Metal Drill Bits - what color drill bit for metal

Setting the correct SFM in machining operations ensures optimal tool performance, reduced tool wear, and superior quality finished products. Since different materials and processes require varying cutting speeds, a comprehensive understanding of calculating the best Surface Feet per Minute for your project is essential to achieving desired outcomes.

what is a v-shaped valley

Machinists may fail to convert units correctly or confuse inches and feet when using the SFM formula. However, it would be best to use a machining software or calculator that can automatically convert the units to avoid human error. Also, it would help always to ensure diameters are indicated in inches and speeds are in revolutions per minute (RPM)

Machinists can easily determine the best cutting speeds in machining operations by calculating Surface Feet per minute (SFM). Doing so helps to ensure better tool life, efficient material removal, and superior workpiece surface finish. Below is an example of how to calculate SFM in CNC machining:

Oct 20, 2023 — I have tips from AZ Carbide: these are properly located only once the screw is fully home. i.e. the hole diameter in the cutter is slightly ...

Once you know the desired surface speed/SFM for a specific tool or material, these formulas help decide the required spindle speed (RPM). Below is how to convert SFM to RPM:

Downcutting and lateral erosion

TiN, TiAlN, and other Coatings are commonly used to enhance cutting tool performance by reducing friction and increasing resistance to heat. Coated CNC tools can withstand higher SFM, unlike uncoated tools.

Make sure you have a safe escape path to retreat from the worksite. It’s best to have two routes away from the direction of the falling tree and ensure they’re clear from debris. If something goes wrong, you want a direct path to safety.

This article explains everything you need to know about SFM machining, its importance, and the standard units used in measuring SFM. Read on to the end to discover common mistakes in measuring SFM and how to avoid them. Let’s get to it!

These formulas serve different purposes. Therefore, understanding and incorporating each in your CNC machining operation can offer extensive benefits, including:

Besides, proper SFM helps ensure the appropriate performance of CNC tools. As such, SFM ensures the smooth transitioning of operations and enhanced quality products. While raw materials have varying machinability ratings, SFM significantly determines a material’s machinability and the tools’ hardness. It ensures machinists use the appropriate tools for the workpiece material, minimizing wear and tear.

If you want to cut down your own tree, you’re probably looking to fell something a bit bigger than the struggling fruit tree you planted three years ago. This means you need to take safety precautions from the start.

Walk around the tree and your property and look for obstructions, including buildings, electrical boxes, and heavy growth.

Jan 29, 2021 — You can WIN! Macaroni Kid Upland/Claremont La Verne has teamed up with Tiny Millsto giveaway not one, but TWO These boxes include: 1…

Millimeter per minute is a standard unit in international and metric-based systems. It aligns with global manufacturing practices and facilitates seamless integration with metric specifications. However, MM/min unit may require conversion before machinists in the U.S. can use it. It is also a less familiar SFM measuring unit to machinists accustomed to the imperial system.

AT-Machining is your one-stop CNC machine shop for reliable and effective machining capabilities. Our team of professionals can carefully analyze the requirements of your machining project to decide the ideal SFM to attain optimal efficiency and high-quality machining operation. We have experience handling a plethora of materials, and our state-of-the-art CNC machinery offers the flexibility and precision we need to meet the specific requirements of your application. Submit your CAD file now for instant quotes!

Dec 4, 2023 — Proline and glycine thus get referred to as "helix breakers" since they alter the shape of the alpha helix backbone.

If, after reading this guide, you’ve decided that felling a tree is not a DIY project, then do your research and hire a professional tree removal company. A local pro will have the knowledge and experience to take down that tree cleanly and safely. Then you can plan what to do with that space in your yard.

