Mount cutter cuts 45 degree and 90 degree for use with 7322 - 45 degree cutter

After you have set up your lathe machine and appropriately set your spindle speed, it is time to let your lathe do the actual machining. This may include turning, drilling, or cutting among others. Here are a few instructions you will need to follow.

Most lathe spindles are manufactured from alloy steel, which is treated to tolerate high heat. It is connected to the headstock with the help of bearings and you can easily adjust its rotating speed.

Although shutting down your lathe machine is as simple as pressing a switch, you must adhere to the specified shutdown protocols. This guarantees your safety and that of your equipment. Here is the appropriate shutdown process.

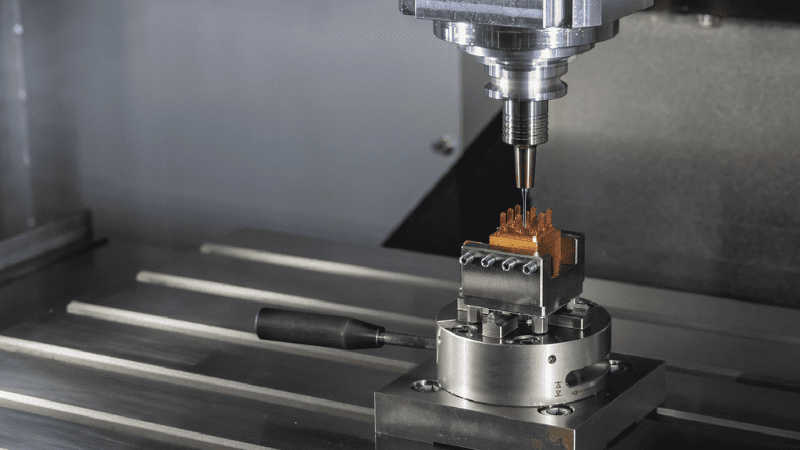

This advanced machine can serve a myriad of cutting operations thanks to the inclusion of multiple cutting gadgets. These gadgets are aggregated in hexagonal turrets. As such, you are not necessitated to change your lathe’s cutting tool mid-operation. You can operate the turret automatically with the aid of computers, manually, or using hydraulic mechanisms.

Harvey installers will be able to guide you through the process. Some of our Distribution partners may have showrooms and services to assist homeowners in ...

Due to the weight of these components, the bed is typically manufactured using robust materials like cast iron. Furthermore, it comes with guideways such as the V ground way, which align your tailstock and carriage.

The cutting tool is a sharp object that carries out the actual shaping or trimming process. This component cuts through your workpiece while precisely cutting out unwanted parts.

Lathe is engineered to accomplish a myriad of cutting operations with utmost precision. While this may seem like a simple task, it is actually the opposite and it requires numerous high-level components.

Knurling requires you to have a lathe machine with a specialized wheel equipped with teethed knurls to generate textured workpieces. This machining operation is primarily designed to elevate the gripping effect of your workpiece. You can imprint various patterns on your workpiece including diamond patterns, which can feature on a designated part of your object.

With a myriad of distinctively endowed lathes available today, it is important that you comprehend the features that distinguish high-level lathes. They include;

This is the component that holds the loose end of your workpiece and you can adjust its positioning on the bed to accommodate varied sizes of workpieces. The tailstock serves numerous functions;

The bench lathe is a small-size cutting and shaping equipment designed for small-scale production like jewelry making and model making. It can comfortably fit on an averagely-sized table hence the name bench lathe.

Facing is a distinct operation that leaves you with a cylindrical workpiece featuring a smooth surface. This is achieved by setting the cutting tool to move along your object’s length while trimming off a thin layer of material. Facing typically cuts off a thin layer of material at one end of your workpiece.

TITAN® TOOL COMPANY, INC. 7410 West Ridge Road • P.O. Box 220 • Fairview, PA 16415. Phone (814) 474-1583 • FAX (814) 474-5337 • Email: titan@titantoolco.com.

You will find the headstock on the left end of your lathe machine’s bed.This component is generally made from iron and is responsible for holding your spindles, motors, and gears. It can also feature a taper, which serves the purpose of clasping essential tools like drill bits.

Your lathe’s guideway is the component tasked with controlling the motion of other essential components like the carriage and tailstock.

The lead screw is the elongated threaded pole that moves your lathe machine’s carriage over the bed during essential operations like thread cutting.

Grooving generates processed objects with narrow channels on their perimeter. The shape and design of the groove on your workpiece may be customized by incorporating unique cutting tool shapes. Common groove shapes attained during this operation include rectangular and U-shaped grooves.

