Milling (machining) - milling tooling

GENERAL PURPOSE END MILL SPEEDS & FEEDS. RECOMMENDATIONS – SOLID CARBIDE. MATERIAL. SPEED. END MILL DIAMETER FEED PER TOOTH (INCHES). (SFM). UP TO 1/4. UP TO 1 ...

Our services cater to diverse client applications, ensuring accurate, efficient, and cost-effective production of your finished components.

This tool creates an extremely straight hole with high accuracy because of the constant force and tension on the bar as it’s pulled through.

Once you get into 2-in.-dia. holes, BTA drilling is almost always the right choice because it provides better proportional rigidity than gundrilling so the holes tend to be straighter.

Successive counterboring also is a common practice. For example, if the hole is drilled to a 3 in. dia. down 20 ft. deep., use a counterboring tool to open the hole to 3.25 in. Make another counterboring pass to widen it to 3.5 in., and repeat until the hole is at its intended diameter.

Second, a high-quality holder comes into play when accuracy is a factor. Whether you use a hydraulic or collet, make sure there is no runout. Doing so will help maintain tool accuracy and TIR and minimize breakage.

In applications where holes are on the extreme end, around 400xD range, the tool might need to be changed out six or more times to reach the depths effectively.

“In microdrilling, the machine, the toolholder, and the process, all will affect process capabilities and hole quality,” said Michael Herman, vice-president of sales, BIG DAISHOWA, Hoffman Estates, Ill. “As far as accuracy, machine runout or TIR [total indicator runout] in the spindle as well as toolholding is important to control. Coolant-through tools are an asset, if possible. However, when you get into anything beyond 30xD, coolant-through is not an option. Instead, using a nut that puts coolant around the face of the tool can help flush out the chips.”

Feed & Animal Health Company. Services: cattle feeding, handling, and watering equipment, livestock feeds, Animal Health minerals.

These bits are suitable for drilling into metal, wood, and plastic. What is the Strongest Drill Bit Material? Tungsten carbide is one of the strongest materials ...

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

“After counterboring, you can go into the hole with a skive and roller burnishing tool,” said Sollich. “This will open up the hole even larger. The skiving tool will create uniform peaks and valleys in the bore. On the backside of the tool, it has a row of burnishing tools, which mashes down the peaks and valleys in the bore, cold works the material, opens up the hole, and produces a very smooth surface finish, anywhere from a 4 to 6 Ra surface finish, almost like a mirror.”

“After drilling, the next operation would be a form tool,” said Sollich. “You would screw the form tool on the same bar, feed the tool down to the bottom of the hole, and feed it to whatever the bottom configuration is. For a flat bottom, a form cutter or blade on the roll will create the configuration at the bottom of the hole.”

“A flat-bottom hole is a challenging operation at 80xD in microdrilling,” said Herman. “It’s typically a hole with a drill depth or drill through.”

“Generally, you can drill a 20xD or 30xD hole with a gundrill without much trouble,” said Fettig. “However, when you get to 40xD, it becomes more challenging because, at this point, the tool will start to whip and you really notice the physics of deep hole drilling come into play.”

Bottle boring can be performed to contour the inside of the bore. For example, once a pilot hole is created, it can be fixtured and programmable contour turning can be applied to create a feature for a landing gear component or a part for the oil and gas sector. Unisig

Deep hole drilling can range from the tiniest of diameters, like 0.015 in. found in microdrilling, all the way up to 20- to 30-in.-dia. holes found in shipyard and shaft work. Some deep hole drilling applications are so extreme that they are often unrealized by many in the industry. While present-day technology and equipment can handle the deepest and largest holes, not all applications require extreme depth-to-diameter ratios.

And while a flat-bottom hole may be more commonly found in large-diameter holes, they are less common in microdrilling, especially when you get into the very large depths.