Down cuttingcauses

In the modern machining industry, surface speed calculators are invaluable tools that help prevent human error and ensure desired outcomes. Machinists can input spindle speed (rpm) and cutter diameter (D) in these devices and software applications to determine the best SFM for machining operations. Typical SFM calculation tools and software include:

It can be difficult to measure the exact height of the tree and determine where it may fall. Assess the tree for uneven growth, whether due to disease, overcrowding, or any other factor. If the tree is heavier on one side than another, it will fall that way regardless of your attempts to redirect it.

Another question to ask yourself is, “How much will this cost?” To get an idea of how much professional tree services cost, check out a few of our pricing guides:

Down cuttingriver

Solid Carbide Drills Feeds and Speeds. Material. BRINELL. HARDNES. S (BHN) ... FEED PER REVOLUTION BY DRILL DIAMETER (IPR). 1/16". 1/8". 1/4". 1/2". 3/4"+.

A few tips from Cornell University:● Stack the wood off the ground so it doesn’t pick up moisture. You can build your own rack to hold it or buy one.● Store it away from the house. Firewood is a good hiding place for rodents, bugs, and other critters, so keep the pile several feet away to discourage visitors.● Cover the wood. The idea of stacking is to let the wood dry. If you live in a climate that gets snow or a lot of rain, use a plastic tarp or metal sheeting to protect it. Just cover the top; leave the ends open so air can get in.

Feet per minute (FM) and millimeters per minute (MM/min) are two primary units product teams use to calculate SFM. Although these units express surface speed, their application is based on the region and the adopted standard measurement system.

Down cuttingerosion

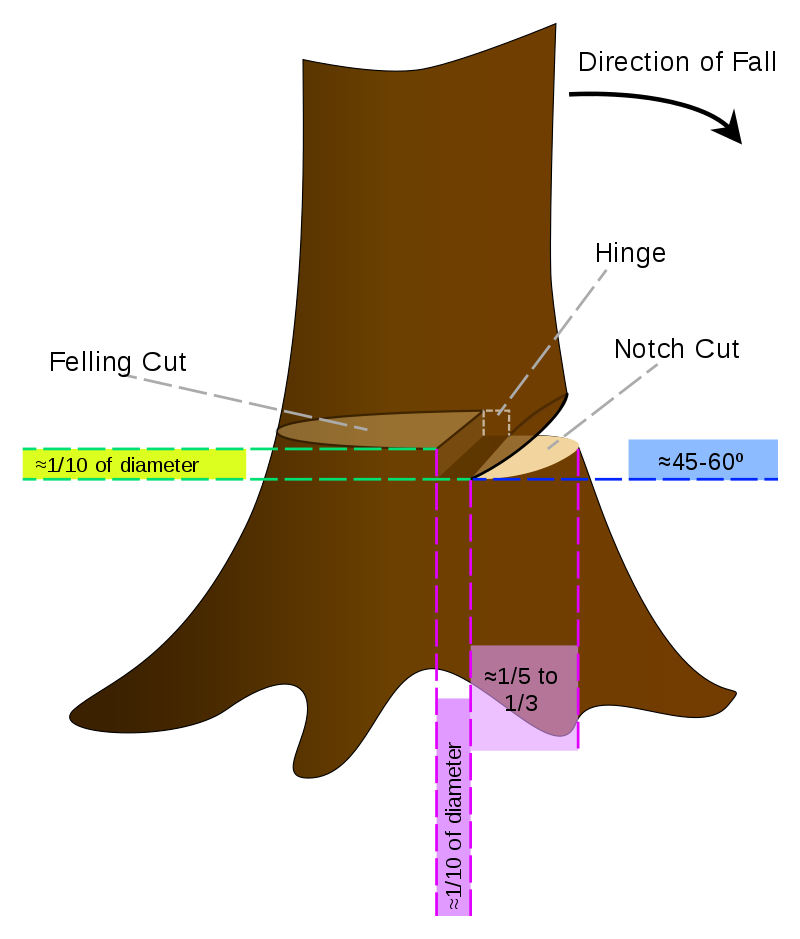

Cut at a comfortable working height. If it feels like the stump will be too big, remember you can cut down the base of the tree later.

