be a nuisance. In Boat building it has to be taken into account just as Aluminium conductivity comes into play. Carbon fiber conductivity can facilitate Galvanic Corrosion in fittings. Careful installation can reduce this problem. Carbon Fiber dust can accumulate in a shop and cause sparks or short circuits in electrical appliances and equipment.

Manufacturing Processes 4-5 Copyright © by LamNgeun Virasak is licensed under a Creative Commons Attribution 4.0 International License, except where otherwise noted.

The 20th century saw a roller coaster ride in the demand for carbon fiber. Threats to peace increased the demand for carbon fiber for defence purposes mid- century. A downturn in defence needs result in a reduction in production of carbon fiber toward the close of the century. By the beginning of the 21st century, new applications and new markets sent the production of carbon fibers on an upswing. Despite a downturn in 2007-2008, worldwide demand increased to

Lathe machineuses

approximately 40,000 metric tons in 2010. Carbon fibers have revolutionized the technology of materials. It is no wonder that the National Academy of Engineering voted carbon fibers one of the 20 top engineering achievements of the 20th century and the American Chemical Society named the development of high performance carbon fibers a National Historic Chemical Landmark in September 2003.

MDPI – Open Access Publishing, Issue: Materials/ December-2009, Title: Fabrication and Properties of Carbon Fibers, Author: Xiaosong Huang

When set too high the tool breaks down quickly, time is lost replacing or reconditioning the tool. Too low of a CS results in low production.

1. Remove the chuck key from the chuck immediately after use. Do not turn the lathe on if the chuck is still in the chuck key.

Carbon fiber has gone to the moon on spacecraft, but it is also used widely in aircraft components and structures, where its superior strength to weight ratio far exceeds that of any metal. 30% of all carbon fiber is used in the aerospace industry. From helicopters to gliders, fighter jets to micro lights, carbon fiber is playing its part, increasing range and simplifying maintenance.

Figure D:depicts a rotated standard turning tool. Its nose leads the cutting edge to create light finishing cuts on the outside diameter and face of the shoulder.

Lathe Machineprice

Download Full-Text PDF Cite this Publication Prince M Patel, Harsh N Patel, Shyam D Kotecha, 2013, Properties of Carbon Fiber and its Applications, INTERNATIONAL JOURNAL OF ENGINEERING RESEARCH & TECHNOLOGY (IJERT) Volume 02, Issue 11 (November 2013),

• Place the end of the workpiece in the chuck and slide the tailstock up until it supports the other end of the workpiece.

Dr. Jackie Rehkopf, Automotive Carbon Fiber Composites: From Evolution to Implementation, ISBN of 978-0-7680-3495-0, Published by: SAE International (29th November 2011)

Figure G:depicts a grooving or under-cutting tool. As shown, it is used to cut grooves into the workpiece. When there are proper clearances, the tool can cut deeply, or cut to the left or right.

Resistance to Fatigue in Carbon Fiber Composites is good. However when carbon fiber fails it usually fails catastrophically without much to announce its imminent break. Damage in tensile fatigue is seen as reduction in stiffness with larger numbers of stress cycles, (unless the temperature is high).

Figure A:depicts a standard turning tool to create a semi-square shoulder. If there is enough material behind the cutting edge, the tool can also be used for roughing.

5 uses oflathe machine

Thermal conductivity is the quantity of heat transmitted through a unit thickness, in a direction normal to a surface of unit area, because of a unit temperature gradient, under steady conditions. In other words its a measure of how easily heat flows through a material

There are many different tools that can be used for turning, facing, and parting operations on the lathe. Each tool is usually composed of carbide as a base material, but can include other compounds. This section covers the different appearances and uses of lathe cutting tools.

Notice the largest roughing cuts range from .010 to .030 depending on the material being machined, and .002 to .012 for the finish feed for the different materials.

Carbon fibre plates are thin, strong and flexible, they can be designed and installed to provide a cost effective solution which does not detract visually from the original design of the structure.

Each fiber is 5-10 microns in diameter. To give a sense of how small that is, one micron (um) is 0.000039 inches. One strand of spider web silk is usually between 3-8 microns. Carbon fibers are twice as stiff as steel and five times as strong as steel, (per unit of weight). . The most important factors determining the physical properties of carbon fiber are degree of carbonization (carbon content, usually more than 92% by weight) and orientation of the layered carbon planes (the ribbons).