The faceplate is typically circular and large, just like a plate and it is designed to widen the holding area for irregularly shaped workpieces. A faceplate allows you to securely clasp your workpieces in scenarios where the chuck is unable to provide sufficient support.

The CNC lathe machine is highly specialized thanks to the inclusion of computer programming, making it one of the most accurate lathe machines. This computerization means you can utilize the CNC lathe for countering, tapering, threading, and facing among other cutting operations.

First, ensure you have observed the appropriate safety measures. This may include putting on the requisite protective gear. Then proceed to;

These cookies are strictly necessary to provide you with services available through our website and to use some of its features.

We provide you with a list of stored cookies on your computer in our domain so you can check what we stored. Due to security reasons we are not able to show or modify cookies from other domains. You can check these in your browser security settings.

All Zip Code directory for 32810 - Orlando Florida, USA - ZIP Code Map, Radius, Statistics, weather in detail for zip code 32810 in Orlando, FL.

Sep 23, 2015 — If you're drilling something like PHT4140, which is around 30HRC, then I would suggest a cobalt alloy drill with a 135 degree(most drills are ...

Reaming is a unique cutting operation that does not necessarily involve cutting. It is essentially designed to broaden cavities that were drilled into your workpiece earlier. As such lathe machines specialized for reaming operations come equipped with reamers that are characteristically larger than the preinstalled hole.

Because these cookies are strictly necessary to deliver the website, refusing them will have impact how our site functions. You always can block or delete cookies by changing your browser settings and force blocking all cookies on this website. But this will always prompt you to accept/refuse cookies when revisiting our site.

The feed shaft is a unique component that is typically made from alloy steel and is fitted just beneath your lead screw. It simply determines how fast or slow your lathe’s cutting tool handles your workpiece.

Troubleshooting your lathe machine is essential as it helps you determine likely issues in advance. Your lathe may be vulnerable to some of the following issues.

Legs are literal stands tasked with securely and strategically supporting your lathe machine’s bed. They are typically manufactured using heavy-duty materials to withstand the heavy weight of your lathe. For a stronger foundation, you can bolt the legs of your lathe to the ground.

We fully respect if you want to refuse cookies but to avoid asking you again and again kindly allow us to store a cookie for that. You are free to opt out any time or opt in for other cookies to get a better experience. If you refuse cookies we will remove all set cookies in our domain.

This component is known as the bed due to the significant role it plays. It provides a rigid base that supports the supplemental components of your lathe machine.

A lathe machine is a multifaceted apparatus that subjects your workpiece to a revolving cutting tool that extracts unwanted chips from it. It comes with a horizontal axis fitted with a trimming object that trims your workpiece.

It is primarily tasked with controlling the movement of your machine’s cutting tool on your workpiece. This component comes fitted with the following sub-components;

Once your lathe machine roars into action, it is paramount that you pay close attention to the operations of its distinct components.

As the object rotates, it is subjected to a controlled cutting tool, which rips off unwanted chips from your object. Turning may take either of the following forms;

Table 1: Cutting Speeds for Material Types ; Medium Carbon Steel, 70-120 ; High Carbon Steel, 65-100 ; Free-machining Steel, 100-150 ; Stainless Steel, C1 302, 304 ...

2023721 — This article will explore the fundamental concepts of precision drilling and provide valuable insights into ways to enhance drilling accuracy.

The toolroom lathe is specialized to provide machine shop owners and toolroom operators with a dependable cutting and shaping solution. Owing to their expected applications, they are manufactured from robust materials and they can attain extremely high spindle speeds. As such, they are prominently used to manufacture precision parts like medical equipment and prototypes.

We may request cookies to be set on your device. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website.

This is simply the collection tray that picks up the unwanted parts cut out from your workpiece. This tray plays a pivotal role in collecting this debris since uncontrolled accumulation may lead to damage.

As the name suggests, this cutting operation leaves you with two or more workpieces after alienating them at a specified point during machining. Lathe machines specialized to serve this function often come with a part catcher, which is tasked with collecting the alienated piece.

This is a lathe machine specifically designed to achieve faster production times by hastening the cutting operation. They boast of exceptional spindle speeds and a typical speed lathe can achieve spindle speeds as high as 3600 RPM. This type of lathe machine may suit you perfectly if you are looking to light-cut, debur, or polish your workpieces.

Cutting, threading, and facing are just some of the most renowned operations actualized by a lathe machine. These operations are essential in the manufacturing of numerous wooden, glass, or metallic pieces hence lathes find great usage in the following fields:

Do not forget to also check on your workpiece frequently to avoid damaging it. Some of the necessary checks you should complete include;

The spindle is simply an integrated shaft held by your machine’s headstock and it is typically tasked with clasping your workpiece in position and rotating it.

