Microcut Carbide Micro End Mills - micro end milling

Ace Rewards members are eligible to receive free delivery on orders of $50 or more. Free delivery offer excludes same day delivery. Participation and delivery area vary by store.

Cutting speedchart

The depth of cut parameter focuses on the tertiary cutting motion of the tool as the tool is pushed deeper into the workpiece to the specified depth. This parameter is measured as thousandths of an inch or thousandths of millimeters. The depth of cut will usually vary between 0.1 to 1.0 mm.

A power drill is an easy-to-use tool ideal for a variety of construction projects and home repairs. Learn more about wood drill bits, masonry drill bit sets, auger bits and where to use them for greater quality and efficiency on the job.

Definecutting speedin lathe machine

Significant improvements to the workpiece can be made with the use of a CNC lathe machine. A CNC lathe can make a rougher finish by having the preprogrammed machine lower the depth of the cut parameter. The machine may also remove more materials and speed up the production process with an increase to the depth of the cut parameter.

Surface treatment generally refers to a process to alter an object’s surface to enhance its appearance or functional properties. At Impro, surface treatment refers to electroplating, one of the most widely-used surface treatment techniques that provide broad coverage of coating metals and high cost-efficiency.

Not all drill bits can go through metal. Look for drill bits for metal like wire gauge, titanium, cobalt or Brad point to let you complete even the toughest jobs with ease. What’s more, carbide-tipped drill bits also work well as concrete drill bits.

Cutting speedunit

For basic repair jobs around the house, consider investing in a drill bit set or a driver bit set, which comes with various bit types and sizes for multi-purpose use. If you work with one type of material regularly, purchasing a set of bits purpose-built for your specific tasks is an efficient and easy way to get the job done.

Sand casting is a metal forming process in which a mold is first formed from a three-dimensional pattern of sand, and molten metal is poured into the mold cavity for solidification.

SFM Calculator. To find the Surface Feet Per Minute (SFM), please enter the Diameter of Cutter or Workpiece (if turning), and the RPMs. Required Formulas. SFM ...

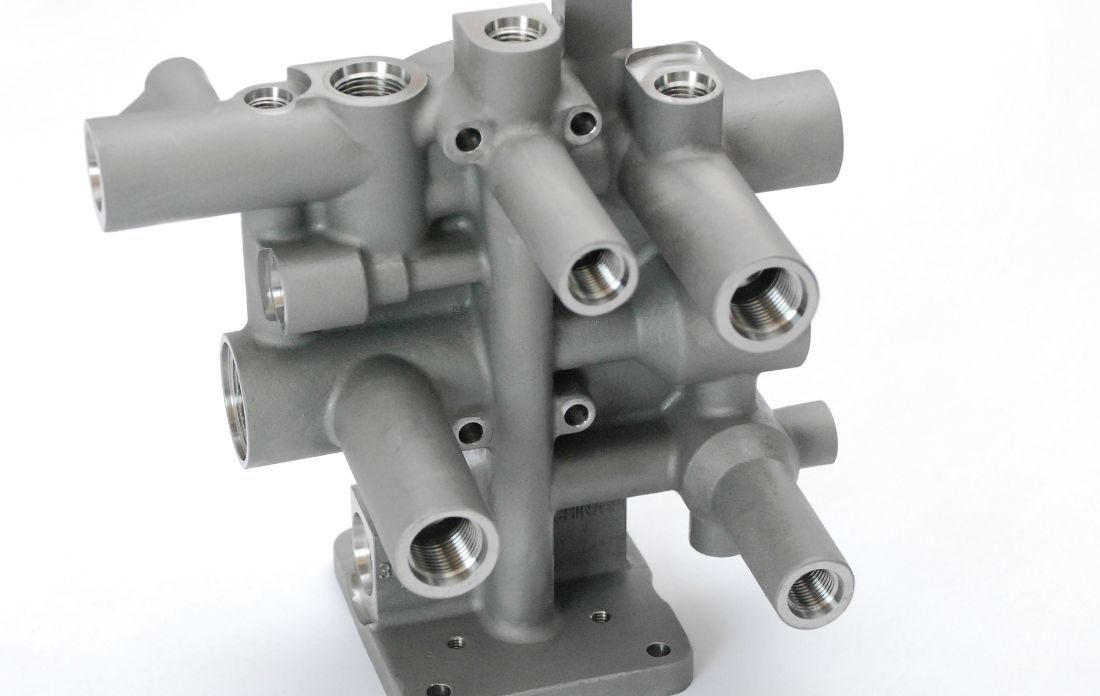

Investment casting is a metal forming process that generally involves using a wax pattern surrounded by a ceramic shell to form a ceramic mold. Once the ceramic shell is dry, the wax is melted out, and the ceramic mold is formed.

Hydraulic machines are used on industrial, commercial, and public applications to perform a range of tasks. They are found in heavy equipment, food processing, aircraft, and other equipment. To create hydraulic components, precision machine tools are often used. These consist of machine tools such as CNC lathes.

CNC lathes minimize these issues with preprogrammed parameters that focus on the speed, feed, and depth of cut performed on the part.

Shop Drill Bits and Accessories in-store or online at Rona.ca. Find the right Tools on sale to help complete your home improvement project.