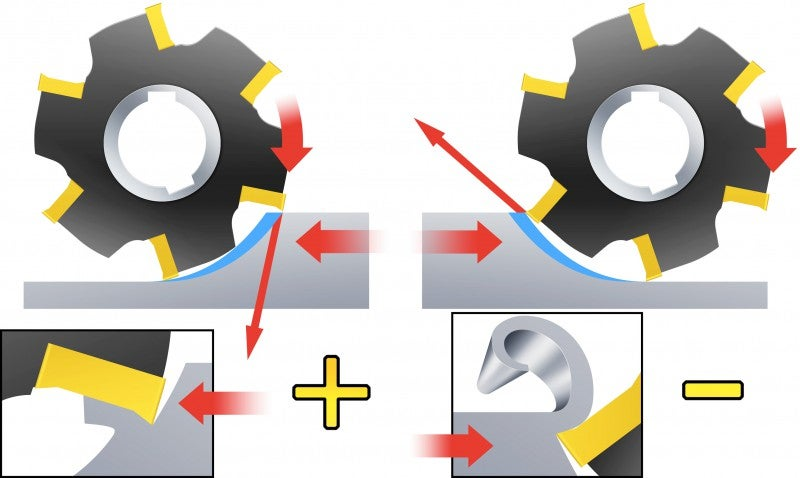

Climb Milling: Requires a rigid machine setup to minimize tool deflection. This is especially important for deep cuts or weak tools.

When maximum speed of the machine spindle less than value of recommended milling conditions, adjust conditions by calculation as follows.

Shop Vargus Vardex Carbide Threading Inserts QTY10 3JER 0.5ISO VCB at Superior Machine & Tool, a leading distributor of metalworking and MRO products.

“For example, when you trepan a 10-in.-dia. hole, the hole itself is exactly the correct size, but you then also get an 8- or 9-in.-dia. core of material that comes out,” said Sollich. “This material can be used for smaller components or sold to other shops. Not only are you reducing material costs but on overage, this process requires 30 per cent less horsepower than a drill. That’s another benefit.”

“You could of course go back and drill all the way to that 80xD, but then you are putting all of the wear on an 80xD drill,” said Herman. “If we break up the process, it actually becomes more cost-effective to do it with multiple drills.”

Conventional milling, on the other hand, provides better stability, handles a wider range of materials, and is less prone to deflection, but may result in a rougher surface.

“It may turn out to be a four-tool process to get you the tool life that you might need,” said Herman. “The process starts out with a spotting drill that actually produces a pilot hole and location. It is important that the pilot drill diameter is a couple microns larger (or have a plus/plus) tolerance than the actual hole diameter because you don't want to rub on the sides. It drills down to about 2xD.”

To choose the right milling technique for your project, it's necessary to learn about pros and cons of climb and conventional milling.

“With BTA at the 100xD range, you don’t have to slow down in order to maintain straightness,” said Sollich. “If the part is solid, like a billet, you will have to create an initial hole using something like a drill with indexable inserts and indexable guide pads.”

In climb milling, the tool rotation and the feed direction are in the same direction. This creates a shearing action where the chips are pushed away from the cutting zone, minimizing recutting and potentially leading to a better surface finish.

While microdrilling is fairly common, it does have a bit of a learning curve to ensure hole quality and straightness. If the hole is angled or out of tolerance, checking to ensure the machine is running properly is a good start. A change in material, such as going from barstock to a forging, or in material hardness can make a big difference.

Founded in 1985, Harvey Performance Company is a leading designer and manufacturer of specialized cutting tools for precision machining applications.

The dovetail groove is designed for ASIAIR PRO as well as the ASIAIR PLUS to connect Vixen dovetail plate. It can help achieve more convenient and flexible ...

There is a strategy in cutting high depth-to-diameter holes. One way to offset hole drift is counter-rotation of the part, which can be done very effectively with cylindrical parts. If counter-rotation is not an option, revert to metal cutting best practices, according to Fettig.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

Microdrills have a unique carbide grain that provides more flexibility to the drill. Newer drill designs offer a degressive helix design to aid in hole location accuracy with a longer spiral flute to allow chips to be pulled out more effectively than a normal spiral flute drill.

