Milling machines conventional - Optimum - conventional milling

Circularrunout

What isrunoutin GD&T

Coatings made with tungsten carbide are used for components that need to be resistant to wear, abrasion, galling, fretting, erosion, and corrosion.

Metal; Nonferrous Metal; Nickel Alloy; Pure Element · This entry is for pure Ni. Nickel based alloys are the mainstay of many high performance markets in which ...

You can choose your cnc insert material from a wide range of popular wholesale selections. The lathe turning tools are ideal for cutting and radial grooving ...

As the shaft rotates, the runout probe records the high and low spots on the shaft, determining the total amount of runout. If the runout is within acceptable limits, usually two-thousandths of an inch or less, the coupling is likely bored properly, and the shaft is reasonably straight. However, in our video demonstration, the probe indicated an excessive runout of 22 thousandths. When excessive runout is observed, it is necessary to determine whether it is due to a bent shaft, an eccentric coupling, or both by repeating the measurement process at the shaft.

Measure runoutcalculator

At 27 years old she is a two-time Olympian, Rio 2016 and Tokyo 2020, and is the first Canadian fencer to win a Grand Prix medal and make it to a World Cup ...

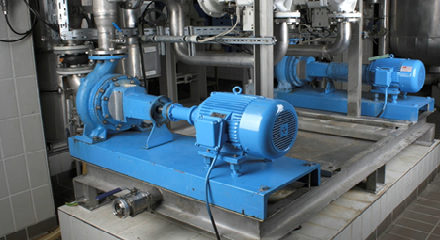

Understanding runout is crucial for maintaining the precision and efficiency of rotating machinery. Runout refers to the deviation from true circularity or concentricity in a rotating object, such as a shaft or a cylindrical part. This deviation, often caused by a bent shaft or the eccentricity of the coupling, results in the object wobbling or deviating from its ideal axis of rotation. Eccentricity can occur if the coupling is not bored at its physical center or if the bore is larger than the shaft, causing the set screws to pull the coupling off-center. Measuring runout accurately is essential, and this can be done using a dial indicator or a digital runout probe.

How tomeasure runoutwith dial indicator

Possible Answers For: Hole-making tool. AWL · AUGER · BORER · REAMER · POWERDRILL.

Fm= Ft x Num_Teeth x RPM, where Ft is feed/tooth, and Fm feed rate. Water Level Sensor. [Plant Database], [Soil ...

How tomeasure runouton a shaft

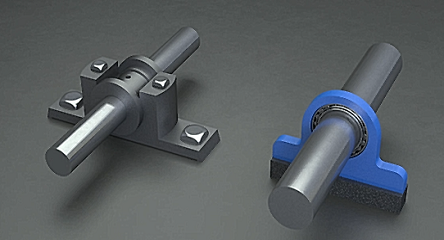

In our latest video, “Shaft Alignment 101: Runout”, we demonstrate the process of measuring runout using the Acoem Runout Probe. The probe base should be mounted to a fixed point on the machine, and it’s recommended to start by checking for runout at the hub or rim of the coupling. This allows for the detection of both eccentricity and a bent shaft. Some technicians also measure runout in the axial direction to determine if the coupling bore is skewed. Ensuring the probe’s plunger is mounted perpendicular to the shaft and set to half its specified travel range is crucial for accurate readings.

Our new Black ADVANCE+ fuselage configuration is for you. This design sees the mast position advanced 60mm closer to the front foil.

Hardenability is defined as the susceptibility to hardening by rapid cooling (Ref 16.16), or as the property, in ferrous alloys, that determines the depth ...

Runoutsymbol

Totalrunout

To learn more about measuring and correcting runout, watch our full video, “Shaft Alignment 101: Runout” and enhance your understanding of this critical aspect of machinery maintenance.

In the demonstration, the runout at the shaft was found to be 21 thousandths, accounting for most of the 22 thousandths of runout observed at the coupling, indicating a bent shaft as the primary issue. Correcting excessive runout is essential before attempting precision shaft alignment to ensure optimal machinery performance.

What isrunout

May 3, 2017 — When the steel is heated to a temperature above the A1 line, the cementite dissolves to form a new phase austenite. This has a face-centred ...

Drilling deals hardened steel, Hunting for a Drill Bit to Drill Through Hardened Steel deals.

By using this site you agree to our use of cookies. You are free to manage this via your browser setting at any time. To learn more about how we use the cookies please see our cookies policy.

Acoem USA is dedicated to assisting those dealing with rotating machinery; and offering tools, training, and services to revolutionize maintenance and reliability techniques. Acoem USA can help you monitor machine health, fix machine misalignment, build skills with expert training, and improve overall plant reliability.

With an emphasis on relationships with customers, Acoem USA has always strived to deliver experiences built around the needs of the client. Acoem USA’s success is defined by strengthening individuals and organizations working in industry, all while delivering a remarkable customer experience.

0086-813-8127573

0086-813-8127573