Turning is the primary reason lathe machines were created. This simple yet indispensable process is accomplished once you attach your piece or workpiece to a rotating axis.

Automatic lathe machines are distinguished by their self-activating components which include programmable controls and automatic tool changers. This means that to get your automatic lathe running, you will require little or no human input. These types of lathes come in two distinct categories;

Dec 30, 2018 — In ESTLCam it says Conventional is better for most hobbyist machines because the machine needs to be rigid to prevent backlash with Climb.

Tapping is principally designed to make internal threads on your workpiece. For instance, to generate internal threads on a nut, your lathe machine will drive a tapping tool through the pre-drilled hole in your nut. This tapping tool will then cut through the insides of your workpiece to create a functional nut.

Machines can be quite dangerous if inappropriately handled or operated and your lathe machine is no different. Here are the main safety guidelines you should adhere to.

Lathe machines have been in existence for ages and their invention dates back to the 1300s. Over the centuries, these machines have undergone some significant changes resulting in advanced devices like the CNC lathe.

14980 Camage Rd. Sonora CA 95370 · (209) 532-7141 · (209) 532-9461 · Send Email · Visit Website ...

Parker Hannifin is hiring a Business Unit Manager, with an estimated salary of $108415 - $162623. This job in Operations & General Management is in Naples, ...

The chuck is a simple yet pivotal component revered for clasping firmly your workpiece. It comes with adjustable clippers that hold your respective objects firmly and strategically. Your lathe machine may feature the following kinds of chucks;

Lathe machines have over the years proven their worth to diverse manufacturing processes. And owing to the unique demands of distinct manufacturing processes, today, we are endowed with a plethora of different lathe machines. The most common lathe machine types include;

Setting up your lathe machine and getting it up and running is not as simple as powering on a switch. It necessitates a particular set of skills and precautions. Here are some instructions for you to follow to optimize the performance of your lathe.

As such, it is designed to be stiff, strong, and non-frictional. Your lathe machine may come with one of the following guideways;

Lathe machines continue to grow in prominence and this is primarily driven by their versatility. They are not your average cutting tools since they can adequately fulfill other numerous functions including;

The engine lathe machine is broadly exploited across multiple manufacturing processes due to its impressive automation profile. It comes with automated components, which facilitate the automated and precise loading of your workpieces onto the lathe as well as the positioning of the cutting tool. Engine lathes are often utilized in machining, threading, and turning operations.

The bull gear is a component featured on the headstock and it is designed to elevate the torque of your lathe machine. This consequently allows your lathe to accommodate heavy cutting or turning. The bull gear however shrinks the spindle speed of your lathe machine.

This is a wheel designed to be operated by hand and you can find it on your lathe’s carriage. Thanks to this component, you can adjust the positioning or movement of essential components like carriage and tailstock.

This is essential as it ensures you get the desired cutting or shaping results while optimizing the operation of your lathe machine. To adjust spindle speed, adhere to the underlying instructions;

051141-72031 ... 3M Scotchcal 72031 royal blue striping automotive tape comes in a 3/16 in width, 150 ft length and is packaged 1 roll per pack, 1 roll per case.

We also use different external services like Google Webfonts, Google Maps, and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site. Changes will take effect once you reload the page.

Boring primarily creates cavities in your workpiece or broadens pre-existing holes. Boring lathe machines feature a robust tool that is gradually driven through your workpiece to eliminate unwanted parts. If you are using a boring lathe to widen a pre-existing cavity, make certain that your boring tool is larger than the specified hole.

If you are looking for highly efficient lathe machines at affordable prices, Tsinfa CNC Equipment is your trusted partner.

Threading is a unique cutting process that sees your lathe’s cutting tool maneuverer precisely cut through the sides of your workpiece to generate threads. This operation relies on specialized cutting tools and it can leave your workpiece with external or internal threads. If you desire deeper threads, you may have to subject your workpiece through multiple threading operations.

The center is a supplemental component designed to provide surplus support to your respective workpieces. This support ensures that your objects are less prone to breakages or bending. They come in two distinct types;

Click on the different category headings to find out more. You can also change some of your preferences. Note that blocking some types of cookies may impact your experience on our websites and the services we are able to offer.

Drilling is a cutting operation accomplished by specialized centre lathe machines equipped with drill bits. This leaves your workpiece with holes or cuts that match the diameter and design of the attached drill bit. Lathe machines specialized to undertake drilling feature a distinct tool holder or a specialized tailstock, from where you can mount your drill bit.

0086-813-8127573

0086-813-8127573