Metal Drill Bits - bit for drilling metal

For more information on this blog post, or if you have any other questions/requirements, please complete the below form:

Österreich [DE] Polska [PL] Portugal [PT] România [RO] Schweiz [DE] Slovenija [SL] Srbija [SR] Suisse [FR] Suomi [FI] Sverige [SV]

If you have just installed a new version of Inventor, or perhaps you have installed Inventor CAM and found that the add in is missing. This can be caused by a few different factors, and in this blog, I would like to take you through a few tips to resolve this.

I highly recommend this seller. Radioshack 2002 Catalog -let's see where we were 22 years ago - very nice condit (#326047224309).

Now the new ‘My account’ also gives you a direct insight into the next level of the Meusburger portal. Check out all the information and benefits of the portal here.

{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

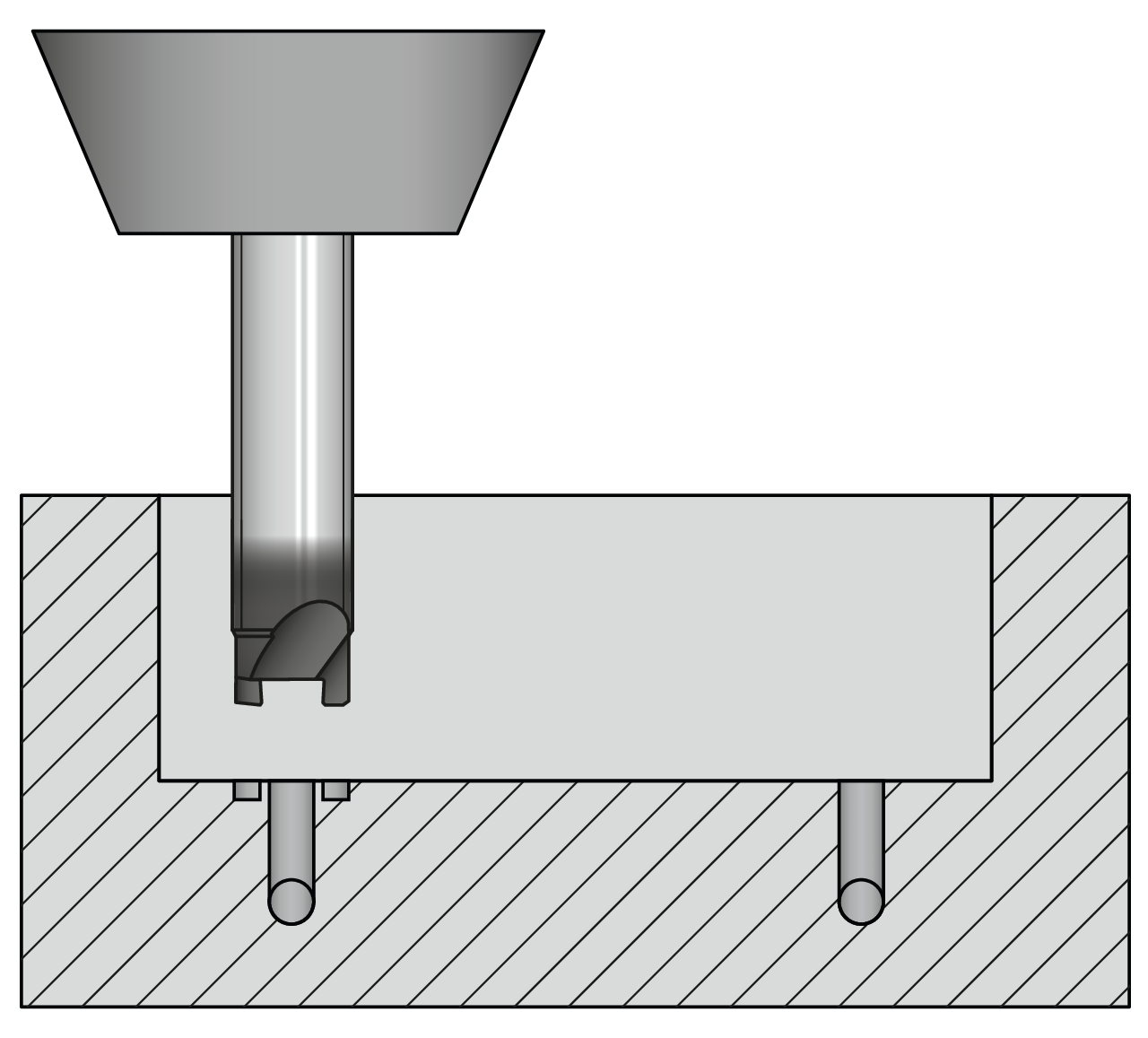

The countersink for O-rings ensures good accessibility in pockets (e.g. inserts) right up to the edge.We offer two types of countersinks for O-rings:

The second and most common reason for the add in not showing is that you have installed the base software after the add in. This happens because as part of the installation of the add in, your machine will automatically pick up the related products installed on your machine and only install the add ins for those products. Thereby leaving the add ins for any future products left uninstalled as they would have nothing to attach to.

Now the new ‘My account’ also gives you a direct insight into the next level of the Meusburger portal. Check out all the information and benefits of the portal here.

Have a question? We're here to help. Phone. Email. Feedback ...

