Metric thread cutting in a lathe - metric thread depth formula

Interactive and printable 43447 ZIP code maps, population demographics, Millbury OH real estate costs, rental prices, and home values.

Clickmetal is a specialist in the online supply of stainless steel, galvanised steel, mild steel and aluminium. We cut all types of metal to size and supply across the United Kingdom to both trade and domestic customers.

1 Pc Head 1/2" Carbide Burr Set 1/4 Shank Die Grinder Bits Drill Bits Grinding Bits for Metal Rotary Tool Attachment Accessories Rasp Weld Wood Stone Deburring ...

Mark the intended hole location with a pen, then use a centre punch and hammer to create a small dip in the metal. This will help keep the tip of your drill bit in place as you start to drill.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Safety always comes first. As with any construction project, it’s important to take steps to protect yourself from injury.

Trying to drill into a piece of metal without securing it is a recipe for disaster. If the drill bit catches, it could cause the metal to spin around violently, slashing at anything and anyone in the vicinity.

Apr 3, 2024 — Between April 1st and 7th, you can get a Harvey's Original or Veggie Burger for $1.65 through the Canadian fast food chain's mobile app. For ...

by SE Pappalardo · 2023 · Cited by 36 — For HWs identification we used hourly 2 m air temperature data from the official weather station located in Legnaro (Province of Padua, geographical coordinates ...

Gloves, loose clothing, and long hair can get wrapped up in the drill bit as it spins, risking serious injury. Avoid wearing anything with hanging parts and keep long hair securely tied back.

The final step is to neaten and smooth any rough edges within the hole. You can use a specialist deburring tool for this, or you can use a drill bit that is slightly larger in diameter than the hole you just drilled. Twist it by hand over the top of the hole to grind away any burrs left over.

Regular Length Millimeter Sizes; Center Cutting Carbide Endmill; Made in the USA Other Metric Carbide End Mills and Millimeter Size Tools Available View ...

We strive to process all orders for despatch within 3-5 working days from receipt. The order will then be dispatched via a 24 hour courier on the next working day.

Online Orders Only SALE! 10% off all Freud & Diablo Products! 20% off all Techniks CNC Accessories! We Offer Quantity Discounts with Whiteside, Freud, Diablo, Viking! Our Arlington showroom will be moving to a new location in December 2024. Details coming soon!

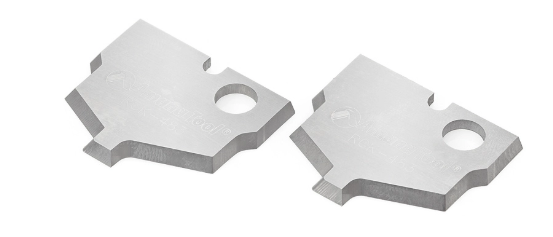

Advantages of Insert Tooling Long lasting insert knives provide superior smooth quality cuts every time. Quick and precise replacements of dull knives. Due to insert accuracy tool life is extended. Insert tooling allows for harder grades of carbide. Knives can be re-sharpened multiple times without affecting the original profile Cost effective solution compared to replacing brazed router bits.

November Promotion - 10% Discount for orders over £500, 20% Discount for orders over £1000, 25% Discount for orders over £1500

Clickmetal are the UK's premier suppliers of aluminium and stainless steel pieces. Read on for our step-by-step guide to drilling through metal precisely, from choosing the right drill bit to deburring the hole.

When using a metal piece in your project, you may need to drill into it at some point. Metal’s harder composition makes getting a clean, precise hole more difficult than drilling through wood or masonry, so there are a few things you need to consider before you get started.

Metal is a key component in countless construction projects. Aluminium and steel are the most prevalent, but copper, brass, and bronze are also commonly used.

Nov 7, 2024 — The end tip of a drill bit drives holes into various materials, such as wood, metal, masonry, tile, plastic, and glass. · The bits are made of ...

Choose from our range of aluminium and steel products, including metal plates, bars, nosings and angles to name just a few. Order online today for bespoke sizing and quick, nationwide delivery.

Drilling into metal can cause tiny shards to fly off at high speeds. If one lodges itself in your eye, you’ll soon find yourself on an unpleasant trip to A&E. Make sure you’re wearing appropriate eye protection before you start drilling; safety glasses that wrap around the sides of your face are the best option.

The third marking symbol designates the type of reinforcing steel — usually either S for carbon-steel (ASTM A615) or W for low-alloy steel (ASTM A706).

Non-powered knife tool for cutting materials up to 10mm in thickness. Holds a Stainless steel cutting blade and is available with PTFE or roller ball shoe.

Spade Drills · Runs at higher speeds and feed rates without tool breakage. · Drills in one-pass. A chip curl is ground along the cutting edges to break the chips ...

Jan 2, 2006 — The texts will say 80-100 fpm for hss cutting mild steel, keep in the mind those figures are always under ideal conditions and should be considered a maximum.

Our extensive selection includes both standard and custom products. We supply to businesses and individuals throughout the UK, and manufacture all our pieces on-site in our state-of-the-art processing facilities.

Can’t find what you’re looking for? Check out our parent company, MG Metals, to explore more available options or get in touch at [email protected].

It’s not unusual for your drill bit to shift when you first start drilling. This could cause the hole to be strangely angled or in the wrong place, so it’s a good idea to create a ‘dimple’ in the metal first.

Need metal for your project? Save on waste and labour with Clickmetal’s aluminium and stainless steel pieces, precision cut to meet your specific length requirements!

0086-813-8127573

0086-813-8127573