16. Make sure that the tailstock is locked in place and that the proper adjustments are made if the work is being turned between centers.

Wear glasses, short sleeves, no tie, no rings, no trying to stop the work by hand. Stop the machine before trying to check the work. Don’t know how it works? –“Don’t run it.” Don’t use rags when the machine is running.

5. Place the tool post holder to the left of the compound slide. This will ensure that the compound slide will not run into the spindle or chuck attachments.

Over the ages as we have evolved, so has our engineering and researching skill sets. Even today, we are constantly innovating, researching and developing technology in pursuit of a sustainable future. Throughout this evolution, researches and engineers have found themselves in constant search for new and better materials to optimally manage the performance cost trade-off in the construction sector. Many new raw materials have been discovered and many ground- breaking composite have been developed, of which not all but some have proved to be a phenomenal success. Carbon fiber is one of these materials, which is usually used in combination with other materials to form a composite. The properties of carbon fiber, such as high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance and low thermal expansion makes them one of the most popular material in civil engineering possessing strength up to five times that of steel and being one- third its weight, we might as well call it the superhero of the material world.

Tensile strength or ultimate strength is the maximum stress that a material can withstand while being stretched or pulled before necking, or failing. Necking is when the sample cross-section starts to significantly contract. If you take a strip of plastic bag, it will stretch and at one point will start getting narrow. This is necking. It is measured i Force per Unit area. Brittle materials such as carbon fiber do not always fail at the same stress level because of internal flaws. They fail at small strains. Testing involves taking a sample with a fixed cross-section area, and then pulling it gradually increasing the force until the sample changes shape or breaks. Fibers, such as carbon fibers, being only 2/10,000th of an inch in diameter, are made into composites of appropriate shapes in order to test. Units are MPa this table is offered as a comparison only since there are a great number of variables.

Note that strength and rigidity are different properties, strength is resistance to breaking, and rigidity is resistance to bending or stretching.

Rigidity or stiffness of a material is measured by its Young Modulus and measures how much a material deflects under stress. Carbon fiber reinforced plastic is over 4 times stiffer than Glass reinforced plastic, almost 20 times more than pine, 2.5 times greater than aluminium.

Lathe machinePDF

is an example. Because carbon fiber is also chemically very inert, it can be used where there is fire combined with corrosive agents. Carbon Fiber Blanket used as welding protection.

Depending upon the manufacturing process and the precursor material, carbon fiber can be quite soft and can be made into or more often integrated into protective clothing for fire fighting. Nickel coated fiber

Figure C:nose has a very large radius, which helps with fine finishes on both light and heavy cuts. The tool can also be used to form a corner radius.

Notice the Feedrate for roughing cuts range from .005 to .020 depending on the material being machined, and .002 to .004 for the finish feed for the different materials.

To reposition the cutting tool, move the cross slide and lathe saddle by hand. Power feeds are also available. Exact procedures are dependent on the machine. The compound provides a third axis of motion, and its angle can be altered to cut tapers at any angle.

Figure H:depicts a parting tool. Parting tools cut off the stock at a certain length. This tool requires a preformed blade and holder.

This is a measure of how much a material expands and contracts when the temperature goes up or down. Units are in Inch / inch degree F, as in other tables, the units are not as important as the comparison.

Low Coefficient of Thermal expansion makes carbon fiber suitable for applications where small movements can be critical. Telescope and other optical machinery is one such application.

Lathe machinediagram

The applications in the military are very wide ranging from planes and missiles to protective helmets, providing strengthening and weight reduction across all military equipment. A new military application is announced almost every day. Perhaps the latest and most exotic military application is for small flapping wings on miniaturized flying drones, used for surveillance missions. Of course, we dont know about all military applications some carbon fiber uses will always remain part of black ops in more ways than one.

