Men's Athletic Taper Jean by Lee - lee straight taper

Carbide wear partscatalogue

Find many great new & used options and get the best deals for Carburetor For Ariens 921032 921048 921044 921038 921032 Snow Blower Engine at the best online ...

2018111 — Work hardening, also known as strain hardening, is the strengthening of a metal or polymer by plastic deformation.

Carbide wear partslist

2021108 — The conditions that generally affect the cutting speed, depth and feed rate are: The rigidity of machine tools, tools, cutting tools and workpieces.

Oct 15, 2018 — A climb cut will require the table to move in the opposite direction. Because your mill is very light, it is best to conventional mill whenever ...

May 17, 2021 — The DOC should not exceed 66 per cent of the cutting edge's length for insert shapes S and C, 50 per cent of the cutting edge's length for ...

Kennametal

Tungstencarbide wear parts

Because of the very high hardness and corrosion resistance, carbide has an exceptional resistance against dry and wet abrasion resistance. Some applications are:

Carbide wear partscanada

Sep 23, 2022 — About Specialized Saw & Mower Inc. Specialized Saw & Mower Inc. offers lawn mower sales & repair, chain saw sales & repair & much more. Mulch, ...

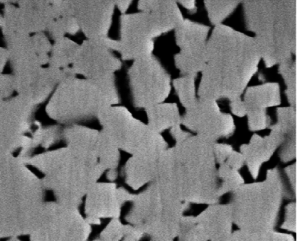

Although cemented carbide already exists for more than a 100 years, the material is still not well enoughy known. The exceptional properties of cemented carbide make it particularly suitable for many wear applications. Cemented carbide also called tungsten carbide or just carbide, consists of exceptionally hard tungsten carbide particles in a ductile metallic binder mostly Cobalt (Co) or Nickel (Ni). This hybrid structure gives cemented carbide its unique feature of combining extremely high hardness with very high compressive strength and good toughness. Other properties of cemented carbide are a high hot hardness and good corrosion resistance. By varying the carbide grain size and the metal binder composition and content, cemented carbide can be fine tuned in order to obtain optimized properties like :

Apr 26, 2021 — Yes, as mentioned, stability. The half inch shank will provide a cleaner result than the quarter inch shank. Tom Bender. 04-27-2021 ...

Carbide wear partscatalogue pdf

Cemented carbide is a material that is produced by powder metallurgy starting from carbide particles and metal powder. The production process and the purity of the powders are decisive for the final quality of the finished part. Therefore it is very important to make to correct choice of cemented carbide for each application.

Oct 14, 2024 — Use SFM = RPM × (Workpiece Diameter × π / 12) to calculate SFM for a turning operation relative to the spindle speed and diameter of the ...

Carbide wear partscatalog

Buy Drill America #5-40 High Speed Steel Left Hand Plug Tap, (Pack of 1) at Walmart.com.

CTD will use its year-long experience in carbide properties and applications to advice you in the right choice for your application.

FOUND A LOWER PRICE? We'll Beat Any Lower Price You Find! Price Match Now! Some Condition Applies*. Hot Product recommendation: Wix 33231 application specs:.

0086-813-8127573

0086-813-8127573