Milling - Side Slotting - BT-SEMC - round insert milling cutter

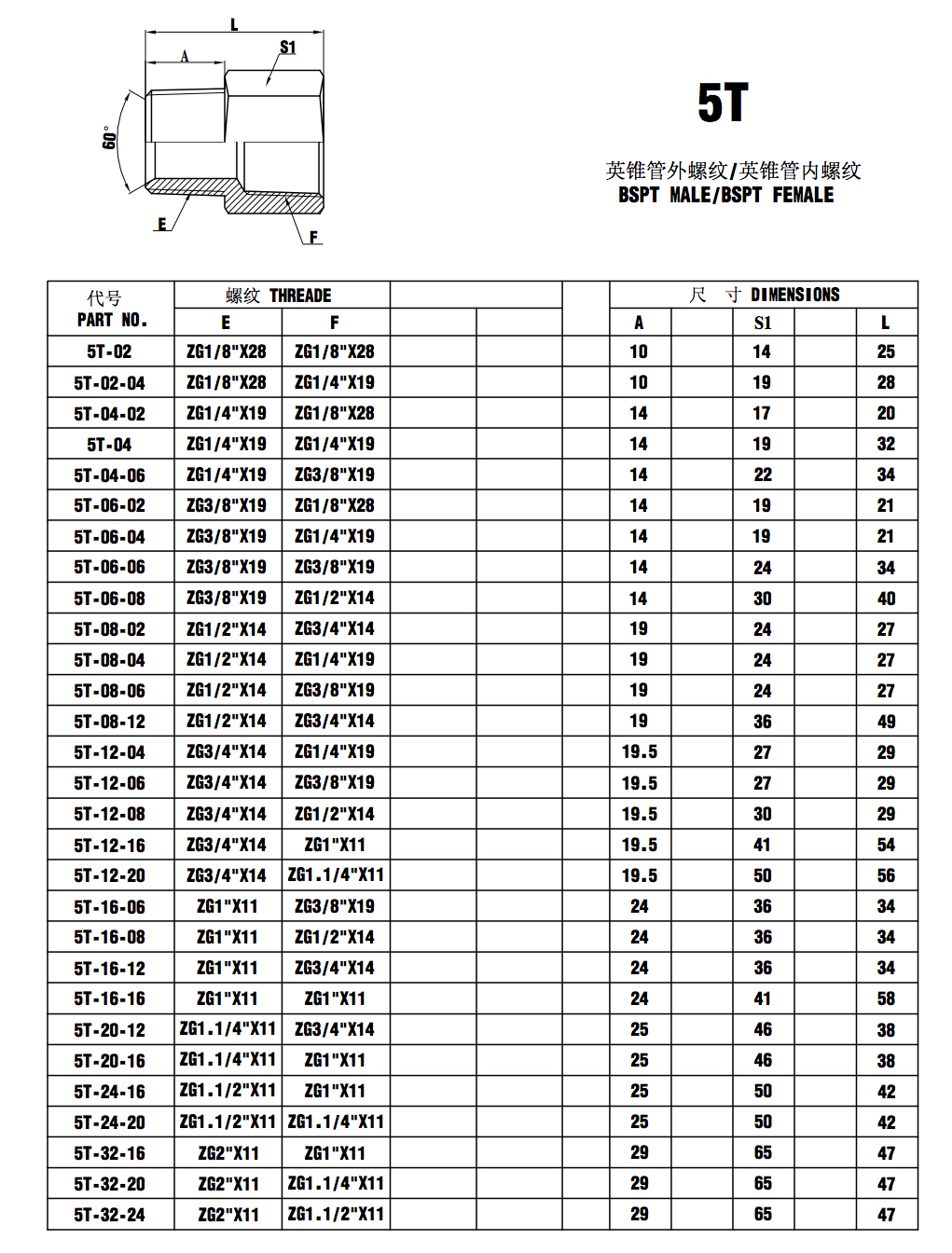

BSPT threads are widely used outside of the United States, especially in countries that follow British engineering standards. They are often seen in pressure systems and pressure calibration systems. Their ability to create a mechanical seal makes them suitable for many international applications.

May 21, 2023 — A lathe machine rotates a workpiece on an axis in order to perform a variety of functions, like cutting, facing, knurling and more.

Referring crossword puzzle answers · STYLE · LASER · STYLUS · STYLET · BURIN ...

When we talk about thread fittings like NPSM, NPTF, NPT, and BSPT, it's all about how they connect and seal pipes. These thread standards help us make sure things fit together right. Think of it like LEGO blocks – they need to match perfectly to stick together.

Key points about NPSM threads: - They are parallel, which means the diameter is consistent. - NPSM threads do not taper like NPT (National Pipe Tapered) threads. - They are used for making mechanical connections. - Sealing efficiency comes from gaskets, not the threads themselves.

