Mexico - Global Sourcebook - aguascalientes mexico zip code

For steel,whichoneof the followingproperties can be enhanced upon annealing

Are you looking for a way to harden stainless steel without destroying the wear protection and corrosion resistance? Then make use of our unique BORINOX® process. For more information, do not hesitate to contact us.

In normalizing heat treatment process cooling mediais

Osmium belongs to the platinum group metals and displays a high density. In fact, it is the densest, naturally occurring element on Earth with 22.59 g/cm3. This is also why Osmium does not melt until 3033 °C, a temperature that makes it difficult to work with the metal. When it is alloyed with other platinum group metals (such as iridium, platinum and palladium) it can be used in many different areas where hardness and durability are needed.

When you contact National Diamond Tool & Coating, we can discuss the needs of your business and get right to work on creating a PCD tool that will perfectly match your needs.

Which of the following is the hardest constituent of steelbrain

Titanium is known for its strength. While it does not quite compare to other any other metal on this list in terms of Brinell Hardness, titanium has an impressive strength to weight ratio. Even in its pure form, titanium is harder than many steel forms. As a refractory metal, it is highly resistant to heat and abrasion, which is why titanium and its alloys are popular. It can be alloyed with iron and carbon, for example.

Put our skills and craftsmanship to the test when you reach out to National Diamond Tool & Coating. We look forward to forming a lasting relationship with all of our clients and providing them with the tools they need to succeed. To learn more about our PCD tools and services, give us a call at 440-892-7877.

Tungsten is one of the hardest metals you will find in nature. Also known as Wolfram, the rare chemical element exhibits a high density (19.25 g/cm3) as well as a high melting point (3422 °C/ 6192 °F). In its rare form, tungsten is hard to work with due to its brittleness, which can be changed when turned pure. Tungsten is often utilized to create hard alloys, such as high speed steel, to increase protection against abrasion as well as improve electrical conductivity.

