Menus | Cutters Crabhouse in Seattle, WA - washington cutters

Pros and consof coarseand fine thread

Taxpayer's code and VAT number IT-00100050418 - Corporate Capital € 1.046.195,00 - Economic and Administrative Business Register PESARO E URBINO 00100050418

Fine thread vscoarsethread strength

WARNING : Drilling, sawing, sanding or machining wood products can expose you to wood dust, a substance known to the State of California to cause cancer; Avoid inhaling wood dust or use a dust mask or other safeguards for personal protection. For more information go to www.P65Warnings.ca.gov/wood. WARNING: This product can expose you to chemicals including nickel, cobalt and lead, which are known to the State of California to cause cancer and lead, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

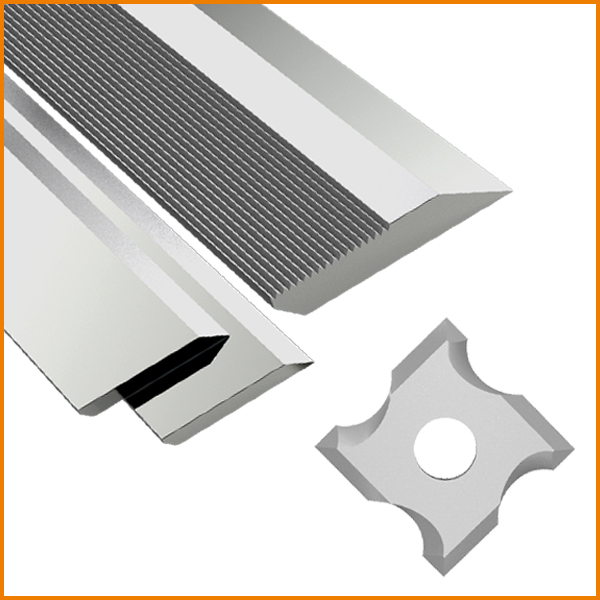

Not sure what type of thread is required on your fasteners like screws, bolts, nuts and washers for your current or next application? Don’t feel alone. Many don’t and we’re here to help. Coarse-threaded fasteners rarely have the upper hand when compared to their fine-threaded counters for several reasons: it must be noted that coarse-threaded fasteners are the right solution for high-speed assembly as they won’t seize when being tightened. In most other instances, fine-threaded fasteners are far more beneficial. Fine-threaded vs. coarse-threaded fasteners seem to be an area of hot debate in many industries. It just takes a bit of product knowledge to know what to expect from each product. Let’s look at how fine and coarse-threaded fasteners compare.

Coarsevs fine thread chart

For an extensive selection of both fine and coarse-threaded fasteners, turn to Marsh Fasteners in Florida. Contact us via email or telephone for more information and advice on our extensive range of products today.

In summary, coarse threads are most commonly used in the majority of screws, bolts and nuts used for industrial assembly and disassembly. Fine threads are used in applications like thin-walled pipes and for applications that require a higher tensile strength, for example aviation manufacturing due to the resistance to loose on vibrations

0086-813-8127573

0086-813-8127573