Medicare Benefits Schedule - Item 30520 - 30520

Discover the latest in high-quality user-generated content, including exclusive images and videos you can only find here.

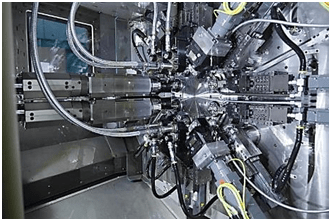

High Performance CNC Drilling Machines · iTECH 2460 Vertical CNC Drilling Machine. IN STOCK.

by RA Mali · 2021 · Cited by 69 — The advent of CNC machines resulted in the reduction of machining complexity through efficient programming and increased productivity. The free-form surface ...

After performing the calculation, the optimal lathe speed would be approximately 797 RPM. By accurately calculating the optimal lathe speed, you can achieve ...

The depth of cut parameter focuses on the tertiary cutting motion of the tool as the tool is pushed deeper into the workpiece to the specified depth. This parameter is measured as thousandths of an inch or thousandths of millimeters. The depth of cut will usually vary between 0.1 to 1.0 mm.

Sand casting is a metal forming process in which a mold is first formed from a three-dimensional pattern of sand, and molten metal is poured into the mold cavity for solidification.

Browse 4,216 authentic deep hole stock photos, high-res images, and pictures, or explore additional in deep hole or deep hole earth stock images to find the right photo at the right size and resolution for your project.

CNC lathes minimize these issues with preprogrammed parameters that focus on the speed, feed, and depth of cut performed on the part.

Explore the latest in news, sports, and entertainment coverage, featuring exclusive videos that can’t be found anywhere else.

Epic Tool specializes in the design and manufacture of solid carbide cutting tools, high performance-end mills, drills, reamers and custom carbide tools for ...

Streamline your workflow with our best-in-class digital asset management system. Organize, control, distribute and measure all of your digital content.

Check out the latest in entertainment, from the red carpet to center stage, featuring celebrity coverage you can only get from us.

Browse millions of royalty-free images and photos, available in a variety of formats and styles, including exclusive visuals you won't find anywhere else.

Search the latest news photos & coverage of world events with high-quality images and video content, available in 4K & HD formats.

Turning machines used to produce hydraulic parts provide immense benefits. These machines can produce hydraulic parts such as pistons and cylinder assemblies quickly while being cost-effective. The CNC lathe machine works by removing materials from the part at specific speeds as the equipment rotates the workpiece until reaching a specific depth. When creating the workpiece with precision machining processes, common issues such as friction, chip formation, heat generation or conductivity to the metal may occur. These problems may negatively impact the metal’s grain structure to cause damage, creating an inaccurate workpiece.

Impro is an integrated one-stop solution providers. In addition to our primary manufacturing process technologies, we have other in-house casting processes such as permanent mold casting and shell mold casting to satisfy aerospace customers’ need for precision aluminum castings. At Impro manufacturing facilities, our comprehensive heat treatment and laboratory services can ensure products are processed timely in accordance with exact specifications and customer requirements.

20211020 — Strongest Metals Used in Metals Fabrication · 1. Titanium. This naturally occurring metal possesses a high tensile strength given its less dense ...

Experience Generative AI by Getty Images: a solution that pairs Getty Images' vast content and data with the latest AI technology.

When figuring out these two parameters to preprogram into the CNC lathe, the hardness of the metal and how rigid the workpiece is must be taken into account. If using too high of a cutting speed or feed for a soft metal, the tool may end up removing too much in one pass. Cutting a hard metal at too low of a speed or feed rate may not provide the desired surface finish. One key aspect to keep in mind is that the tool’s speed must increase when the hardness and strength of the metal increases.

Check out millions of royalty‑free videos, clips, and footage available in 4K and HD, including exclusive visual content you won't find anywhere else.

Explore the latest in news, sports, and entertainment coverage, featuring exclusive images that can’t be found anywhere else.

In this article we will discuss what are the different types of end mills, their application, pros and cons and finally discuss which end mill should you ...

10pcs 1/8 Shank Carbide Burr Set Burrs For Aluminum Die Grinder Bit Pack. Add ... Metal Drill Bits · Carbide Burr Bit Set · All Drill Bits · Power Drill ...

This tungsten burr set is best for stock removal on cast iron, steel iron, aluminum, copper, and other hard materials like wood and stone.

Explore millions of royalty‑free vectors in a variety of formats and styles, including exclusives you can only find on Getty Images.

Explore collections of diverse images and videos, crafted through strategic brand partnerships and customer needs that ensure genuine visual storytelling for every project.

Significant improvements to the workpiece can be made with the use of a CNC lathe machine. A CNC lathe can make a rougher finish by having the preprogrammed machine lower the depth of the cut parameter. The machine may also remove more materials and speed up the production process with an increase to the depth of the cut parameter.

Discover millions of royalty‑free, exclusive illustrations in a variety of styles, from conceptual to contemporary, and more.

Global trade policies, supply chain issues, transportation and shipping capacity shortage are among many factors that impact customers in different regions around the world. It can impede customer demand, slow down supply chain capabilities and raise costs. Localized production and near-sourcing are the growing trends. To offset the hurdles and provide more vertically integrated solutions to North American customers, Impro’s high precision machining and casting operations are expanding into Mexico.