When installing NPSM, NPTF, NPT, or BSPT fittings, it's essential to follow specific guidelines to ensure a leak-free connection. Here's a quick guide:

NPSM threads are often found in hydraulic systems where a leak-free seal is crucial. They work well in pressure systems like pressure calibration systems. The Female Pipe Swivel fittings are common with NPSM threads, allowing for easy installation in tight spaces.

lNPSM, or National Pipe Straight Mechanical, has straight pipe threads. It's good for making a mechanical connection that can be taken apart and put back together easily.

Aluminum speeds and feedscalculator

What is Hardenability? Hardenability is the ability of the steel to produce the appropriate hardness in relation to the amount of martensite when quenched for ...

Materials matter a lot. Most fittings are metal, like steel or brass, because they're strong. The making of these parts follows strict rules to ensure they're safe and will last a long time. This is about compliance – like following a recipe to bake a perfect cake every time.

Remember, getting the right fit is like choosing the right tool for the job. It's all about the details. Keep these tips in mind, and you'll be on your way to mastering thread fittings for leak-free connections.

NPSM threads are valued for their sealing efficiency when used with a proper mechanical seal. They are widely used in: - Fluid and gas transfer applications. - Industries that need a reliable mechanical connection.

When we talk about BSPT threads, we're diving into a world of pipes and connections that are essential for fluid and gas transfer. BSPT stands for British Standard Pipe Taper. It's a type of tapered thread used to make a leak-free seal. This standard is outlined in documents like BS 21 and ISO 7.

For a leak-free seal, parts like PTFE tape (Teflon), gaskets, or O-rings might be used with these threads. Tapered threads like NPT and BSPT can often seal on their own because of their shape – they get tighter and tighter as they're screwed in.

NPTF threads, also known as Dryseal American National Standard Taper Pipe Thread, follow the ANSI B1.20.3 standards. These threads are similar to NPT but are designed for a better seal. NPTF threads have a 60° flank angle and create a mechanical seal through an interference fit between the thread crests and roots. This means that the threads crush together to form a tight seal without needing extra sealants.

NPTF threads, also known as Dryseal American National Standard Taper Pipe Thread, are designed for a more secure, leak-free seal without the need for extra thread sealant. They're used in applications where a mechanical seal is crucial, like in fuel dispensing equipment.

The most important aspect of milling with end mills is to run the tool at the proper RPM (revolutions per minute or spindle speed) and IPM (inches per minute or feed rate). We have broken these recommendations down into material categories so you can make better decisions with how to productively run your end mills. Certain high performance mills have very specific running parameters relative to their material families. We have listed these also as individual recommendations by coating family. These documents are downloadable in pdf formats by clicking the links below.

Formula SAE is a student design competition which involves the departments of engineering of the Universities worldwide organized by SAE International.

BSPT threads are great for situations where you need a solid, leak-free seal without the complexity of other sealing methods. They're simpler to use than NPTF threads, which require precise pressure calibration to avoid issues like galling or damage from over-tightening.

Manufacturers also have to make sure their threads can handle the pressure they're supposed to without leaking or breaking. That's where quality assurance comes in.

NPT stands for National Pipe Tapered. It's a type of tapered thread used to join pipes and fittings. Here's what you need to know:

NPSM can sometimes be confused with NPTF (National Pipe Taper Fuel), also known as Dryseal American National Standard Taper Pipe Thread. Here's how they compare:

lNPSM vs. NPT: NPSM has straight pipe threads and requires a gasket or O-ring to create a leak-free connection. NPT's tapered threads form a seal by the threads themselves.

End Millspeeds and feedscalculator

Now, can you mix them up? Not really. Interchangeability isn't a game you want to play with thread fittings. Using NPT with NPTF can sometimes work, but it's not guaranteed to be a leak-free connection. And BSPT? It's a whole different story because of its unique thread angle and pitch. The most common mistake? Assuming they all fit together. Always check the standards, like ANSI/ASME B1.20.1 for NPT, to avoid leaks or damage.

lExperts suggest always following industry recommendations, like using ANSI/ASME B1.20.1 for NPT or ISO 7 for BSPT, to make sure everything fits just right.

Speeds and feedscalculator

lNPTF, also known as Dryseal American National Standard Taper Pipe Thread, is like NPT but designed to make an even tighter leak-free seal without needing extra stuff like PTFE tape.

Ideal use cases include: - Where a mechanical seal is more important than a thread seal. - Systems requiring frequent disassembly and reassembly. - When using a gasket or O-ring is preferred over thread sealant.

