Melin Tool Company - Premium End Mills, Drills & Cutting Tools - end mills near me

915MHz MPCVD Diamond Machine and its multi-crystal effective growth, the maximum area can reach 8 inches, the maximum effective growth area of single crystal can reach 5 inches. This equipment is mainly used for the production of large-size polycrystalline diamond films, the growth of long single crystal diamonds, the low-temperature growth of high-quality graphene, and other materials that require energy provided by microwave plasma for growth.

PVDvsCVDadvantagesanddisadvantages

Looking for high-quality laboratory equipment for PVD and CVD processes? Look no further than KINTEK! With our advanced technology and expertise, we provide the best solutions for your deposition needs. Whether you need physical force-based PVD or chemical reaction-based CVD, we have the equipment to meet your requirements. Contact us today and take your research to the next level with KINTEK's cutting-edge laboratory equipment.

CVD diamond wire drawing die blanks: superior hardness, abrasion resistance, and applicability in wire drawing various materials. Ideal for abrasive wear machining applications like graphite processing.

PVD and CVD are both thin film coating processes, but they differ in terms of the processes they employ and the nature of the deposition. PVD relies on physical forces and does not involve chemical reactions. CVD utilizes chemical processes for thin film deposition. PVD deposition is line-of-sight, while CVD deposition is diffuse and multidirectional, resulting in differences in coating results on uneven surfaces.

The nano-diamond composite coating drawing die uses cemented carbide (WC-Co) as the substrate, and uses the chemical vapor phase method ( CVD method for short ) to coat the conventional diamond and nano-diamond composite coating on the surface of the inner hole of the mold.

CVD (Chemical Vapor Deposition): CVD uses chemical processes to produce a thin film. During the CVD process, one or more volatile precursors are introduced into a reaction chamber along with the substrate. The precursors react or decompose on the substrate surface, forming a thin layer of coating. Chemical reactions occur in CVD.

Difference between pvd and cvdchemistry

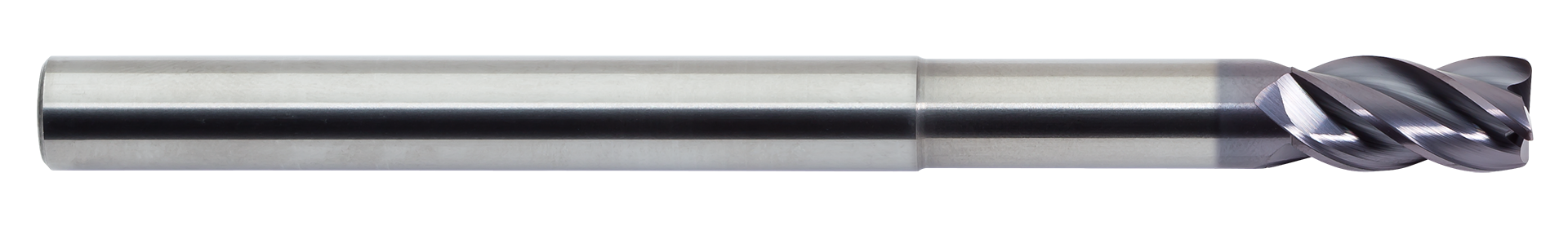

CVD Diamond Cutting Tools: Superior Wear Resistance, Low Friction, High Thermal Conductivity for Non-Ferrous Materials, Ceramics, Composites Machining

Disadvantages ofCVD

Understanding the difference between PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) is crucial for anyone involved in thin film coating processes.

We use cookies to improve your experience, to remember log in details, and to optimize site functionality and deliver content tailored to your interests. Our Privacy Policy.

Difference between pvd and cvdcar

Introducing our inclined rotary PECVD furnace for precise thin film deposition. Enjoy automatic matching source, PID programmable temperature control, and high accuracy MFC mass flowmeter control. Built-in safety features for peace of mind.

CVD Diamond Coating: Superior Thermal Conductivity, Crystal Quality, and Adhesion for Cutting Tools, Friction, and Acoustic Applications

RF-PECVD is an acronym for "Radio Frequency Plasma-Enhanced Chemical Vapor Deposition." It deposits DLC (Diamond-like carbon film) on germanium and silicon substrates. It is utilized in the 3-12um infrared wavelength range.

Get high-quality diamond films with our Bell-jar Resonator MPCVD machine designed for lab and diamond growth. Discover how Microwave Plasma Chemical Vapor Deposition works for growing diamonds using carbon gas and plasma.

CVD boron-doped diamond: A versatile material enabling tailored electrical conductivity, optical transparency, and exceptional thermal properties for applications in electronics, optics, sensing, and quantum technologies.

PVD (Physical Vapor Deposition): PVD deposition involves the vaporization of solid physical particles into a plasma, which is then deposited onto the substrate. This is a line-of-sight deposition, meaning that the deposition occurs in a specific direction. As a result, PVD may have limitations in terms of thickness and uniformity of deposition on uneven surfaces.

PVDcoating

CVD (Chemical Vapor Deposition): CVD technology is capable of producing uniform thin coatings on uneven surfaces. The diffuse and multidirectional deposition allows for better coverage and conformity, even on complex shapes or the underside of the substrate.

CVD (Chemical Vapor Deposition): CVD deposition occurs in a flowing gaseous state. The precursors introduced into the reaction chamber undergo chemical reactions on the substrate surface, leading to the formation of a thin film. This type of deposition is diffuse and multidirectional, allowing for more uniform and conformal coatings on uneven surfaces.

Difference between pvd and cvdpdf

Get your exclusive CVD furnace with KT-CTF16 Customer Made Versatile Furnace. Customizable sliding, rotating, and tilting functions for precise reactions. Order now!

CVDvsPVDinserts

RF-PECVD is an acronym for "Radio Frequency Plasma-Enhanced Chemical Vapor Deposition." It deposits DLC (Diamond-like carbon film) on germanium and silicon substrates. It is utilized in the 3-12um infrared wavelength range.

Upgrade your coating process with PECVD coating equipment. Ideal for LED, power semiconductors, MEMS and more. Deposits high-quality solid films at low temps.

Difference between pvd and cvdcoating

Upgrade your coating process with PECVD coating equipment. Ideal for LED, power semiconductors, MEMS and more. Deposits high-quality solid films at low temps.

PVD (Physical Vapor Deposition): PVD uses physical forces to deposit a thin film onto a substrate. The process involves gasifying a pure source material through methods like evaporation, high-power electricity, or laser ablation. The gasified material then condenses on the substrate to create the desired layer. There are no chemical reactions involved in PVD.

PVD (Physical Vapor Deposition): PVD coatings may have limitations in coating the sides and back of the substrate. The line-of-sight nature of PVD deposition can result in uneven coverage on complex shapes or the underside of the substrate.

Learn about Cylindrical Resonator MPCVD Machine, the microwave plasma chemical vapor deposition method used for growing diamond gemstones and films in the jewelry and semi-conductor industries. Discover its cost-effective advantages over traditional HPHT methods.

0086-813-8127573

0086-813-8127573