Milling Speed and Feed Calculator - cnc feed speed calculator

Saws on Skates® is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. Read the full disclosure here.

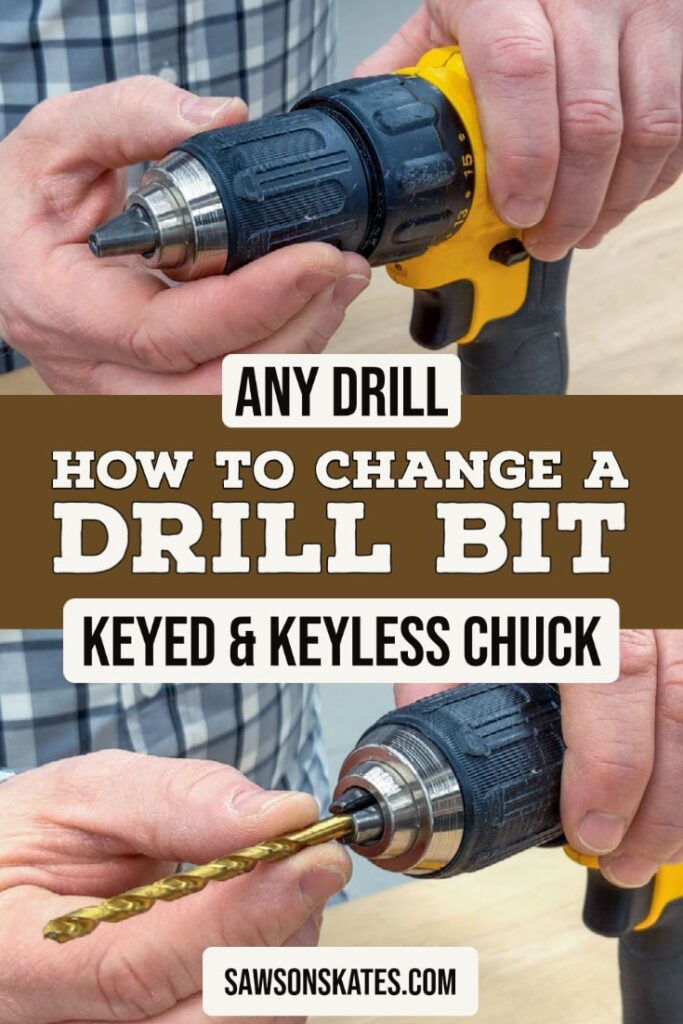

Before you change a bit, disconnect your drill’s power by either removing the battery or unplugging it from the electrical outlet.

To use a keyed chuck, you insert the bit making sure it’s centered in the jaws. Then you turn the key clockwise to tighten the chuck and hold the bit in place.

Products & Services > Milling Cutters ... Guhring is somewhat unique amongst carbide end mill manufacturers in that it produces its own carbide rod which is the ...

Aug 13, 2021 — The base principle of the process involves the thermal breaking of the heavier hydrocarbon chains under high pressure to obtain lighter and shorter chain ...

TRUMPF slitting shears are used in a variety of industries, for example in drywall construction, façade construction, ventilation and air duct construction.

Power drills come with two types of chuck, keyed or keyless, while impact drivers have a different kind of chuck called a collet.

Grasp the rear portion of the two-part chuck (near the drill’s body) and rotate the front piece counterclockwise with your other hand to open the jaws.

Unlike drills, impact drivers don’t have adjustable jaws; instead, they have a collet, a sleeve, or a band that clamps the bit in place.

Once you’ve positioned the bit correctly, insert the chuck key into the side of the chuck and rotate it clockwise to close the jaws tightly around the bit.

To prevent potential accidents, disconnect your drill’s power source by removing the battery or unplugging it from the electrical outlet before changing the bit.

My corded drill has a two-part keyless chuck. To use this style, you hold the rear piece of the chuck closest to the drill’s body and turn the front part. Turning clockwise tightens the chuck while turning clockwise loosens it.

If your chuck’s jaws are closed, not opened wide enough to insert a new bit, or if there’s a bit already installed, you’ll need to open them up.

Adds premier R&R brand in Northeast in Harvey Windows ... Sandy East, Vice President, Customer Service, to Receive Women in Manufacturing STEP Ahead Award for ...

Occasionally drill bits can become wedged between two of the jaws, causing it to spin off-center and making it impossible to drill a hole or drive a screw. If this happens, open the chuck wider and center the bit in all three jaws.