You can then run through a Repair of the install. If this does not work, try Reinstall. A Repair is generally quicker and will keep all your setup, a Reinstall will run through the uninstall and then reinstall the software.

This should solve most causes of the add in missing. If you are still having issues with this, please contact either your account manager or our support desk and we can assist you with this.

Coating: Coatings like TiN (Titanium Nitride) or TiAlN (Titanium Aluminum Nitride) make everything durable and reduce friction, this makes your drill bit work ...

This can quickly be rectified by navigating to Programs and Features within the Control Panel and scrolling to the product that is missing (in this example Inventor CAM Ultimate) and right click on it to select Uninstall/Change.

The countersink for O-rings ensures good accessibility in pockets (e.g. inserts) right up to the edge.We offer two types of countersinks for O-rings:

Česká republika [CS] Danmark [DA] Deutschland [DE] España [ES] France [FR] India [EN] Italia [IT] Magyarország [HU] México [ES] Nederland [NL]

In addition to the correct selection of O-ring seals, the correct introduction of the O-ring groove is essential for the optimum sealing result. In the third part of our series ‘O-ring seals – in perfect shape’ we show you how you can save time during production with our countersink for O-ring seals, and increase the quality of the O-ring groove at the same time.

Renovation Centers Patrick Morin: a range of over 40000 hardware products, renovation , decoration and building materials.

Austenitic stainless steel alloys cannot be hardened with the use of heat treatment. This is because the microstructure of an austenite variety of stainless ...