These three parameters focus on how the hydraulic part is cut. Cutting speed represents how fast the metal is removed from the workpiece. Cutting feed focuses on how far the cutting spindle travels across the metal part during one full rotation of the tool. As the cutting tool moves into the metal part, the distance that it moves is the depth of cut. These three parameters ensure accuracy of the finished workpiece and the surface finish.

Determining the cutting speed for the precision machine is based on the peripheral speed of the workpiece when it is fed past the rotating cutting tool. This measurement is shown as feet per minute or meters per minute based on the cutting speed velocity. The cutting feed rate and the cutting speed helps to determine the power requirements of the tool to ensure it is moving at a rate that is appropriately defined based on how much material is cut away in one rotational pass.

From the sidelines to the pitch, check out the latest and greatest images and videos from must-see, global sports events.

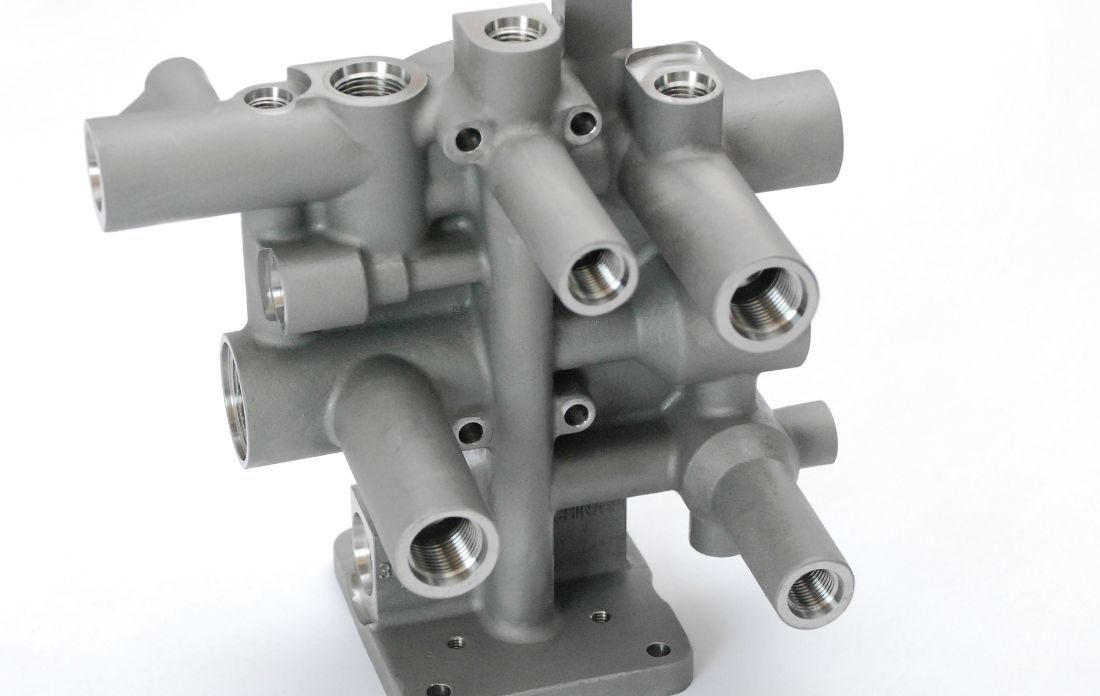

Investment casting is a metal forming process that generally involves using a wax pattern surrounded by a ceramic shell to form a ceramic mold. Once the ceramic shell is dry, the wax is melted out, and the ceramic mold is formed.

Hydraulic machines are used on industrial, commercial, and public applications to perform a range of tasks. They are found in heavy equipment, food processing, aircraft, and other equipment. To create hydraulic components, precision machine tools are often used. These consist of machine tools such as CNC lathes.

HSS Dove Tail Cutter ... Dovetail cutters are specialized tools for cutting a dovetail angled grooves into a workpiece and are used for fitting or joining parts.

Surface treatment generally refers to a process to alter an object’s surface to enhance its appearance or functional properties. At Impro, surface treatment refers to electroplating, one of the most widely-used surface treatment techniques that provide broad coverage of coating metals and high cost-efficiency.

Precision machining is a process to produce accurate components with high tolerances and excellent surface quality by removing materials from a workpiece. It involves a combination of several or all of the turning, milling, drilling, gear cutting, honing, grinding processes, and other steps.

Our manufacturing capabilities cover the entire casting component production process, from tooling design and manufacturing, casting, secondary machining, heat treatment, surface treatment to finishing, enabling us to offer ready-to-use products and services to customers. overview:We offer comprehensive one-stop solutions that cover the precision component manufacture value chain throughout the entire product life cycle.

Access the best of Getty Images with our simple subscription plan. Millions of high-quality images, video, and music options are waiting for you.

Jun 7, 2024 — business unit as Atlantic Automation Co. and expand operations to North Carolina. This move leverages HSM's capabilities at its Hickory, North ...

Explore Getty Images Music, powered by Triple Scoop Music’s library of original audio content, which includes music, sound effects, and royalty-free tracks.

Tap into Getty Images' global scale, data-driven insights, and network of more than 340,000 creators to create content exclusively for your brand.

The parameter impacts the performance and efficiency of the precision machining process. To select the right depth of cut, the following factors are taken into consideration:

0086-813-8127573

0086-813-8127573