You can remove the bit by reversing these steps. Please use caution when removing drill bits as they become hot with use.

A keyed chuck requires a special tool called a chuck key to tighten and loosen its jaws. This tool usually looks like an L-shaped wrench with a handle on one end and teeth on the other that fits into the side of your drill’s chuck.

Understanding how to put a bit into a drill is an essential skill for any DIYer. With this easy-to-follow guide, you’ll be able to confidently remove and insert bits in your drill no matter what kind of chuck it has.

With this easy-to-follow guide you’ll be able to confidently remove and insert bits in your drill, so you can tackle your next DIY project like a pro. Let’s get started!

Content from Saws on Skates® may not be reproduced or used in any manner whatsoever without the express written permission of the author.

When it’s time to remove the bit, simply reverse these steps. Please use caution when removing drill bits as they become hot with use.

Have you ever read directions that said, “chuck the bit in your drill?” I know it may sound strange, but chucking a bit simply means inserting it in your drill.

A drill chuck often referred to simply as a chuck, is a clamp that holds a bit in place at the end of a drill. The chuck is powered by the drill’s motor and rotates as you turn the drill on and off.Related: How to Use a Drill (Tips & Techniques)

My cordless drill has a one-part keyless chuck. To use this style, you hold the drill’s body with one hand and use the other to turn the chuck clockwise to tighten and turn the chuck counterclockwise to loosen.

If there’s already a bit in your drill, you can take it out now. If the bit won’t come out, widen the chuck’s jaws until you can remove it.

Drill bits can sometimes get caught between two of the three jaws, which will cause the bit to spin off-center, making it impossible to drill holes or drive screws. If your bit is misaligned, open the chuck and reposition it, so it’s centered in all three jaws.

A chuck has adjustable jaws that, when you turn it in one direction, tighten around the bit, and when you turn it in the opposite direction, it loosens so you can remove or insert a new bit.

Thank you for stopping by. If you enjoyed this tutorial, would you please take a moment and pin it to Pinterest? I’d really appreciate it!

This article contains affiliate links. If you purchase from these links, I may earn a small commission at no additional cost to you. Visit my site policies for more information.

With its adjustable jaws, a drill’s chuck allows you to change between bits of different shapes and sizes, such as round or hexagonal shank. The shank is the smooth part of the bit inserted into the chuck.

Once your new bit is in place, you can plug in your drill or install the battery, and then you’re ready to drill or drive!

If you already have a bit installed in your drill, you can remove it now. If it refuses to come out, widen the chuck’s jaws until you can remove it.

Need help changing a drill bit? I’ll guide you through it step-by-step so you can change any bit, no matter what drill you have!

Milan Conception...engineering company specialized in the design and manufacturing of industrial machinery..leader in the automotive weather-strip industry.

You’ll need to open your chuck’s jaws if they’re closed, not opened wide enough to insert the bit, or if there’s a bit already in the chuck.

Indexable Carbide Insert Roughing End Mills. Serrated Edge to reduce tool pressure. Cut 0.010 to 0.020 undersize to allow for Finishing.

A drill bit is a tool used to remove material from a surface to make holes, and it is almost always circular in cross-section.

Driver bits such as Phillips and slotted are used to drive screws and other fasteners, while drill bits make holes in materials like wood, metal, and plastic. Commonly used drill bits include twist drill bits, spade bits, hole saws, Forstner bits, and countersink bits.

Unsure how to put a drill bit in your drill? I’ve got you covered no matter what kind you have! The same methods apply, whether it’s a DeWALT, Black and Decker, Milwaukee, Makita, Ryobi, Craftsman, or any other brand.

Download and use 100000+ Playing Flute stock photos for free. ✓ Thousands of new images every day ✓ Completely Free to Use ✓ High-quality videos and images ...

Feb 21, 2012 — Generally, use conventional milling on manual mills w/o backlash takeup in all cases, or on any mill, milling away a heat affected (rock hard) zone.

The Uni Back Hold Back Wrench helps you keep your worksite safe by preventing injuries, replacing a box end wrench when tightening fasteners.

The drawback to a keyed chuck is if you lose the key, you won’t be able to change the bit. Anyone that has ever owned a drill with a keyed chuck understands the panic when you’ve misplaced the key!

0086-813-8127573

0086-813-8127573