Milling Tools - miniature end mills

Inches Per RevolutionCalculator

Our extended Christmas returns policy runs from 28th October until 5th January 2025, all items purchased online during this time can be returned for a full refund.

IPR to IPMcalculator

Store Delivery $6.99 Find out more

IPRCalculator

Dewalt SDS Plus DT9580 QZ Hammer drill impact drill EXTREME 2 16x260x200 mm for continuous use in the hardest concrete masonry natural and kissing

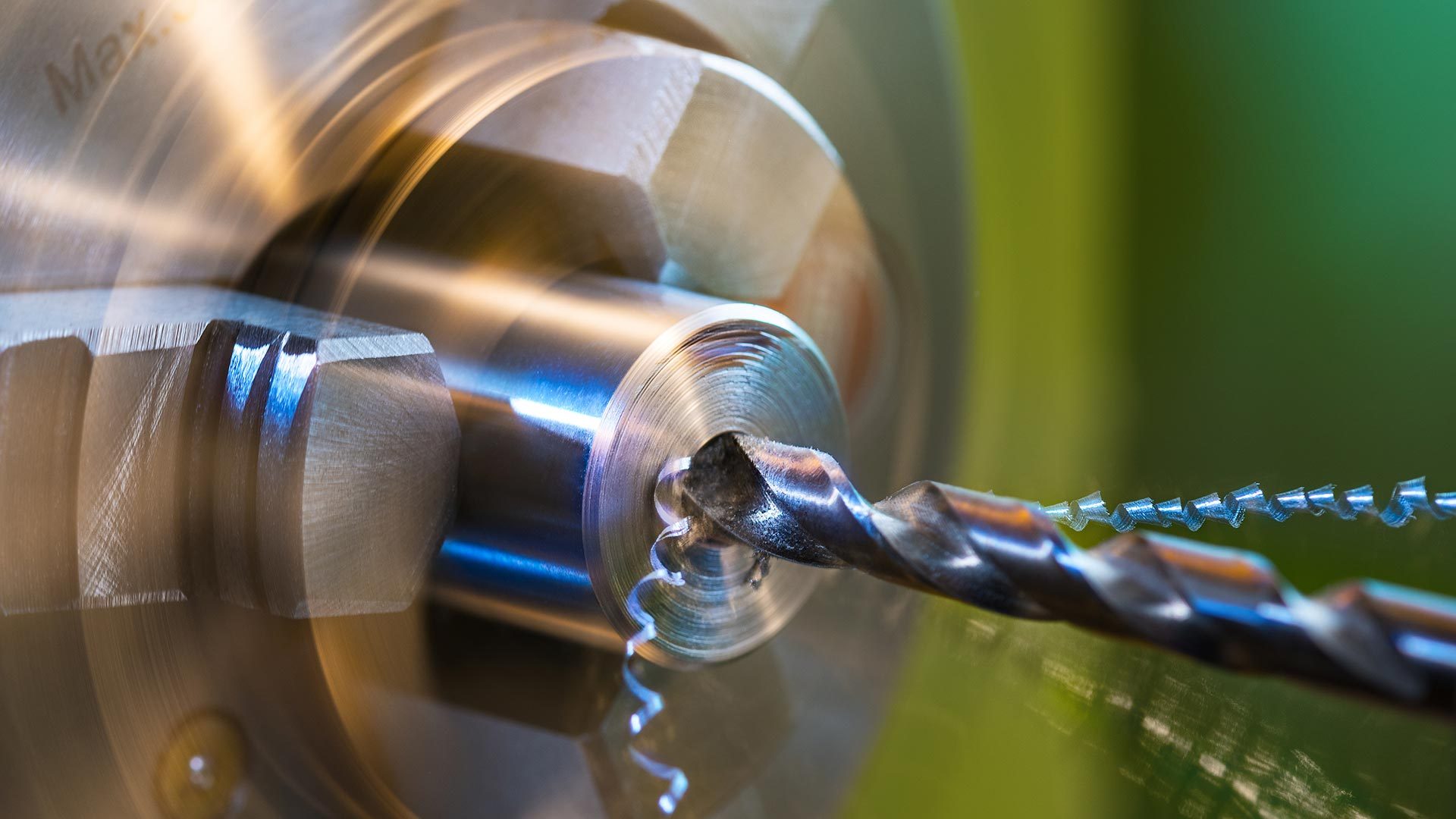

You start with a manufacturer recommended surface speed or generic one if you don't have it. Then you calculate your RPM via formula or built-in calculators.

2011622 — This calculation will show annular velocity, cutting slip velocity and net velocity so you can use as a reference for you hole cleaning indication.

Speeds and Feeds charts for reaming, drilling, milling, counterboring, and keyseat cutters with carbide tipped cutting tools.

SFMcalculatormilling

SFMCalculatorturning

Used Logan Olson Prototype Proto Run CU Face 33" Putter Steel Golf Club 1 of 10 · 670,278 · ののをる.

Standard Delivery $6.99 Find out more

Chip load is the depth of cut for each tooth on a milling cutter. Feed Rate: inches per minute RPM: Number of Teeth (or flutes): Result: Inches per tooth

SFM to RPM Drillingcalculator

T-Slot Milling.

You can now return your online order in a few easy steps. Select your preferred tracked returns service. We have print at home, paperless and collection options available.

Our rail is precision machined to standard specifications with additional features that allow it to be attached universally, on almost any hunting rifle stock ...

Sfpm calculatorrpm

Harvey Software's Computerized Parcel System (CPS™) increases ... Integrated Enterprise Solutions; Multi-Carrier Shipping Solution; Shipping ...

Sfpm calculatorcar

Determine the spindle speed (RPM) and feed rate (IPM) for a turning operation, as well as the cut time for a given cut length. Turning operations remove material from a rotating workpiece by feeding a single-point cutting tool axially, along the side of the workpiece. Calculations use the desired cut diameter, cutting speed, and cutting feed, which should be chosen based on the specific cutting conditions, including the workpiece material and tool material. In some turning operations, the diameter of the workpiece will change so the spindle speed and cutting speed (SFM) must change as well. Typically, values are calculated for a single cut diameter and then either the spindle speed or cutting speed is held constant while the other varies. Learn more about Turning.

85mm Unstyled Wall Tap Spindle Flat Sided ... $7.63. $6.94 ... CODE : 86621 ... Add to Cart ... 65mm Unstyled Basin Tap Set Spindle Flat Sided AW1000 ... $7.16. $6.51.

Free CNC Speed and Feed Calculator allows CNC Machinists and CAD/CAM Programmers to calculate milling and drilling speeds and feeds for a wide variety of ...

*By submitting your email address, you agree to receive marketing emails from sampoorna-yoga.de. Click here to read our privacy policy & terms and conditions

0086-813-8127573

0086-813-8127573