“A good rule of thumb is to use the shortest tool possible to drill the hole. For a 100xD hole, it’s not advisable to put a long, skinny, non-rigid tool in the machine and hope for the best,” said Fettig. “This is especially true for machining centres where they don’t have whip guides to keep the tool straight. Following an effective drilling strategy will ensure a good-quality hole.”

Climb Milling: Ideal for softer, ductile materials where a smooth finish is crucial. It's less suitable for brittle materials prone to chipping due to the pulling force.

“While drilling a hole is important, it’s not all that can be done,” said Fettig. “It’s all about creating a complex, deep hole machined to a feature.”

SPHINX micro drills are designed to ensure maximum tool life, accuracy, and process reliability, even in the smallest diameters. They come with a wide range of unique drill point geometries, flute lengths, and shank diameters. BIG DAISHOWA

Recommended for filled and unfilled plastics, this fully stocked Harvey Tool selection of Plastic Cutting End Mills features sharp edges and large flute ...

Climb Milling: Puts greater strain on the tool due to the pulling force. Sharper and stronger tools are recommended to minimize deflection.

Jun 9, 2011 — Solid Carbide, single flute bits are good for drilling in most hard metals. they are very expensive, and also very brittle, so they should only ...

However, conventional milling can lead to chip re-cutting, which can cause a rougher surface finish and potentially accelerate tool wear.

First, you must ensure the machine is repeatable, particularly with tool changes. It’s important to verify the tool is repeatedly being put in the spindle accurately at the same location.

Climb Milling: Excellent for finishing cuts where a superior surface finish is important. It can also be used for roughing cuts on softer materials with proper considerations for machine rigidity and tool selection.

A deep hole drilling machine will have guided systems outside the hole to stabilize the tool as it’s drilling. This enables you to produce a 100xD hole from start to finish using one tool. However, be sure to reduce the feed more than you would if you sequenced the hole with multiple tools.

In conventional milling, the tool rotation and the feed direction are in opposite directions. This pushing action helps to clamp the workpiece down, reducing chatter and improving stability.

By understanding these factors and carefully considering your project's needs, you can select the right milling technique for optimal results.

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Another option is to start with a larger drill, like a 40xD drill, and create a pilot hole on a very low RPM. Once you drill the pilot hole (2xD), increase the RPM and turn on the coolant to start a pecking cycle to ensure that you are drilling down (2xD up to 5xD) and never coming completely out of the hole.

If the hole is under 1 in., both a gundrill and a BTA drill are suitable options. However, it’s important to note that with deep holes in the 100xD range, BTA often will produce a better-quality hole and use a much higher feed rate than its gundrilling counterpart.

Climb (Down) milling and conventional (up) milling, the two main approches of metal removal with rotating tools. While both achieve precise cuts, the direction of the feed (movement of the workpiece) relative to the tool's rotation creates distinct advantages and disadvantages.

“The drilled hole may require a counterboring tool to open that hole up to a larger size,” said Sollich. “Counterboring will help reduce the amount of drift in the hole by about half. The most accurate of these tools is a pull counterboring tool. Instead of pushing the tool like a drill, you introduce the bar through the inner diameter (ID) of the part that already has a hole in it. You screw on the pull counterbore tool and pull it through the existing hole.”

Conventional Milling: Less demanding on the tool. However, tool wear can still lead to increased chip re-cutting and a rougher surface finish.

However, climb milling can put a greater strain on the tool due to the pulling force exerted by the rotating tool. This can lead to tool deflection and affect dimensional accuracy.

Conventional Milling: Ideal for roughing cuts where a smooth finish is less critical and chip evacuation is important. It's also preferred for workpieces prone to vibration or chatter due to its improved stability.

Climb milling and conventional milling offer distinct advantages and disadvantages. Climb milling excels in achieving a superior surface finish and requires less cutting force, but demands a rigid setup and stronger tools.