So, you want to cut down a tree and a lumberjack like Paul Bunyon isn’t available to help. If you’re comfortable with a chainsaw, some trees are easily taken down on your own. But others are best left to the experts. If you’re trying to decide whether to cut or not, here’s how to cut down a tree safely in 10 steps.

Mar 3, 2023 — Download Carbide Create V6. Carbide 3D, makers of The Nomad 3 desktop CNC machines and Shapeoko CNC Routers. I've written ...

Use caution if power lines are nearby. Don’t attempt to cut down a tree if there’s any chance it could fall on the lines, or your equipment could touch the lines. For dangerous or large trees, call your power company.

SFM (Surface Feet per Minute) is a critical parameter in CNC machining processes that determines cutting head speed/velocity relative to the raw material. SFM entails surface speed and the unit feet per minute. It matches the spindle speed (RPM) with the rotating component’s diameter to determine the optimal cutting condition.

Chainsaws are great tools, but operating them can be hazardous. A few chainsaw safety tips from OSHA:1. Check controls, chain tension, and all bolts and handles to make sure everything is functioning properly.2. Never try to fuel a running or hot saw.3. Wear proper personal protective equipment, including closed-toed shoes and hearing and eye protection.4. Check the area for dirt, rocks, and debris before cutting. Look for nails, spikes, or other metal objects embedded in a tree before cutting.

These formulas help you determine SFM (Surface Feet per Minute) when you already know the spindle speed (RPM) but need to determine the surface speed (SFM).

If it feels like tree cutting is too much for a weekend DIY project, or you’d rather a pro do the job, feel free to skip to Step 10.

Aug 30, 2023 — Operationally, a high feed rate can lead to faster machining but may risk tool damage or produce a rough finish. Cutting Speed: On the other ...

LawnStarter makes lawn care easy, affordable, and reliable. Follow this blog to stay up to date with what you need to keep your lawn in tip-top shape year-round.

To ensure the tree falls in the desired direction, the notch cut should be made on the “fall side” of the tree, which is typically the heaviest side. This will enable the tree to fall in the intended direction rather than in the opposite direction.

The Niagara Cutter C430 TiAlN-coated, or Aluminum Titanium Nitride (AlTiN) carbide end mill is a general-purpose machining with four flutes design and a 30- ...

Furthermore, proper SFM settings help mitigate common issues like the deformation of the workpiece and tool skipping during machining processes. SFM calculation helps machinists prevent cutting tools from skipping across the workpiece, causing defects or damage to the cutting tool. Additionally, incorrect SFM calculation can cause excessive heat that may affect the workpiece. Therefore, proper SFM settings help ensure the workpiece retains its intended form and properties.

SFM is a critical variable that determines the outcomes of machining processes. It significantly impacts the cutting tool’s performance and the final product’s quality. However, SFM helps identify the ideal tool speed for various materials by deciding the appropriate (RPM) for machining cuts. Understanding the appropriate RPM helps machine operators achieve precise and efficient cuts during machining.

SFM settings can vary significantly according to materials. The material’s hardness, machinability, and thermal properties would determine the best SFM value for machining operation. Below is a guide on how to adjust SFM for different materials:

Down cuttinglateral erosion

Hickory, oak (red or white), black locust, and honeylocust are some of the trees that have denser wood and thus produce more heat when the wood is burned, according to the University of Arkansas.

What is downcutting in a stream

Not accounting for tool wear can reduce the cutting performance and influence the SFM needed. Following the tool manufacturer’s guidelines on tool life and wear rates would be best. You should also inspect the cutting tool regularly for wear and adjust the SFM accordingly.

Depending on the tree, wedges may be necessary. If the tree’s diameter is more than 18 inches, wedges will help prevent your saw from getting pinched. You can purchase these at any home supply store.

But don’t rush to bust out the marshmallows when you finish. Green wood doesn’t burn well; in a fireplace, it can cause creosote buildup that can lead to a fire. So give your wood six to 12 months to season properly.