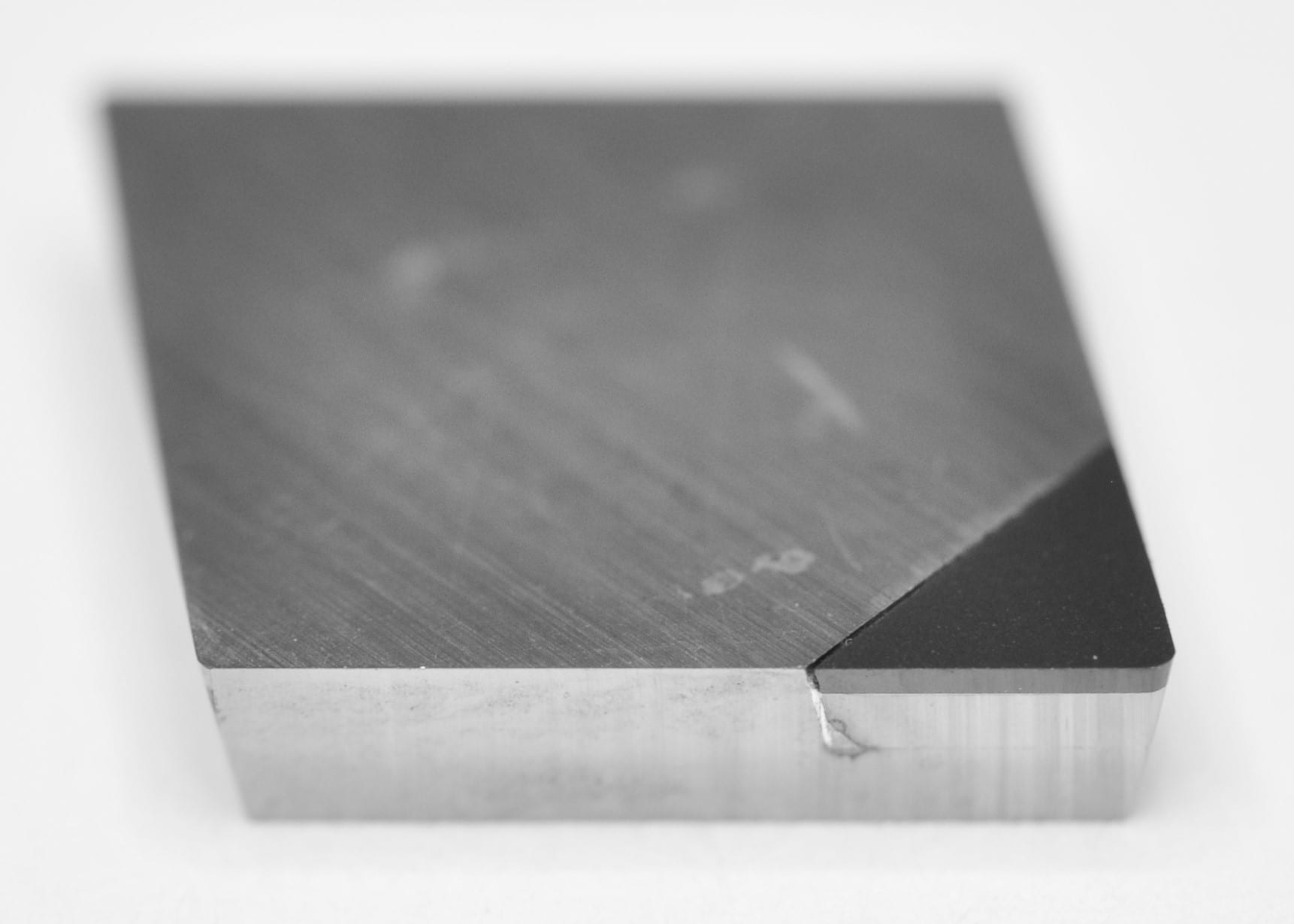

Steel is an alloy metal made of iron and other elements, such as carbon. It is the most used material in construction, mechanical engineering, and other industries. Due to the many variations and levels of quality steel can adopt, there is no uniform hardness value. There exist many techniques of tempering steel to improve the wear protection of steel, heat tolerance and protection against abrasion. Borocoat for example, optimizes the hardness of steel without making it brittle.

Chromium is an element often found in alloys, such as stainless steel. On the Mohs scale, which measures scratch resistance, it is found among the top. Chromium is valued for its high corrosion resistance as well as its hardness. Since it is easier to handle as well as more abundant than platinum group metals, chromium is a popular element used in alloys.

Our PCD tools are all about durability and excellent craftsmanship. Each tool is made by our awesome experts, always keeping your needs in mind.

We get it – when it comes to your tools, you want the best. That's why we have standard or custom PCD tooling solutions for you. And if you need a hand or have questions, our friendly customer service experts are here to make sure you're happy with everything.

Polycrystalline Diamond (PCD) tools have been a staple piece of the manufacturing industry for over 40 years. These diamond tools increase machine efficiency and durability with their abrasion-resistant material. No matter the size or complexity of your industry, PCD tools can help you save both time and money with their durability.

We pride ourselves on our commitment to your needs and create each tool specifically for you. If your tool needs any repairs and additional services, one of our customer service experts can easily go over your options to ensure your satisfaction.

PCD tools are composed of diamond particles that are infused into a metallic binder to create one of the most abrasion-resistant and durable materials in the metal cutting industry. You can rest assured that your PCD tool will be built to last and will cut your products with ease. PCD tools are also offered in a variety of forms and quality grades.

Metal is a genus that describes a number of different materials that are usually shiny, electrically and thermally conductive and, above all, hard. Metals are extremely diverse. In fact, more than 75 percent of the 118 elements on the periodic table are made of metals. So naturally, the question that poses itself to many is: “What are the hardest metals in the world?” In this article, we are looking at the many kinds of metals, regardless of whether they are elements, compounds or alloys, to find out what the strongest and hardest metals are. Our list is guided by the Brinell scale, which measures the indentation hardness of materials. It is important to note that there rarely is one unified value for one metal, as they tend to vary, depending on what alloys and compounds they are made up of.

Like Tungsten, Iridium is a chemical element that shows signs of high density and a tolerance of high temperatures. Iridium belongs to the platinum group of metals, resembling platinum in its look. However, iridium is hard to work with. Since it is very hard, iridium is also quite brittle, which is only aggravated by its very high melting point of over 2,000 °C. Iridium ranks among one of the rarest Elements on Earth’s surface, as well as one of the most corrosion-resistant elements.

0086-813-8127573

0086-813-8127573