Milling Operations: Definition, Diagrams, Types, Applications - milling cutter diagram

Graphite machiningCompanies

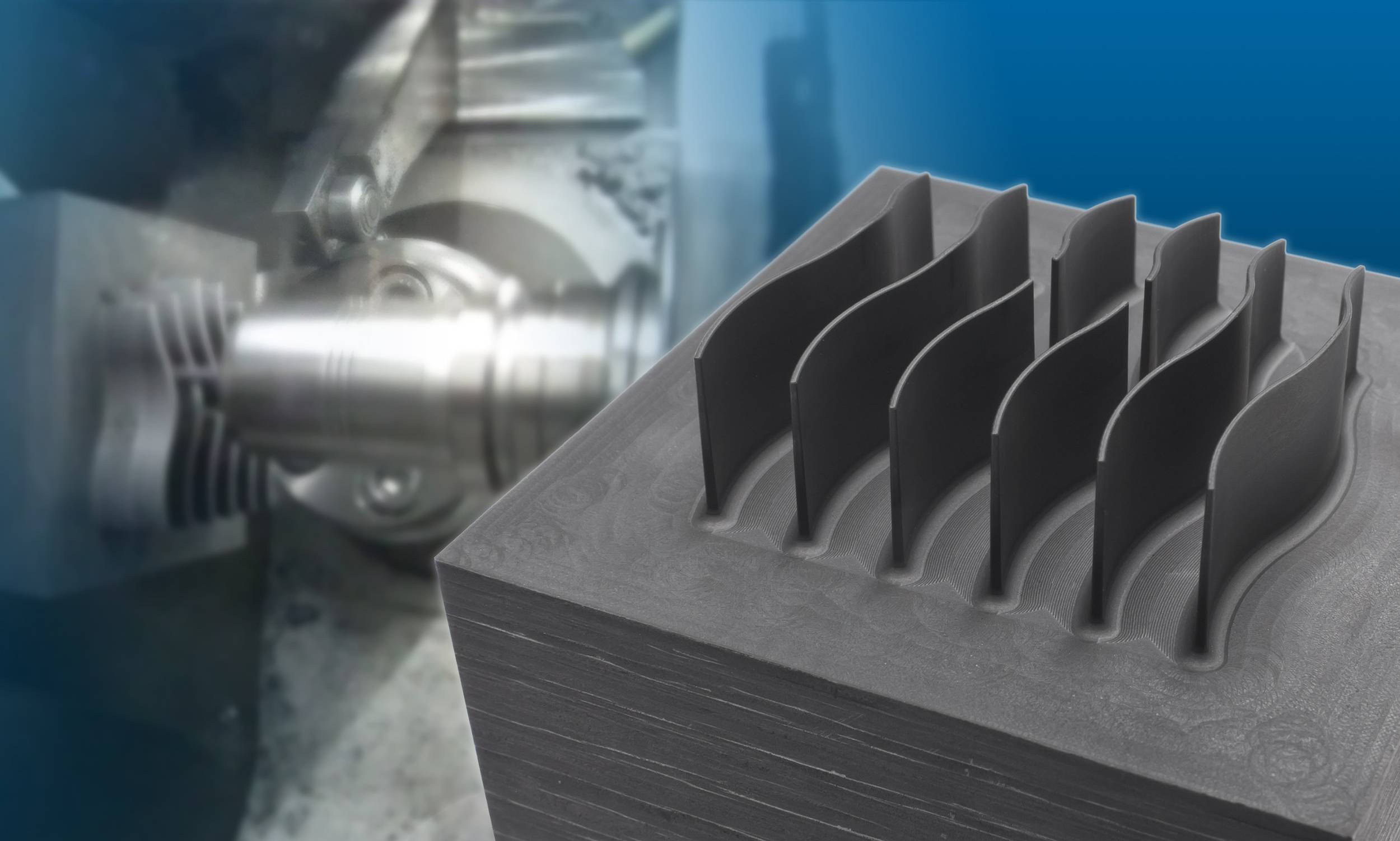

Among other CNC milling machines, DATRON's C5 5-axis milling machine enables the precise machining of graphite electrodes. By combining advanced technology and expert know-how, we ensure that you get the best possible solutions for your graphite machining needs.

Machining graphitefeeds and speeds

Graphitemilling machine

If you have any questions or would like to know more about our machines for graphite processing, please do not hesitate to contact me.

Graphite machiningnear me

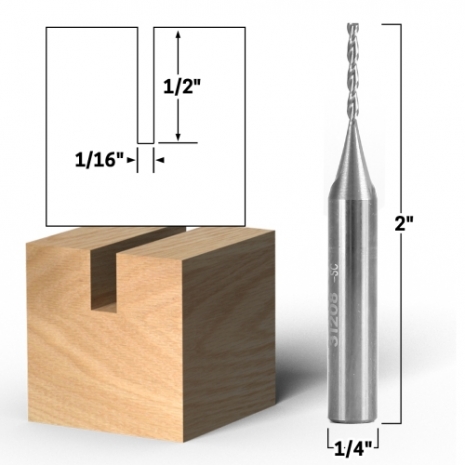

Instructions: Slowly dial up the RPMs on your router to the recommended maximum. Then, dial back if needed to find the “sweet spot”. The sweet spot is the speed at which the least resonant vibration is present. If the sweet spot cannot be achieved within 5,000 RPMs of the max, check the collet for residue or other debris and start over.

Warning: Make sure the router bit is properly fastened and tightened in the router’s collet and the bit can rotate freely without any obstructions.

DATRON's strengths in working with graphite are groundbreaking and make the company a leading innovator in the industry. Let us convince you of the technical features and advantages:

The production of graphite electrodes offers a clear advantage over the production of copper electrodes, particularly due to the cost sensitivity of the markets. DATRON has perfected the processing of graphite and graphite composites and offers the right technology for this. The advantages of graphite electrodes lie not only in the cost savings, but also in their higher machining speed, lower wear rate and excellent thermal properties, which are crucial for many companies and their industrial applications.

0086-813-8127573

0086-813-8127573