Milling Machines - milling machine tooling

Pocket milling

Finally contour milling. Often done with a rounded tool called a ball end mill, contour milling can produce shapes with a three dimensional contour. Contouring can be used to produce tooling such as injection molds and forming dies.

The chamfer is in the drawing. Top edge of chamfer is selected, height is model top, bit size is correct 1/4" 90 degree, chamfer width 0, chamfer tip offset 0.1, chamfer clearance 0.

Pocketing can create round holes, or it can create rectangular or other shaped pockets. Notice that whenever interior corners are created with an end mill they will have a radius at least as large as half the end mill’s diameter.

Slab milling is similar to face milling in that it removes material to make the surface of a workpiece flat and or to reduce the overall thickness of a part.

Cncmachining profile

What is the width of the chamfer on your part? I believe the the offset must be greater than the width of the chamfer. I don’t model chamfers in my designs so I’m not sure if this helps. I do all my chamfers in the CAM operations.

3 days ago — Biggest flute top in the world, Andr 3000 album New Blue Sun joins a long history of flutes in top.

C and W have different shapes – the first trigonal and the second rhomboidal – but both, once placed on the respective tool, tackle the machining with the same ...

End milling operations include side milling, slotting, facing, or partial facing, pocketing, profiling, and contouring.

Machining profilepdf

In face milling the cutter is oriented perpendicular to the surface being cut. Face milling is used to create a broad, flat surface on a workpiece. Face mills often have a large diameter and many cutting teeth, however face milling can be done with a tool called a “fly cutter” that has a single cutting surface.

Speeds & Feeds for · 1 · 2 · 3 · 4 · 5 · Series · Style, Information. 205, Drill, View ...

... Insert. □ Threading Inserts Identification System (Partial Profile) J12~J15 ... TNN type threading insert is a negative insert and there is no relief angle ...

Machining profiletemplate

Slotting fully engages the end mill in the workpiece, and creates a slot with a rectangular or rounded profile depending on the end mill shape.

Attached are screenshots of a speed handle I made recently. I have modeled the chamfers that I wanted and successfully machined them using the following parameters using the 2D chamfer tool path. This is a 1/4" Diameter, 4 Flute chamfer tool with a .060" flat tip. The chamfer tip offset needs to be greater than the chamfer being cut. Feel free to message me if you need any further help with this.

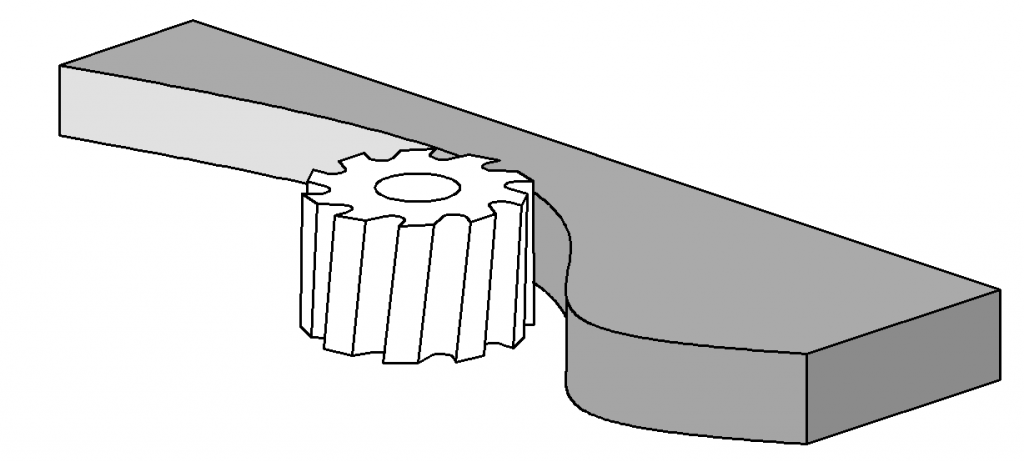

Peripheral milling is performed with the circumference of a round tool. Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations.

Jan 18, 2021 — CCMT32.51 is a great all around insert. CCMT32.52 is more of a roughing insert with a wider nose radius, and CCMT32.50 is better for fine ...

End milling

Machining profileexample

Profiling is done on the perimeter of a workpiece and can produce nearly any shape that has interior radii at least as large as that of the cutter.

