Metric Speeds and Feeds - cutting speed for aluminum milling

Replace some of the iron found in M2 tool steel (and all steels, for that matter) with cobalt and you get “super high-speed steel.” The addition of 5% cobalt, for instance, gives us M35 tool steel, while 8% cobalt and some additional molybdenum make M42 tool steel—whenever anyone talks about cobalt drill bits, they are referring to one of these two.

Our Screw Machine Products find application in a wide range of industries, including automotive, aerospace, electronics, medical, telecommunications, and more. Whether it's precision components for automotive engines, intricate connectors for electronic devices, or specialized parts for medical equipment, our products are trusted by leading companies worldwide.

The M-series, for instance, gets its name from the primary alloying ingredient, molybdenum, a hard, heat-resistant element sitting at number 42 on the periodic table. M2 tool steel—the stuff of most drill bits—contains 5% molybdenum, but there are also M50, M7, and a few others, all of which provide differing degrees of flexibility, hardness, and toughness needed for holemaking operations.

At 82 HRC, give or take, tungsten carbide is much harder than cobalt or HSS. This is carbide’s only Achilles’ heel—where cobalt will flex a fair amount in the face of radial cutting forces, carbide will in many cases shatter. This means that proper alignment is critical for tool life and hole accuracy (which is true of any drilling operation). And when breaking through into intersecting holes as in the manifold example just given, the feedrate should be reduced slightly until the drill stabilizes.

YASAM Side-locking ENDmill extension holder for longer end mill. $20.00 - $100.00. Min. Order: 5 pieces.

That’s not to say cobalt is obsolete, however. For prototype work and low-volume jobs, carbide’s higher cost probably doesn’t make sense. Nor is it appropriate for repair work or unstable machining conditions, where deflection can lead to disaster. Cobalt is also more suitable for softer materials like mild steel or aluminum, although here again, carbide's greater hole quality and straightness easily justify its use in higher-volume applications. At the end of the day, choosing the right tool means doing the math, asking questions, and being open to new technologies. Get drilling.

Jul 24, 2017 — Just got an email from Carbide3d (makers of the shapoko cnc) that they are letting ppl download and use their software free of use.

There’s neither the time nor space for a complete lesson on tool steels. Those interested can read more about it in this sample from ASM International’s Handbook, Volume 16: Machining Handbook. Otherwise, just know that so-called Mushet steel, which most consider the first true tool steel, left the furnace more than 150 years ago.

Thread rolling is a type of threading process which involves deforming a metal stock by rolling it through dies. This process forms external threads along the surface of the metal stock...

Provide your project details, and we'll connect you to 5-20 qualified screw machine product companies in your region. 100% free.

This last question is a good one. The answer comes down to the job quantity, machine setup and rigidity, and available budget. Let’s start with expense. As with anything that offers greater performance, carbide cutting tools cost significantly more. How much more depends on the manufacturer and tool geometry, but you can figure at least twice the price for substantially greater tool life and perhaps 10-20 times the metal removal per drill.

Our extensive range of Screw Machine Products is manufactured with utmost precision and adherence to stringent quality standards. We employ state-of-the-art screw machining technology, coupled with advanced CNC (Computer Numerical Control) equipment, to ensure exceptional accuracy and consistency in our products. From simple to complex geometries, we have the expertise and capabilities to meet the most demanding specifications.

Who ownsroberts machine products

As to the question “when should a cobalt drill bit be used," the answer is straightforward: anywhere you would use an HSS drill. Cobalt, however, will in most cases last longer than its less wear and heat-resistant cousin, and as we've seen, run much faster besides. The only caveat is that cobalt drills, due to their greater hardness, are more brittle than HSS. The user must therefore take extra care to align them properly and avoid the radial tool pressures that might occur when drilling into intersecting holes (hydraulic manifolds, for example) and angled surfaces.

Roberts Automatic Products Inc. | Screw Machine Product | Home | Request for Quote | Photo Gallery | Privacy Policy/Terms of use | List of Companies | Sitemap

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Screw machined parts are complex pieces that are typically cylindrical and threaded and a screw machined product is a family of automatic lathes for small to medium-sized components. Screws, bolts, pins, fittings...

That brings us to tungsten carbide, more commonly referred to as carbide or sometimes cemented carbide. Think of it as cobalt on steroids. It's been around for nearly one hundred years but didn't come into widespread use as a cutting tool material until after World War II, when Kennametal founder Philip M. McKenna developed the first indexable carbide cutting tools. Since then, this extremely hard and wear-resistant material has consumed an enormous swath of the cutting tool market, drill bits included.