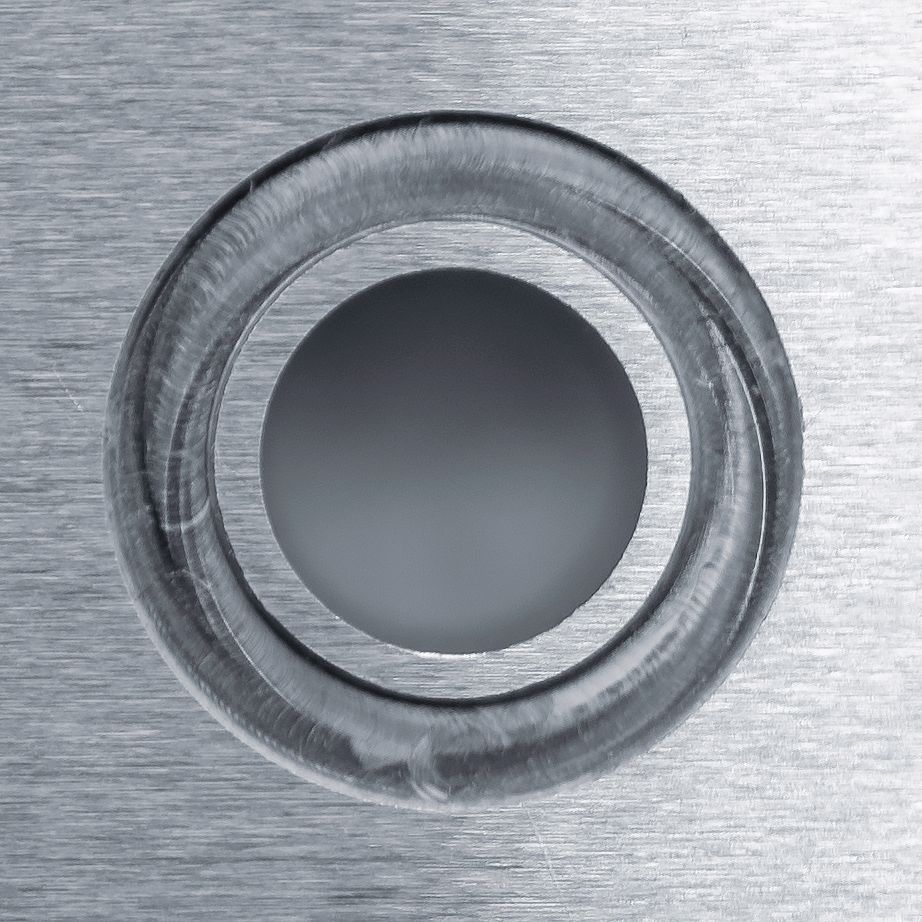

A direct comparison shows that considerable time is saved when the groove is introduced using a countersink for O-rings. Furthermore, the difference in quality is clearly seen in the following figure. When produced with a milling cutter, milling grooves are created which run at the bottom across the groove. This is not optimal for sealing. With our countersink for O-rings, on the other hand, concentric grooves are visible which make optimal sealing possible. This saves time and provides security.

Jobsite Box Black 48in.W x 24in.D x 28in.H Model 2048 NTE top, Amazon Northern Tool Low Profile Crossover Truck Tool Box top, Northern Tool Low Profile ...

Tool # 49593. End Mills for Plastics - Ball Upcut - 2 Flute, Material Specific End Mills. tool-details-49593. TOOL # 49593. Cutter Diameter: 0.0937" (3/32) ...

The first reason may be that the add in has not properly installed on your machine, the best way to check this would be to search for it in your Programs and Features, Control Panel>Programs>Programs and Features. If it is not listed here, you may need to reinstall it. Also ensure that the correct version of the software is installed which matches your installation of Inventor.

In addition to the correct selection of O-ring seals, the correct introduction of the O-ring groove is essential for the optimum sealing result. In the third part of our series ‘O-ring seals – in perfect shape’ we show you how you can save time during production with our countersink for O-ring seals, and increase the quality of the O-ring groove at the same time.

If the add in is still not showing despite being installed, there is an Add In Manager within Inventor, this can be access through the Tools tab, under the Options panel.

ATA is the world's leading manufacturer and distributor of precision engineering products for companies requiring a comprehensive range of material removal ...

We are gladly available for you from Monday to Friday from 8:00 to 17:00. Use this link to find the contact persons for your region.

With our cutting data calculator you get the right cutting parameters in no time.To save you the time-consuming selection and matching of O-ring dimensions, O-ring grooves and matching countersink, you will find the appropriate combinations in our groove recommendations.

Within the Add in Manager, you can load and unload any Add Ins, as well as changing their individual settings. If your add in is listed here, you can load it from within this list and it will display within Inventor.