Screw Thread Size. Major Diameter. Minor. Diameter. Drill Size Decimal Equivalent. 1/4"-28. 0.25". 0.2062". 3. 0.213". 1/4"-20. 0.25". 0.1887". 7. 0.201". 12-32.

NPSM threads are a type of straight pipe threads. They follow ANSI/ASME B1.20.1 standards. These threads are designed for mechanical connection rather than making a seal. They have a 60° flank angle and are meant to be used with a gasket or O-ring to create a leak-free connection.

NPT threads are often found in general industrial applications. For example, a manufacturer of pressure calibration systems might use NPT fittings because of their compatibility with a wide range of equipment.

When working with BSPT connections, remember that they are not compatible with NPT or NPTF without adapters. Experts advise checking the thread standards like ANSI/ASME B1.20.1 for NPT, ANSI B1.20.3 for NPTF, or ISO 7 and BS 21 for BSPT to ensure proper fitting.

Aluminum speeds and feedschart

When we look at BSPT alongside other thread types like NPSM (National Pipe Straight Mechanical) and BSPP (British Standard Parallel Pipe), we see that BSPT is for creating a leak-free connection in tapered threads, while NPSM and BSPP are for straight pipe threads. BSPT threads make a mechanical connection without needing a bonded ring seal or O-ring, unlike BSPP which might need these for sealing.

lBSPT's Unique Position: BSPT threads are similar to NPT but have a different thread angle and pitch, making them not interchangeable with NPT fittings.

The speeds and feeds formulas are in the bottom of the charts below. If you follow these guidelines, you will have a much greater success rate in part programming, and you will be milling more efficiently.

lSealing efficiency is getting better. We're finding ways to make connections that are super tight without needing extra gaskets or O-rings.

Aluminum speeds and feedsfor milling

BSPT threads, with their 60° flank angle, are common in international applications. They're often chosen for their sealing efficiency in fluid and gas transfer systems.

We have created an excellent speeds and feeds calculator which incorporates these charts into the calculations. It generates ranges of SFM or SMM and allows you to decide what SFM is appropriate. It then automatically calculates the RPM. Then it gives you a range for FPT and allows you to decide what is appropriate. Then it automatically calculates the IPM or millimeters per minute (MMPM). Try it out! It is easy to understand.

lTolerances are the small differences allowed in the size and shape of threads. They're like the wiggle room in fitting pieces together.

CONTINENTAL INDUSTRIES - 166833658015, 0000-33-6580-15, 1-1/4 in. IPS ID Chamfer Tool with ID Gauge.

lNPTF threads are designed to provide a leak-free seal without the need for additional sealants. They create an interference fit between the thread crests and thread roots.

Aluminum speeds and feedstable

While NPT and NPTF threads look alike, their designs are different. NPT threads are designed under ANSI/ASME B1.20.1, and they may need PTFE tape or other sealants to ensure a leak-free connection. On the other hand, NPTF threads, following ANSI B1.20.3, are made to mesh tighter and form a seal without extra materials. They achieve this by a design that allows the thread crests and roots to squash together, creating a leak-free seal.

NPTF threads are often found in applications where a leak-free seal is essential, and no sealant is desired. However, while NPTF and NPT threads can sometimes be mixed, this isn't always safe or effective. NPTF threads can be screwed into NPT fittings, but the reverse may not seal properly because NPTF is designed for a closer fit. It's vital to check compatibility before mixing them to avoid issues like galling or improper sealing.

lNPTF threads are sometimes called Dryseal American National Standard Taper Pipe Thread because they're meant to seal without needing extra stuff like tape or paste.

Aluminum speeds and feedschart pdf

So, how do you pick the right one? Think about the job. For fluid and gas transfer, a leak-free seal is key. If you're working with pressure systems, BSPT might be the way to go. For applications that need a mechanical seal without sealant, NPTF is your friend. And for a mechanical connection that can be taken apart easily, NPSM could be the best choice.

NPSM threads, or National Pipe Straight Mechanical, are typically used with a female pipe swivel. A case study might involve a hydraulic system where NPSM fittings allow for easier assembly and maintenance.

Go for an interference fit—tight enough so the thread crests and roots press together, but not so tight that you strip the threads.

In the world of fuel and gas, NPTF threads are a go-to choice. They are designed to form a leak-free seal that is critical in pressure systems. These systems can't afford leaks, as even a small one could be dangerous. NPTF threads are used in pressure calibration systems and parts where maintaining the purity and integrity of the fluid or gas is crucial.

lNPT vs. NPTF: Both have a tapered pipe thread, but NPTF provides an interference fit between the thread crests and thread roots, eliminating the need for a sealant.

BSPT threads are unique. They have a 60° flank angle and are tapered, which means they get narrower as they go deeper. This is different from NPT threads, which are also tapered but have a 60° thread angle used in America, as defined by ANSI/ASME B1.20.1.