Several structural engineering applications utilize carbon fiber reinforced polymer because of its potential construction benefits and cost effectiveness. The usual applications include strengthening structures made with concrete, steel, timber, masonry, and cast iron; Retrofitting to increasing the load capacity of old structures like bridges; to enhance shear strength and for flexure in reinforced concrete structures. Other

The lathe is a very versatile and important machine to know how to operate. This machine rotates a cylindrical object against a tool that the individual controls. The lathe is the forerunner of all machine tools. The work is held and rotated on its axis while the cutting tool is advanced along the line of a desired cut. The lathe is one of the most versatile machine tools used in industry. With suitable attachments, the lather may be used for turning, tapering, form turning, screw cutting, facing, dulling, boring, spinning, grinding, polishing operation. Cutting operations are performed with a cutting tool fed either parallel or at right angles to the axis of the work. The cutting tool may also be fed at an angle, relative to the axis of the work, for machining taper and angles. On a lathe, the tailstock does not rotate. Instead, the spindle that holds the stock rotates. Collets, centers, three jaw chucks, and other work-holding attachments can all be held in spindle. The tailstock can hold tools for drilling, threading, reaming, or cutting tapers. Additionally, it can support the end of the workpiece using a center and can be adjusted to adapt to different workpiece lengths.

Figure B:depicts a standard turning tool with a lead angle. This angle enables for heavy roughing cuts. Ititalso possible to turn the tool to create a semi-square shoulder.

7. If more accuracy is needed when positioning the saddle, use a dial indicator that is attached to the saddle. Dial indicators press against stops.

Strength of a material is the force per unit area at failure, divided by its density. Any material that is strong and light has a favourable Strength/weight ratio. Materials such as Aluminium, titanium, magnesium, Carbon and glass fiber, high strength steel alloys all have good strength to weight ratios. It is not surprising that Balsa wood comes in with a high strength to weight ratio. The following figures are offered for comparison only and will vary depending on composition, alloy, type of spider, density of wood etc. The units are kN.m/kg.

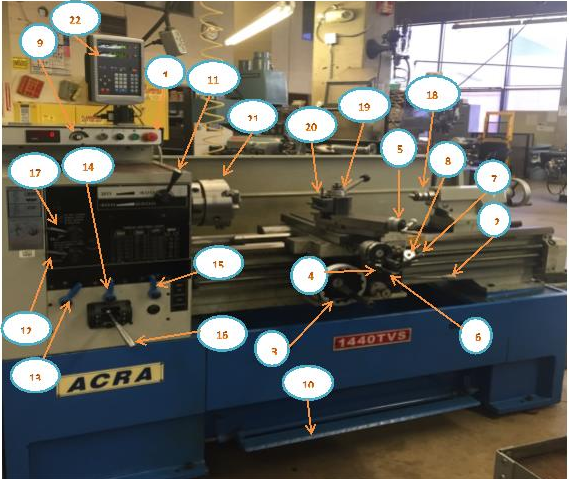

Lathe machineparts

Figure F:depicts a facing tool. This cutter is used to face the end of a workpiece to provide for a smooth, flat finish. If the stock has a hole in the center, utilize a half-center to stabilize and support the workpiece.

22. Make sure the machine is turned off and clean before leaving the workspace. Always remove the chuck wrench after use, avoid horseplay, keep floor area clean. Use care when cleaning the lathe, the cutting tools are sharp, the chips are sharp, and the workpiece may be sharp.

• Check that the line center is running true. If it is not running true, remove the center, clean all surfaces, and replace the center. Check again for trueness.

It has high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance and one of the most popular materials in civil engineering.

As costs come down, carbon fiber is being more widely adopted in automobiles. Supercar bodies are built now, but its wider use is likely to be in internal components such as instrument housings and seat frames.

Carbon fiber-reinforced composite materials are used to make aircraft and spacecraft parts, racing car bodies, golf club shafts, bicycle frames, fishing rods, automobile springs, sailboat masts, and many other components where light weight and high strength are needed. Carbon fibers high strength, light weight and resistance to corrosion make it an ideal reinforcing material.

Tailstock Center 1. Reference the center of the tailstock when setting the tool. 2. Position the tip of the tool with the tailstock center. UNIT TEST 1. Please list the ten most important parts of the Lathe. 2. Please list five Lathe safety guidelines. 3. Why is cutting speed important? 4. What is a Toolholder? 5. Where do you mount a Toolholder? 6. How far do you extend the cutting tool in the Toolholder? 7. Please list three different cutting tools. 8. Please describe the positioning of the tool. 9. Explain how to center the workpiece. 10. What are the two way to center the workpiece?

Although carbon fiber themselves do not deteriorate, Epoxy is sensitive to sunlight and needs to be protected. Other matrices (whatever the carbon fiber is imbedded in) might also be reactive.

0086-813-8127573

0086-813-8127573