6. Continuous Improvement: We are committed to continuous improvement in all aspects of our operations. Through ongoing investment in technology, process optimization, and employee development, we strive to enhance our efficiency, quality, and customer satisfaction.

Milwaukee® 48-89-9212 Step Drill Bit, 7/8 in Dia Min Hole, 1-3/8 in Dia Max Hole, 5 Steps, HSS, 4 Hole Sizes, 3/8 in Shank ; Minimum Hole Diameter: 7/8 in ...

In addition to our exceptional manufacturing capabilities, we offer a comprehensive range of services to support our customers' needs. These services include:

Because it could cut metal much more quickly than the hardened carbon steel tools of the day, they dubbed it high-speed steel. As you will see, that moniker has since become a bit misleading, as tungsten carbide cutting tools—though a bit less forgiving than HSS—are far faster and therefore much more productive.

4. Just-in-Time Delivery: We understand the importance of timely delivery. With efficient production processes and a well-established supply chain, we offer flexible and reliable just-in-time delivery options to meet our customers' production schedules.

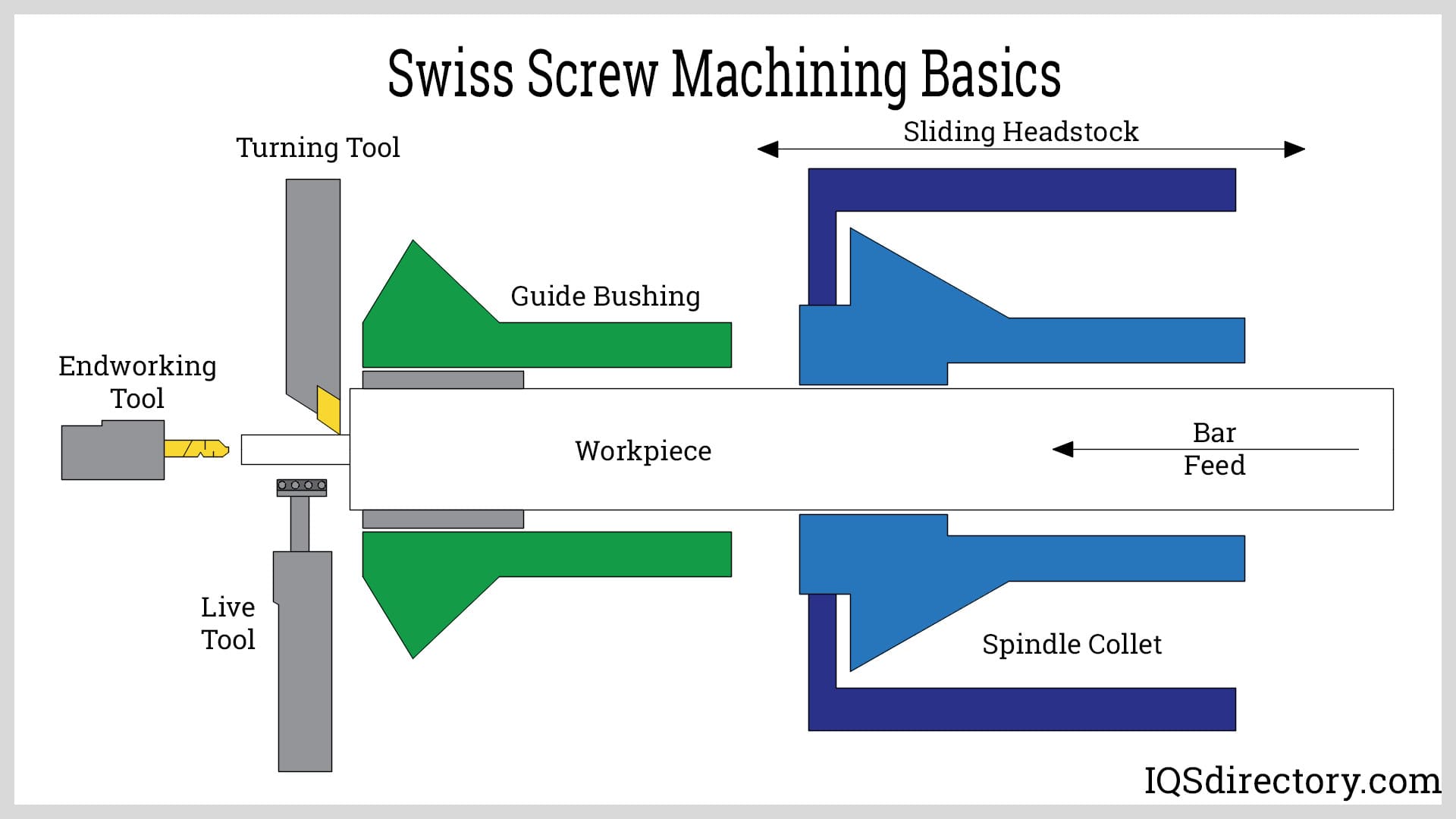

Swiss screw machining is a process for producing high precision parts in high volume using an automatic lathe that is programmed to perform every aspect of the cutting process. The method used for Swiss screw machining is unlike other forms of screw machining...