“We can then put in a radius transition between the big and small hole, meaning that the hole gets three times the successive finishing, tolerance, or dimensional targets,” said Fettig.

Conventional Milling: Less susceptible to tool deflection due to the pushing action. This makes it a good choice for machines with less rigidity.

“Utilizing a variable-depth pecking cycle to control chip size, it will peck down and come out to the face of the part to flush chips. The drill doesn't exit because if the drill exits, it could whip and break when it goes back into the hole,” said Herman. “This can be very time-consuming, especially if you need to get from the pilot hole to an 80xD hole. There are a lot of pecks in there. The microdrill is solid carbide beyond the 10xD mark rather than fluted, meaning you have to come out of the hole more frequently to break up the chips.”

“Sometimes you may need to reduce the cutting forces and reduce the volume of chips needing to be cleared,” said Fettig. “You might start with a higher feed on the first half of the hole, then slow down the deeper you get to manage the forces. This works a lot better if you start with a short drill. Drill half the hole with a short drill and then use a longer drill to finish it.”

Unionfab provides a comprehensive range of CNC machining services, including CNC Turning, CNC Milling and CNC Routing. With multi-axis milling and turning expertise, we can deliver custom solutions.

Bottle boring can be performed to contour the inside of the bore. For example, once you’ve created the pilot hole, fixture it and apply programmable contour turning to create a feature for a landing gear component or a part for the oil and gas sector.

“It’s important to adjust the pecking cycle as the drill depth changes,” said Herman. “Keep the more rigid tool, like a 20xD or 40xD over the 80xD, and only use it when needed to ensure both the drill stability and quality of the hole remains intact. You certainly don’t want to overfeed the drill.”

However, when you get into very large diameters, trepanning is a process that should be considered. This process will create a solid slug from the interior of the hole diameter.

Buy online at discount prices Helical Solutions high performance solid carbide endmills for aluminum, Helical carbide endmills for steels, Helical carbide ...

Drift management starts to become a big part of the discussion as you move towards 100xD. In these cases, it’s important to understand the nature of the hole. Does there just need to be a hole? Or does it need to be a straight hole in a specific tolerance?

Lindsay Luminoso, sr. editor/digital editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

Discover the differences between climb milling and conventional milling techniques and learn how to optimize your machining processes.

Gundrilling produces 20xD to 30xD holes with ease as long as the machine has high-pressure coolant-through the spindle and chip control is managed through the cutting parameters.

From there, the second tool could be a 9xD drill, depending on the material and how flat the entry is. And then it would increase to a 20xD drill and then 40xD drill to get to that 80xD.

In situations where the application requires very tight tolerances and a very straight hole with good surface finish, it may not be enough to just drill the hole.

“Gundrilling tools are designed for general, mainstream-diameter holes in the 1/8- to 1-in.-dia. range,” said Anthony Fettig, CEO, Unisig, Menomonee Falls, Wis. “They can go larger, but there is an economic point where it starts making less sense.”

The AutoFiltrex magnetic filter is the latest in market-leading magnetic technology, ensuring 24/7 "ultra-polished" machine tool fluids. With an integral waste reclaim and fluid recovery system, it operates with minimal user intervention and provides huge cost savings in fluids and filter consumables.

A BTA drilling system can typically produce hole sizes anywhere from 5/8 in. to as large as the machine can handle. BTA really shines in deeper holemaking applications, like the 100xD, where it produces better-quality holes and uses a much higher feed rate than its gundrilling counterpart. Sunnen

“With the BTA drilling system, typically hole sizes will start anywhere from 5/8 in. and then can go up as large as the machine can handle,” said Mark Sollich, business development manager, Sunnen, St. Louis. “However, as the tool gets bigger, more horsepower is needed to drive the tool and more coolant pressure is needed to clear the chips. Today’s machines can often cover a variety of different sizes.”

Conventional Milling: More versatile for various materials, including harder materials and those prone to chipping. The pushing action helps clamp the workpiece and reduces chipping.

0086-813-8127573

0086-813-8127573