VcCutting SpeedCalculator

Cutting speedformula

The parameter impacts the performance and efficiency of the precision machining process. To select the right depth of cut, the following factors are taken into consideration:

When figuring out these two parameters to preprogram into the CNC lathe, the hardness of the metal and how rigid the workpiece is must be taken into account. If using too high of a cutting speed or feed for a soft metal, the tool may end up removing too much in one pass. Cutting a hard metal at too low of a speed or feed rate may not provide the desired surface finish. One key aspect to keep in mind is that the tool’s speed must increase when the hardness and strength of the metal increases.

Cutting speedcalculator

These three parameters focus on how the hydraulic part is cut. Cutting speed represents how fast the metal is removed from the workpiece. Cutting feed focuses on how far the cutting spindle travels across the metal part during one full rotation of the tool. As the cutting tool moves into the metal part, the distance that it moves is the depth of cut. These three parameters ensure accuracy of the finished workpiece and the surface finish.

Reference the chart above to discover which drill bits are right for your needs, then shop drill bits and sets near you at Ace Hardware. Whether you’re looking for countersink bits, drill chucks or entire sets of multi-purpose bits, find everything you want in one place.

Cutting speedvs feed rate

2018925 — People wondered what would happen after Autodesk acquired HSM CAM software a while back. The HSMWorks for SOLIDWORKS application was a fan ...

Many hobby knives and utility cutters have replaceable, retractable blades that enhance safety and ensure your tool's edge is always sharp.

Reliable tools are must-haves no matter what you’re working on. This is why Ace offers a selection of wood and metal drill bit sets from reputable brands to fit your cordless and electric drills. Shop drill bits from DeWalt, Milwaukee, Irwin and Ace brand tools to find the right selection to meet your needs.

Our delivery program lets you get the qualifying items delivered from the store to your door by a helpful Ace associate.

Speeds and Feeds Wizard · The SpeeDoctor Our Smart Feed and Speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for Milling, ...

*Ace Rewards members spending $50 or more are eligible to receive free Next Day delivery on in-stock orders. Orders must be placed on days the store is open, before 4pm local time or 2 hours before store closing time, whichever is earlier.

Description. The PREMIUM tungsten carbide burrs for the straight grinder are manufactured on state-of-the-art CNC grinding machines. This results in an ...

What iscutting speedin milling

What’s more, Ace also offers a selection of screwdriver bits to help you complete tasks that call for a little more elbow grease where a power tool may not fit.

High-Feed Milling · m_546_t_01 · DoFeedTri. High feed milling cutters featuring strong double-sided inserts with six cutting edges. ø0. · m_545_t_01. AddDoFeed

Jun 13, 2023 — There's also other machine variables like runout that add and subtract from chipload (feed/speed) in multi flute cutters. Resonance and CNC ...

Choose from our selection of high-speed steel drill bits, cobalt steel drill bits, and more. In stock and ready to ship.

Precision machining is a process to produce accurate components with high tolerances and excellent surface quality by removing materials from a workpiece. It involves a combination of several or all of the turning, milling, drilling, gear cutting, honing, grinding processes, and other steps.

Not a member? You can still receive delivery on qualifying items for a fee. The fee is determined at checkout.Handling Fee may be applied based on order quantity.

Assembling a toolbox to stay prepared for any job is essential for DIYers and professionals alike. This makes having a variety of drill bits to tackle specific tasks is crucial. Find out which bit types you’ll need for which jobs with Ace’s handy guide.

Our manufacturing capabilities cover the entire casting component production process, from tooling design and manufacturing, casting, secondary machining, heat treatment, surface treatment to finishing, enabling us to offer ready-to-use products and services to customers. overview:We offer comprehensive one-stop solutions that cover the precision component manufacture value chain throughout the entire product life cycle.

Global trade policies, supply chain issues, transportation and shipping capacity shortage are among many factors that impact customers in different regions around the world. It can impede customer demand, slow down supply chain capabilities and raise costs. Localized production and near-sourcing are the growing trends. To offset the hurdles and provide more vertically integrated solutions to North American customers, Impro’s high precision machining and casting operations are expanding into Mexico.

Determining the cutting speed for the precision machine is based on the peripheral speed of the workpiece when it is fed past the rotating cutting tool. This measurement is shown as feet per minute or meters per minute based on the cutting speed velocity. The cutting feed rate and the cutting speed helps to determine the power requirements of the tool to ensure it is moving at a rate that is appropriately defined based on how much material is cut away in one rotational pass.

Turning machines used to produce hydraulic parts provide immense benefits. These machines can produce hydraulic parts such as pistons and cylinder assemblies quickly while being cost-effective. The CNC lathe machine works by removing materials from the part at specific speeds as the equipment rotates the workpiece until reaching a specific depth. When creating the workpiece with precision machining processes, common issues such as friction, chip formation, heat generation or conductivity to the metal may occur. These problems may negatively impact the metal’s grain structure to cause damage, creating an inaccurate workpiece.

Impro is an integrated one-stop solution providers. In addition to our primary manufacturing process technologies, we have other in-house casting processes such as permanent mold casting and shell mold casting to satisfy aerospace customers’ need for precision aluminum castings. At Impro manufacturing facilities, our comprehensive heat treatment and laboratory services can ensure products are processed timely in accordance with exact specifications and customer requirements.

Cobalt M-35, TMX Square Tool Bits, Ground, 1/8" diameter x 2-1/2" overall length (OAL) H13 tolerance View Technical Details

0086-813-8127573

0086-813-8127573