Roberts Automatic Products Inc. is a renowned manufacturing company specializing in the production and distribution of high-quality Screw Machine Products. With a rich history spanning over several decades, we have established ourselves as a leading provider of precision-engineered components and parts for a diverse range of industries.Our extensive range of Screw Machine Products is manufactured with utmost precision and adherence to stringent quality standards. We employ state-of-the-art screw machining technology, coupled with advanced CNC (Computer Numerical Control) equipment, to ensure exceptional accuracy and consistency in our products. From simple to complex geometries, we have the expertise and capabilities to meet the most demanding specifications.At Roberts Automatic Products Inc., we understand the unique requirements of our customers, and we strive to provide tailored solutions that address their specific needs. Our dedicated team of engineers and technicians work closely with clients throughout the entire manufacturing process, from initial design and prototyping to final production. We are committed to delivering products that not only meet but exceed customer expectations in terms of quality, performance, and reliability.Our Screw Machine Products find application in a wide range of industries, including automotive, aerospace, electronics, medical, telecommunications, and more. Whether it's precision components for automotive engines, intricate connectors for electronic devices, or specialized parts for medical equipment, our products are trusted by leading companies worldwide.In addition to our exceptional manufacturing capabilities, we offer a comprehensive range of services to support our customers' needs. These services include:1. Custom Design and Engineering: Our experienced engineering team collaborates with clients to develop custom solutions, providing expertise in design optimization, material selection, and manufacturability analysis.2. Prototyping: We offer rapid prototyping services to help clients visualize and test their designs before full-scale production. This enables faster time-to-market and reduces the risk of costly errors.3. Quality Assurance: Quality is at the core of everything we do. Our robust quality management system ensures that every product undergoes rigorous inspection and testing to meet the highest industry standards.4. Just-in-Time Delivery: We understand the importance of timely delivery. With efficient production processes and a well-established supply chain, we offer flexible and reliable just-in-time delivery options to meet our customers' production schedules.5. Value-Added Services: Beyond manufacturing, we provide additional value-added services such as finishing, assembly, and packaging to deliver a turnkey solution to our customers.6. Continuous Improvement: We are committed to continuous improvement in all aspects of our operations. Through ongoing investment in technology, process optimization, and employee development, we strive to enhance our efficiency, quality, and customer satisfaction.Roberts Automatic Products Inc. takes pride in our commitment to excellence, innovation, and customer satisfaction. With our advanced manufacturing capabilities, comprehensive services, and customer-centric approach, we are the preferred partner for Screw Machine Products for businesses across industries.

Apr 22, 2015 — Beautiful Clothing, Jewelry & Accessories

www.victoriantradingco.com • 800.800.6647 Myriad Moondrops

It’s this last group, HSS, that we’re here to discuss today, along with that most widely used of all cutting tools, the drill bit. Despite their broad popularity, relatively low cost, and excellent mechanical properties, you’ll soon see why HSS and its cobalt counterparts aren’t always the best cutting tool materials for your drilling application. Read on.

GOdrill™ features grade KC7325 – a multilayered PVD TiN-TiAIN coated fine-grain carbide with a TiN top layer for better wear identfication. This multipurpose grade has been combined with a unique general-purpose cutting geometry to offer high versatility and reliability across all material groups at intermediate cutting conditions.

Machine shops, maintenance personnel, and the manufacturing community overall face off against a veritable universe of different materials each day:

5. Value-Added Services: Beyond manufacturing, we provide additional value-added services such as finishing, assembly, and packaging to deliver a turnkey solution to our customers.

Plastic cover to protect tire tool. Our mission at CanadianAutoEquipment.ca is to bring our customer's the highest quality 4 post lifts, tire changers and ...

Compared to regular M2 tool steel, M35 and M42 are indeed super. Where "regular" M2 HSS comes in at a hardness of around 62 HRC, M35 starts at 65 HRC and M42 measures 67 or so. That doesn't seem like much difference, but together with cobalt's greater heat resistance, it supports higher cutting speeds—depending on the brand and whether the drill is coated, this might mean 50% faster spindle RPM and commensurately higher feedrates. Either way, be sure to follow the cutting tool manufacturer's recommendations.

