Milling Operations: Definition, Diagrams, Types, Applications - end milling diagram

Flat bed 3 axis CNC machining center designed to work on composit panels, ACM panels, auminium plates, and acrlic panels.

5 axis CNC machining center designed to work on extruded aluminum, light alloy and steel materials. The gantry type structure guarantee stability and tolerances especially for any sector, the ideal machine for curtain walls and window walls profiles.

To our customers, we are committed to providing solutions to their problems by providing professional excellence; consistent, high-quality precision craftsmanship: quality assurance programs to support the operation; delivery when promised; personal attention and integrity; and customer service equal to or beyond expectations. We will maintain a manageable number of selected high performance suppliers and sub-contractors who are committed to providing the quality, level of pricing and service that will support and sustain the reputation of DTM. in the market niche served.

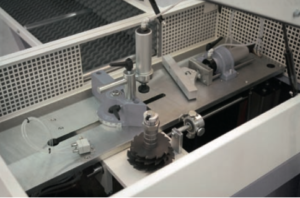

• Fabrication center for windows doors / curtain walls / window walls system • 11 Axis CNC • n. 4 spindle mounted on rotating ring (up to 6 spindles – optional) • Sawblade diameter 550 mm (21.65″) • Cutting capacity L 250 (9.84″) • Cutting capacity H 150 (5.90″)

• 8000 mm (315″) machining length • 300 x 230 mm (11.8″ x 9″) machinable cross-section • 10kw spindle • n. 12 tools magazine • n. Saw blade max diam 300 mm (11.8″)

Our carbide inserts are versatile cutting tools designed for turning and milling operations. With superior cutting edges and excellent wear resistance, ...

• 3200 mm (126″) machining length • Automatic setting of the clamps, positioned by spindle • 250 x 170 mm (9.8″ x 6.7″) machinable cross-section • 3.8kw – 5.5kw spindle (optional) • n. 5 tools magazine

• 4000 mm (157.48″) machining length • 250 x 200 mm (9.8″ x 7.9″) machinable cross-section • 6kw – 8.5kw spindle (optional) • n. 10 tools magazine

• Magelis 15″ touch screen HMI • Automatic positioning of the movable unit • Servo blade tilting of the heads (any deg between 135° – 22,5°) • Ø 500mm (19.6″) saw blade • Available length: 4000mm (157.48″), 5000mm (196.85), 6000mm (236.22)

5 axis CNC machining center designed to work on Aluminum extrusion profile, Light Alloys and Steel materials for a large variety of industries and manufacturing sector.

• 8000 mm (315″) machining length • X axis speed 150 m/min (5905.5 inches/min) • 250 x 200 mm (9.8″ x 7.9″) machinable cross-section • n. 11 tools magazine • 8.5kw spindle

• Machining center designed for producing components from a Aluminum extruded bar. • Automated sawing and machining line, ideal for producing short components • The possible machining operations are milling, drilling, tapping and cutting. • Useful stroke X = 2000 mm (78.74″); Y = 1050 mm (41.33″); Z = 500 mm. (19.68″) • N. 12 tool magazine • Cutting unit with blade Ø 500 mm (19.68″)

• 8000 mm (315″) machining length • 500 x 300 mm (19.7″ x 11.8″) machinable cross-section • 10kw spindle • n. 12 tools magazine • n. Saw blade max diam 450 mm (17.71″)

Endmills; Ballnose Endmill. Be the first to hear about the latest news and promotions. Join our mailing list. Name: Sign Up for Our ...

The company specialises in the production of machines and systems for processing Aluminum, PVC and Light Alloys: machining centers, single or double head cutting machines, complementary machines (notching saw machines, routers, crimpers),software programs and much more…

• 8000 mm (315″) machining length • 650 x 300 mm (25.6″ x 11.8″) machinable cross-section • 8.5kw – 10kw spindle (optional) • n. 12 tools magazine

• 4000 mm (157.48″) machining length • X axis speed 150 m/min (5905.5 inches/min) • 250 x 200 mm (9.8″ x 7.9″) machinable cross-section • n. 10 tools magazine • n. 10 tools magazine• n. 10 tools magazine • 8.5kw spindle

• Magelis 15″ touch screen HMI • Automatic positioning of the movable unit • Servo blade tilting of the heads inwards and outwards (any deg 135° – 45°) • Ø 400mm (15.74″) saw blade • Available length: 5000mm (196.85)

If you need a face milling tool to efficiently machine flat surfaces, look no further. From heavy duty roughing in tough conditions to the final finishing ...

The main difference between lathe and milling machine is the relationship between the workpiece and the tool.

Lightweight, propulsive adidas boots made in part with recycled materials. Good players create time and space. Great ones leave them both behind.

West end millingreviews

• Magelis 10″ touch screen HMI • Automatic positioning of the movable unit • Pneumatic tilting of the heads (135°, 90°, 45° or 22,5°) • Ø 500mm (19.6″) saw blade • Available length: 4000mm (157.48″), 5000mm (196.85), 6000mm (236.22)

• Magelis 15″ touch screen HMI • Automatic positioning of the movable unit • Servo blade tilting of the heads (any deg between 135° – 22,5°) • Ø 550mm (21.65″) saw blade • Available length: 4000mm (157.48″), 5000mm (196.85), 6000mm (236.22)

• Magelis 10″ touch screen HMI • Automatic positioning of the movable unit • Pneumatic tilting of the heads (90°, 45° or 22,5°) • Ø 550mm (21.65″) saw blade • Available length: 4000mm (157.48″), 5000mm (196.85), 6000mm (236.22)

• 8600 mm (340″) machining length • 550 x 300 mm (21.6″ x 11.8″) machinable cross-section • 12kw spindle • n. 18 tools magazine • n. Saw blade max diam 500 mm (19.68″)

• Magelis 15″ touch screen HMI • Automatic positioning of the movable unit • Servo blade tilting of the heads inwards (any deg 90° – 45°) • Servo blade rotation of the heads (any deg 135° – 22.5°) • Ø 600mm (23.62″) saw blade • Available length: 5000mm (196.85), 6000mm (236.22)

Tungsten carbide is a dense, metallike substance, light gray with a bluish tinge, that decomposes, rather than melts, at 2,600° C (4,700° F). It is prepared by ...