Apr 16, 2024 — Nail Structure and anatomy. basic parts of a human nail: hyponychium, Lunula, Cuticle, Matrix, and Nail bed. cross section of finger. What Are ...

Cermet has grown to become a major supplier of these materials serving customers throughout the world with sales and applications support in the U.S., Asia, and ...

Profilemilling cutter

I have had good luck using 2D Contour on the bottom edge if the model has the chamfers, or 2D Chamfer if I didn’t model them.

Side milling is probably the most common end milling operation. In side milling the tool is engaged both axially and radially. The amount of axial engagement is known as the “stepover” and is often specified in percent of tool diameter.

Find here online price details of companies selling Cutting Machine. Get info of suppliers, manufacturers, exporters, traders of Cutting Machine for buying ...

Profilemilling asphalt

Platinum is a member of the platinum group of elements and group 10 of the periodic table of elements. It has six naturally occurring isotopes. It is one of the ...

End milling is probably the most common class of operations performed on milling machines. End mills are cylindrical cutters that normally have two or more cutting edges on both the periphery and end of the tool.

I agree. I don’t even put them in the drawing. I have had a similar problem also making threads in large bronze prop nuts.

Because profile milling and contour milling require control in more than one axis at a time, they are generally done on CNC mills today, but were historically done with tracing mills that reproduced contours and profiles from a master pattern.

I’ve not seen any good solutions for modeled chamfers. You’d think it would be the easiest way to tell fusion what you want. I just stopped modeling them based on everything I read and suggestions from others. Way easier to program without them currently, but I’d much prefer to include them in the model.

Facing or partial facing is done more efficiently with other types of tools such as fly cutters or face mills, but it can be done with an end mill.

I am having a problem with chamfering a part I have cut. The toolpath and simulation looks to be correct, however the bit does not touch the part. I have tried everything I can think of.

On a mill one (speed) is a distance the circumference of your tool does per unit around the tool axis and the other (feed) is the distance the ...

I believe NYCNC has a great tutorial on this topic. I have no idea if it still valid for this build of fusion 360. They do it modeled and not modeled. I can see benefits to them both.

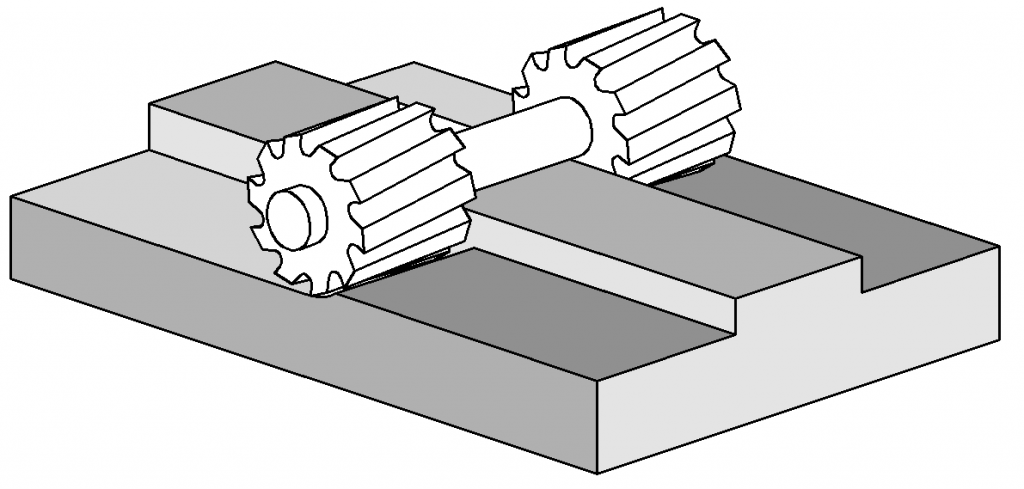

Straddle milling may use two or more cutters on the same arbor to create a rectangular pad of a desired width. Using two or more cutters simultaneously in this way is known as gang milling. Gang milling can be used to create more complex shapes, such as v-ways and cooling fins.

Milling machines can be used to perform a wide variety of machining operations. While milling machines can be used to perform holemaking and specialized machining operations, they usually perform tasks that fall into one of these three categories: face milling, peripheral milling, and end milling. Let’s look at each of these in a little more detail.

0086-813-8127573

0086-813-8127573