A similar argument can be made for everything from high-end kitchen appliances to CNC machine tools, and if your shop has one of the latter, don’t short-change its potential by using low-cost drills and other cutting tools. Not only does carbide provide cutting speeds at least four to eight times that of cobalt, but far higher feedrates as well. And because carbide drills also support a feature unavailable with their cobalt cousins—coolant through-the-tool—there’s no need to peck. When coupled with high-pressure coolant (HPC), solid carbide blows the doors off traditional drills.

Roberts machine productscatalog

20231015 — RPM x FPT x Flutes will get a feed rate. Both these formulas won't help much if you don't already know the SFM for different materials. There ...

Roberts Automatic Products Inc. takes pride in our commitment to excellence, innovation, and customer satisfaction. With our advanced manufacturing capabilities, comprehensive services, and customer-centric approach, we are the preferred partner for Screw Machine Products for businesses across industries.

Roberts Automatic Products Inc. is a renowned manufacturing company specializing in the production and distribution of high-quality Screw Machine Products. With a rich history spanning over several decades, we have established ourselves as a leading provider of precision-engineered components and parts for a diverse range of industries.

© Screw Machine Product will keep your information private and secure. We will not share your email address with any third parties.

Name: Tapered cross drill bit for quarrying, mining, tunneling. Brand name: Firip. Diameter: 28/30/32/34/36/38/40/42/46/48/50/55/60/65/70/80/90/100/120 etc.

This last point is important, since all cutting tools, whether they are HSS, cobalt, or tungsten carbide (more on this shortly), benefit from coating, be it TiN (titanium nitride), TiAlN (titanium aluminum nitride), or one of the other many tool coatings available on the market today. It’s also important to note that, despite what some websites suggest, there’s no such thing as a titanium drill bit (only drill bits coated with one or more of the thin film materials just mentioned).

This list is by no means complete, but we’d be remiss in not tagging a few members of the tool steel family. These include D2, A2, H13, S7, and other tough, heat-treatable, and wear-resistant metals used to make everything from plastic injection molds to stamping dies to high-speed steel (HSS) cutting tools.

1. Custom Design and Engineering: Our experienced engineering team collaborates with clients to develop custom solutions, providing expertise in design optimization, material selection, and manufacturability analysis.

2. Prototyping: We offer rapid prototyping services to help clients visualize and test their designs before full-scale production. This enables faster time-to-market and reduces the risk of costly errors.

3. Quality Assurance: Quality is at the core of everything we do. Our robust quality management system ensures that every product undergoes rigorous inspection and testing to meet the highest industry standards.

EDM machining is a contemporary machining method based on the removal of material from a part using thermal energy. The material is removed by local melting or vaporizing small areas on...

Since we’re comparing cobalt drills to those made of carbide, we won’t delve too deeply into the different types of carbide drills except to say that solid carbide is the closest equivalent from a size, length, and application perspective. After this come replaceable tip modular drills and indexable insert drills for larger holes (say anything above 1-1/2" in diameter).

CNC machining is an electromechanical process that manipulates tools around three to five axes, with high precision and accuracy, cutting away excess material to produce parts and components. The initial designs to be machined by CNC machining are created in CAD...

Regardless, metallurgists have continued adding various amounts and kinds of alloying elements to the tool steel crucible, among them tungsten, vanadium, chromium, and, most relevant to this discussion, cobalt. The result is six distinct groups of tool steel and many dozens of grades, a few of which we mentioned previously.

At Roberts Automatic Products Inc., we understand the unique requirements of our customers, and we strive to provide tailored solutions that address their specific needs. Our dedicated team of engineers and technicians work closely with clients throughout the entire manufacturing process, from initial design and prototyping to final production. We are committed to delivering products that not only meet but exceed customer expectations in terms of quality, performance, and reliability.

Kegerator Kits · Beverage & Gas Tubing · Gas Cylinders · Shanks & Wall Kits · Shop All · Draft Parts · Dispensing Kits · 1-Tap · 2-Tap · 3-Tap · 4-Tap ...

Precision turned parts are machined with extreme care to reach exceptionally tight tolerances using Swiss and CNC machining or turning. The processes of precision turning involve a variety of methods that include facing...

Oct 2, 2017 — The SFM calculation utilizes the industry standard of 3.82. Here, the cutter diameter of the chosen tool is multiplied by the speed or RPM. This ...

The Fulton Taper Jig which has been designed for the sole purpose of cutting long tapered angles on your table saw!

0086-813-8127573

0086-813-8127573