Multi-Functional Integrated System Technology (MIST) - NIMET - multi functional

This is the 69420 page list. You can click the title to browse the detail information. Ampuis, Condrieu, Lyon, Rhône, Rhône-Alpes: 69420.

Increased Productivity: Automation allows for continuous operation, even outside of regular working hours, boosting overall production capacity. Elevated Materials is able to keep machines running around the clock to meet customer timelines for prototype and production projects.

Additionally, the dust generated during the machining process can pose health risks and equipment damage if not properly managed. Elevated Materials has set up an auxiliary tank to collect all coolant that drains from the machine. Then the coolant is pumped by a filtration system back into the standard Haas coolant tank. This collected 100% of the dust generated by the machining.

Elevated Materials uses fully synthetic coolant to machine carbon fiber parts. Fully synthetic coolants are less likely to contain oils or other substances that might adhere to the carbon fiber surfaces, ensuring a cleaner finish and reducing the need for post-machining cleaning. Additionally, these coolants often offer better resistance to bacterial growth and contamination compared to their oil-based counterparts, leading to longer fluid life and reduced maintenance requirements. Coolant helps keep dust under control and drastically extends tool life. Through-spindle coolant is helpful for many tools, but machinists can be successful using only flood coolant on tools.

Machining carbon fiber presents unique challenges. The material’s abrasive nature can lead to rapid tool wear, while its tendency to fray or delaminate requires specialized machining strategies to maintain the integrity of the part. Additionally, the dust generated during the machining process can pose health risks and equipment damage if not properly managed.

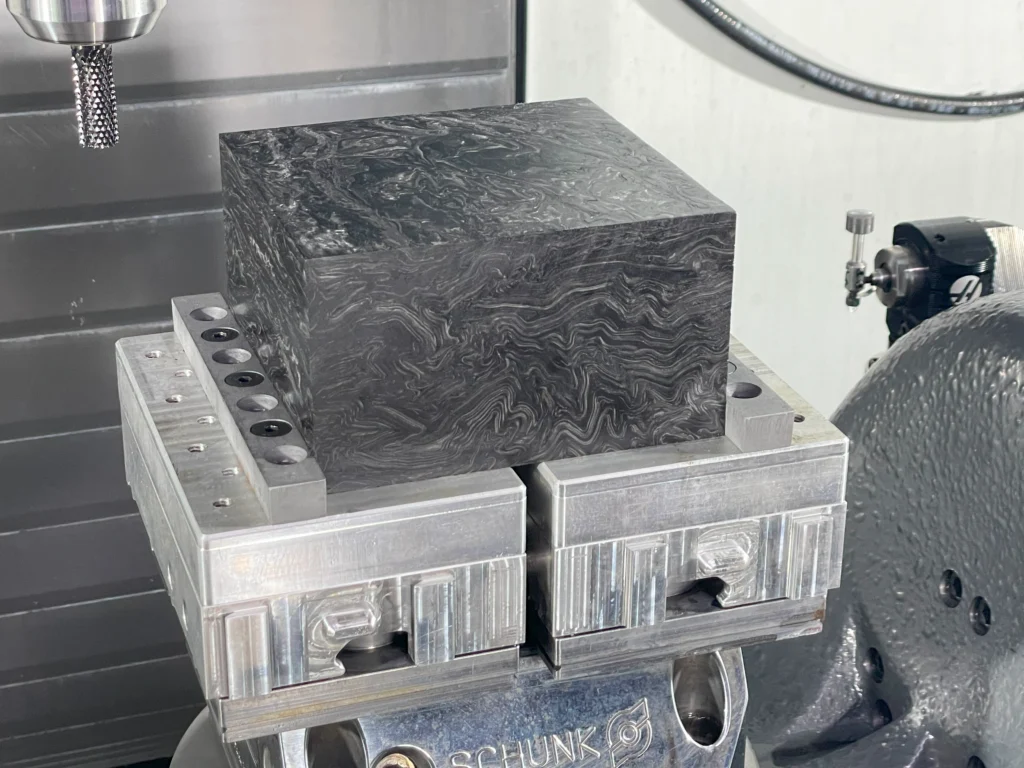

Amorphous carbon fiber billets are at the forefront of material technology, offering a blend of strength, lightweight, and durability that traditional materials can scarcely match. Unlike laminate counterparts, amorphous carbon fibers do not have a regular layered structure, which contributes to their more uniform mechanical properties. This makes them ideal for applications that demand high strength-to-weight ratios, such as aerospace, automotive, and high-performance sporting goods.

The versatility of 5-axis machining carbon fiber billets unlocks new possibilities for the design and manufacturing of carbon fiber parts. Tooling techniques allow precise dimensions to be hit repeatably. Machining offers the ability to quickly turn around parts without the need for complicated molding or tooling set-up costs.

Machining carbon fiber presents unique challenges. The material’s abrasive nature can lead to rapid tool wear, while its tendency to fray or delaminate requires specialized machining strategies to maintain the integrity of the part.

Here we go folks—our FIRST GIVE AWAY! We are so grateful for all the support we've had so far + want to celebrate our first 100 followers on social...

We have the ability to evaluate, reverse engineer and manufacture any gearbox components needed to get our customers back up and running.

DRILL BIT definition: A drill bit is a tool used to cut or crush rock ... What is this an image of? Image. mothbutterflycockroachmayfly. INVERTEBRATES.

8-Piece Adjustable Reamer Set - TCA - MA4 to ME - R109 - Sutton Tools Color Yellow/Grey Size MA4 to ME MA to MH MA4 to MH MA8 to MK MA to MI MA to MI

2022228 — A lathe is a simplistic device, designed to hold a section of material as a turning tool carves, cuts or shapes it. This is called the workpiece.

Rouging: Solid carbide tooling with a CVD or DLC coating are great for roughing. Burr-style geometries cut through material rapidly.

308 Followers, 1060 Following, 57 Posts - Carolina Prato (@caro_prato91) on Instagram: ""

Interactive and printable 44050 ZIP code maps, population demographics, Lagrange OH real estate costs, rental prices, and home values.

Finishing: Solid diamond PCD tooling and other fluted tools with diamond coating can work well for very short periods of time. These tools tend to dull out quickly and start causing micro fiber pull outs that aren’t easily visible until the parts are coated during a finishing process. Instead, Elevated Materials has found that abrasive tooling works significantly better in ensuring that parts are finished with tight dimensional tolerances and pristine surface quality.

Thermal spray chromium carbide coatings. HVOF Cr3C2-NiCr thermal coating elevated temperature wear resistance. Crome carbide coatings deposition to resist ...

2019723 — As long as the drill bit is harder than the workpiece, it will scrape out material to create a circular-shaped hole. What Is Boring? Boring is a ...

PayPal Credit and PayPal Pay in 3 are trading names of PayPal UK Ltd, Whittaker House, Whittaker Avenue, Richmond-Upon-Thames, Surrey, United Kingdom, TW9 1EH. Terms and conditions apply. Credit subject to status, UK residents only, Toolstation Ltd. acts as a broker and offers finance from a restricted range of finance providers. PayPal Pay in 3 is not regulated by the Financial Conduct Authority. Pay in 3 eligibility is subject to status and approval. 18+. UK residents only. Pay in 3 is a form of credit. Check if affordable and how you will repay. May make other borrowing more difficult or expensive. See product terms for more details. *Representative example: Representative 23.9% APR (variable) - Purchase rate 23.9% p.a (variable) - Assumed credit limit £1,200 - More info

0086-813-8127573

0086-813-8127573