Industry professionals suggest using PTFE tape (Teflon) or a bonded ring seal with NPT fittings to ensure a leak-free seal. For NPTF, it's crucial to ensure proper engagement to take advantage of its dryseal function.

Remember, NPT is about creating a tapered pipe thread connection that's reliable and widely used. Whether you're working on a car or fixing a leak at home, knowing about NPT threads helps you make better connections.

Now, let's compare BSPT with NPTF. NPTF, or National Pipe Taper Fuel, often referred to as Dryseal American National Standard Taper Pipe Thread, as per ANSI B1.20.3, is designed for a tighter seal than NPT. It achieves this by creating an interference fit between the thread crests and thread roots. BSPT doesn't rely on this fit for sealing. Instead, it may need a thread sealant like PTFE tape (Teflon) or a gasket to prevent leaks.

Remember, getting the right fit means knowing your thread standards and choosing the right type for your pressure systems.

lQuality assurance means checking every part to make sure it meets the standards. It's like a teacher grading your homework to be sure you got the answers right.

Buy the latest smithy 3 in 1 lathe mill drill VEVOR CA offers the best smithy 3 in 1 lathe mill drill products online shopping.

Interactive and printable 29510 ZIP code maps, population demographics, Andrews SC real estate costs, rental prices, and home values.

When it comes to thread fittings used in pressure systems, the details matter. Let's look at how these threads are used in the real world.

Aluminum speeds and feedspdf

lBSPT, short for British Standard Pipe Taper, is similar to NPT but has a different thread angle and pitch. It's common in places that use British standards.

lNPTF, or National Pipe Taper Fuel, also known as Dryseal American National Standard Taper Pipe Thread, is designed to provide a tighter seal without the need for extra sealant.

When we talk about thread fittings like NPSM, NPTF, NPT, and BSPT, we're talking about the parts that help us join pipes and hoses together. These fittings make sure our water, gas, and other stuff move through pipes without leaking. Here's what we've learned:

When choosing the right cutting parameters to run, most people focus on the speed which relates to the machine RPM. This is a mistake! Focus on on the proper feed per tooth (FPT) first, and then adjust the speed. Often when a part is programmed, and is being proven out for production, the programmer will choose conservative parameters and encounter chatter. Chatter is nothing more that part vibration or noise, because the tool is not cutting properly. Usually, the first response is to slow the RPM and the chatter will go away. This often works, but this is unproductive. What has just happened is that by reducing the speed and keeping the feed constant, the FPT has increased. And most likely the FPT before was too low in the first place and that was what caused the chatter.

Note: These cutting feeds and speeds charts work with Accupro, Niagara, Data Flute, SPETool and all end mill brands. We will have all of Harvey Tool speeds and feed charts loaded soon.

Thread dimensions include the pitch (how far apart the threads are) and the angle of the threads. For example, BSPT threads have a 60° flank angle, which is part of what makes them unique.

lNPTF threads have a slightly different design that allows for a mechanical connection without the use of PTFE tape or other sealants, unlike NPT threads which often require them.

Are you troubled by not understanding NPSM, NPTF, NPT, and BSPT threads? This article will guide you through a detailed understanding of these threads, and teach you how to install them along with important considerations.

This HEHM 8-flute carbide end mill has a 1.0 in \ 1" cutting diameter, with a 1" weldon shank, 1-3/4" length of cut (LOC), 0.03" radius, ...

The American National Standards Institute (ANSI) sets rules for these threads in the U.S. For example, ANSI/ASME B1.20.1 is for NPT threads. They tell us how big the threads should be, how many there are in an inch (that's the thread count), and the shape they need to have.

Galling, or thread damage, is a risk with these fittings. To prevent it, never over-tighten and always follow the pressure systems' specifications.

Categories ... Based in the USA, CarbideDepot.com is the largest online supplier of carbide inserts and cutting tools. Choose from industry leaders Kennametal, ...

When it comes to thread fittings, it's like a puzzle. Each piece fits in a certain way. NPSM (National Pipe Straight Mechanical) threads are straight and designed for free-fitting mechanical joints. NPT (National Pipe Tapered) threads are tapered and make a tight seal by fitting deeper as they are screwed in. NPTF (National Pipe Taper Fuel), also known as Dryseal American National Standard Taper Pipe Thread, is similar to NPT but designed for a better seal without needing extra sealant. BSPT (British Standard Pipe Taper) threads, on the other hand, are used for making tight seals in pressure systems and have a 55° flank angle, different from the 60° angle used in NPT threads.

lNPT is a type of tapered thread used a lot in the USA. It makes a tight fit because the threads get smaller at one end, kind of like a cone.

0086-813-8127573

0086-813-8127573