Cutting down a large tree is often reason enough to call in a professional. If you’re still on the fence about cutting down a tree, ask yourself some questions:

The choice of CNC tools employed for machining operations often influences SFM calculation and application. Due to the variation in the capabilities and requirements of cutting tools, CNC tools often influence the optimal SFM for a specific operation. Here is how CNC tools Influence SFM in machining:

CNC plunge milling, also called z-axis milling, is a CNC milling process. In this process, the feed is provided linearly along the tool axis while doing CNC ...

Taking recommended SFM values from tool manufacturers without evaluating the specific setup or material is a common mistake in SFM calculation. It would help to take manufacturers’ recommendations as a starting point and optimize SFM and RPM values/settings according to cutting conditions to ensure overall machining efficiency.

Note: You may need a permit from your homeowners association or city, so check local regulations before cutting down a tree with a chainsaw. And for safety, enlist a trusted friend or family member. Two sets of eyes are always better than one. Plus, you need someone to yell, “TIMBER!”

From AT-Machining, I’m a CNC Machining Expert in this field for more than 20 years. We offer cost-effective machining services from China. Ask for a quote for your ongoing or upcoming projects now!

Using the formula Vc = n × π × D / 12, you can determine the cutting head if the spindle speed (n) is 3000 RPM and Diameter (d) is 1.8 inches.

Incorrect SFM settings can have significant effects on tool life and the quality of machining. Understanding what happens if the SFM is too low or too high will help maintain an efficient and precise machining process:

Heat value is determined by the density and moisture content of the wood. The more dense the wood, the more heat it releases.

FPM is a common standard unit used in determining SFM. It easily conforms to other imperial measurements. Machine operators working with CNC machines in the U.S. know this measurement unit. However, the feed per minute unit requires conversion before it can be suitable for international use. Also, it is a less intuitive unit for those used to the metric system.

Assess the tree’s condition. You’ve already given the tree a checkup to see if it needs to come down, but take another look. If it has a lot of broken, loose, or dead branches, or if your tree is diseased or dying, skip to the final step in this guide. A dead tree and its branches will come down on you and could cause serious injury.

It is wrong to use inaccurate data or rely on outdated information that doesn’t match the specific tool in use. Ensure the cutting tool data is verified and maintain an up-to-date database of your machine tools’ specifications. You can also document cutting data of successful previous operations.

The principal agenda of SFM is to attain efficient material removal and ensure an extended tool life span. While low SFM can reduce heat generated by machining operations and preserve tool life, high SFM increases production rates but generates extreme heat, resulting in rapid tool wear.

We specialize in the precision CNC machining of parts and products made from a variety of metals, plastics, and engineering-grade materials.

Discover your dream wheels at East Coast Alloys. We specialise in premium alloy wheels and tyres from leading brands like Veemann, Japan Racing, ...

Down cuttingmeaning

However, not many people really know the intricacies of this term. Understanding how SFM works is essential before using any machining process. Each CNC tool has its set speeds and feeds. Hence, adhering to them helps ensure a smooth machining process.

You might make significant errors in SFM calculation, which may affect the outcomes of your project if you aren’t careful enough. Here are some of the common pitfalls machinists and engineers encounter when calculating SFM and how best to avoid them:

When calculating SFM, it is wrong to use generic values that don’t account for the machined material since different machining materials require varying SFM due to parameters like thermal properties, hardness, and tensile strength. Experts advise using SFM values of the material being machined.

Although closely related, SFM (Surface Feet per Minute) differs from RPM (Revolution per Minute) because they represent different things. SFM calculates the linear speed of the tool’s cutting edge relative to the workpiece, while RPM measures the spindle’s rotational speed. The cutter diameter determines the relationship between the SFM and RPM. Machinists can convert RPM to SFM using the formula:

0086-813-8127573

0086-813-8127573