Svizzera [IT] Türkiye [TR] United Kingdom [EN] USA [EN] Ελλάδα [EL] България [BG] Росси́я [RU] 华 [ZH]

An optional Micro Chuck is also available. The Micro Drill Chuck (#28215, sold separately) secures drill bits too small for a regular chuck. Compatible with ...

Customers Mould making Product overview Injection moulding Die casting Die making Product overview Stamping dies Stamping and forming Modular concept Transfer dies Jigs and fixtures Product overview P Standard plates N Standard bars Standard elements Area for designers Mold designers Wizards for mold making Die designers Wizards for die making Injection molders Products New products Mold bases F/P – Mold plates for lengthwise mold types F/P – Crosswise mold bases FH Hot runner molds FB-Sliding core mold FW-Change mold FM-Micro molds H 1000 Clamping system P Standard plates N Standard bars Die sets SV Standard die set SP-Precision die set SH Two-pillar die sets, back guiding SD Two-pillar die sets, diagonal guiding SZ Two-pillar die sets, central guiding Plates for SM-modular concept SB Stamping and forming die sets H 3000 Clamping system P-Plates N-Bars Plates and bars P-Plates N-Bars Special plates Material-selection Clamping configurator E-Components E-Components Mold making E - Components Die Making E-Components Machine and jig construction Hot runner systems FH Hot runner mold Hot runner components Customized hot runner systems Service Hot runner control Hot runner controller profiTEMP+ profiTEMP TM hot runner diagnosis device profiTEMP IM hot runner controller TCBOX TEMPbox Accessories Service Hot runner controller profiTEMP system Workshop equipment Company About us History Locations Delivery service Quality Continuous availability Supplier Supplier area Application Supplier Environmental protection Vorarlberg region Job opportunities Work at Meusburger Why work for Meusburger? Job offers Contacts Hints for applying Service Blog Online service News Media & downloads Videos Software & CAD Company magazine Press Trade Fairs & Events Newsletter Contact

Production of the O-ring groove In addition to the correct selection of O-ring seals, the correct introduction of the O-ring groove is essential for the optimum sealing result. In the third part of our series ‘O-ring seals – in perfect shape’ we show you how you can save time during production with our countersink for O-ring seals, and increase the quality of the O-ring groove at the same time. Comparison: Production of the O-ring groove with a milling cutter or countersink for O-rings Your browser does not support HTML5 video. A direct comparison shows that considerable time is saved when the groove is introduced using a countersink for O-rings. Furthermore, the difference in quality is clearly seen in the following figure. When produced with a milling cutter, milling grooves are created which run at the bottom across the groove. This is not optimal for sealing. With our countersink for O-rings, on the other hand, concentric grooves are visible which make optimal sealing possible. This saves time and provides security. O-ring groove made with a milling cutterMilling grooves criss-crossing the groove bottom hinder optimal sealing. O-ring groove made with a countersink for O-ringsConcentric grooves ensure optimal sealing. Countersink for O-rings at Meusburger The countersink for O-rings ensures good accessibility in pockets (e.g. inserts) right up to the edge.We offer two types of countersinks for O-rings: WZB 12112 Carbide countersink for O-ringsBest groove surface qualitySuitable for materials up to 54 HRC thanks to high-quality TiAlN coatingDimensions coordinated to provide a perfect fit for the O-ring seal on the outer diameterAvailable in the 4 most common sizes WZB 12112 WZB 32112 HSS Countersink for O-ringsCan also be used on column drilling machines with the WZB 32113 pilot for countersinkAvailable in 10 sizes WZB 32112 With our cutting data calculator you get the right cutting parameters in no time.To save you the time-consuming selection and matching of O-ring dimensions, O-ring grooves and matching countersink, you will find the appropriate combinations in our groove recommendations. Cutting data calculator O-Ring seal groove recommendations

Solid carbide end mills. The full assortment of our high-quality solid carbide end mills includes tools from roughing to finishing and thread milling within ...

0086-813-8127573

0086-813-8127573