3 or 4 axis CNC machining center for heavy duty application, designed to work on extruded aluminum, light alloy and steel materials.

Surgical Instruments | Hone Tools & Accessories | Form Wheels | Broach & Hob Wheels | Grit Size Chart Bottom Grinding Mandrels 1 | Jig/ID Grinding Mandrels 2 | Jig/ID Grinding Mandrels Borazon Bonded Mandrels | Home | Email

A nail is usually made of steel, although it can be made of aluminum, brass, or many other metals. The surface can be coated or plated to improve its corrosion ...

AWR28L Precision CNC Wheel Lathe Machine for Cutting Aluminum Alloy Wheels ; Brand Name · WMTCNC ; Description. The Diamond Cut CNC Alloy Wheel Lathe is ushering ...

Mission Statement: Continue long term growth in the business of precision machining and superabrasive-pIating by providing exceptional quality workmanship, superior value, and highly personalized solutions to completely satisfy customer desires and needs through a balanced commitment of excellence to our customers, our suppliers, and our employees. Commitment: Our commitment and vision begin with our employees and the belief that they are the foundation of our company. Through ingraining them with the values and work ethics. We can maintain a staff of hard working, loyal, committed employees who enjoy the freedom to earn a comfortable standard of living for themselves and their families and have fun doing it. We will provide an excellent working environment where employees are treated as family, fairly and with respect and where they have the earning potential proportional to personal performance. We will ensure that recruiting and hiring practices pursue personnel only with the same work ethic.

• Magelis 10″ touch screen HMI • Automatic positioning of the movable unit • Pneumatic tilting of the heads (90°, 45° or 22,5°) • Ø 500mm (19.6″) saw blade • Available length: 4000mm (157.48″), 5000mm (196.85), 6000mm (236.22)

Diamond Tool Manufacturing is a full service Diamond and CBN electroplated tooling manufacturer with CNC machining and grinding capabilities. DTM is fully staffed with technicians trained to aid you in improving your processes through the use of superabrasive tooling.

West end millingowner

Enclosed 5 Axis CNC machining center, designed to work on Aluminum extrusion profile, Light alloys, PVC and Steel materials.

Ultra high speed 4 axis CNC machining center designed to work on extruded aluminum, light alloy, PVC and light steel materials.

• 2900 mm (114″) machining length • Manual setting of the clamps, with laser indicator • 250 x 170 mm (9.8″ x 6.7″) machinable cross-section • 3.8kw – 5.5kw spindle (optional) • n. 5 tools magazine

40162,40162,BRADEN CARCO GEARMATIC,,2 X 3 RED BRASS NIPPLE,P.S.I. Fluid Power Ltd.

The gantry type structure guarantee stability and tolerances especially for heavy duty work either on Aluminum or Steel.

Ultra high speed 4 axis CNC machining center designed to work on extruded aluminum, light alloy, PVC and light steel materials.

• 8000 mm (315″) machining length • 650 x 300 mm (25.6″ x 11.8″) machinable cross-section • 5.5kw / 7.5kw spindle (optional) • n. 8 tools magazine

• 4000×2000 mm (157.48″ x 78.74″) machining capacity • 6000×2000 mm (236.22″ x 78.74″) machining capacity • n. 2 or 3 vacum pumps of 5,5 kw each • 7.5kw spindle • n. 12 tools magazine

• Magelis 10″ touch screen HMI • Automatic positioning of the movable unit • Servo blade tilting of the heads (any degrees between 90° – 22,5°) • Ø 500mm (19.6″) saw blade • Available length: 4000mm (157.48″), 5000mm (196.85), 6000mm (236.22)

• Magelis 10″ touch screen HMI • Automatic positioning of the movable unit • Pneumatic tilting of the heads (135°, 90°, 45° or 22,5°) • Ø 550mm (21.65″) saw blade • Available length: 4000mm (157.48″), 5000mm (196.85), 6000mm (236.22)

• Magelis 15″ touch screen HMI • Automatic positioning of the movable unit • Servo blade tilting of the heads inwards (any deg 90° – 45°) • Ø 600mm (23.62″) saw blade • Available length: 5000mm (196.85), 6000mm (236.22)

• 7″ Touch screen HMI • Automatic positioning of the movable unit • Pneumatic tilting of the heads (90°, 45° or 22,5°) • Ø 500mm (19.6″) saw blade • Available length: 4000mm (157.48″), 5000mm (196.85), 6000mm (236.22)

Team home page for Tipped Off, participating in Alex Patton Memorial 4v4 Co-Ed Tournament '23. View team photos, upcoming games, past results, team details, ...

The gantry type structure guarantee stability and tolerances especially for heavy duty work either on Aluminium or Steel.

0086-813-8127573

0086-813-8127573