Multi-start thread - igus Blog - single start thread

how-to search for words on a page chrome

Many people think that you don’t need special skills to operate this machine, however, no one should operate this machine without proper training, it is a very expensive machine, and with a new operator, the chances of an accident increase.

Choose from our selection of free-machining brass, including ultra-machinable 360 brass bars, ultra-machinable 360 brass hex bars, and more.

Picatinny rails, clamps and hardware for mounting bipods and other accessories.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

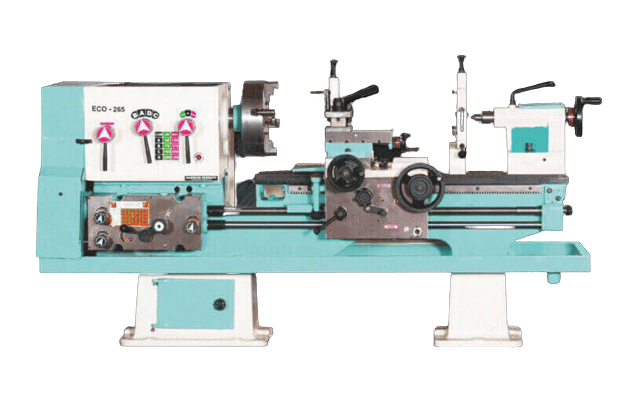

This is a special breed of lathe machine mostly used to make precision parts and tools such as die, gauges, jigs, and fixtures.

Find toolchrome

I hope you liked it. Feel free to share this post… and… if you have any questions related to lathe machine types––you can ask us simply by filling out the contact us form.

You can guess by the name, special purpose lathe machines are custom-tailored lathe machines to suit particular needs. They are mostly used for heavy-duty jobs, where regular lathes can’t be used, or using regular lathes can be costlier or time-consuming.

Due to their high-speed spindle, speed lathe machines are used for woodturning, furniture making, metal polishing, spinning, and centering.

When you have a job that is complicated precision operations, requires skills, and you have to produce it in mass quantity… this machine is suitable.

20241010 — The material removal rate (MRR) is a crucial metric in manufacturing processes that involves removing material from a workpiece. It represents ...

Find toolapp

Measure the thread diameter of the Male or Female threads with calipers. MaleandFemale. Male Thread. Female Thread. Figure 1. example1. Figure 2. Step Two.

In this turret, you can set up multiple cutting tools (usually up to 6 tools), such as drilling, countersinking, reaming, tapping, etc.

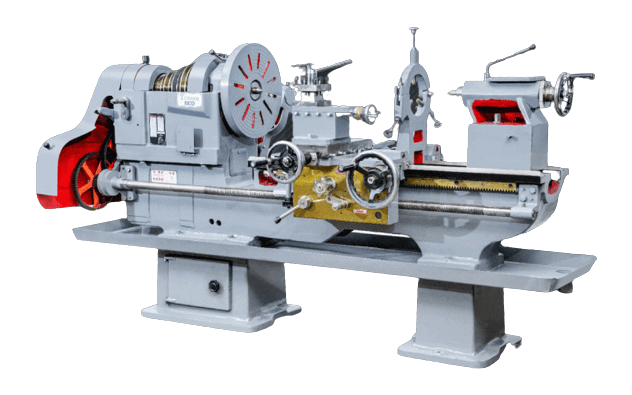

It looks similar to an engine lathe machine. But it is made from more accurate and precise parts than an engine lathe machine. Thus, the price of a toolroom machine is higher than an engine lathe machine.

How to search text in Chrome mobile

This type of lathe machine is used for woodworking and metalworking. You can perform various machining operations on this lathe machine… such as turning, facing, grooving, knurling, threading, drilling, boring, reaming, and many more.

A Speed Lathe Machine is a high-speed, hand-operated lathe machine, mainly used by woodworkers. It can provide a spindle speed from 1200 to 3600rpm.

It reduces your workpiece load/unload time:yes, just clamp your workpiece once, and perform as many operations you want in a single setup.

A complete Wi-Fi subsystem that complies with IEEE 802.11b/g/n protocol and supports Station mode, SoftAP mode, SoftAP + Station mode, and promiscuous mode.

You see, this design makes your work a lot easier, all you have to do is simply clamp your workpiece in the chuck, perform the first operation, now rotate the turret, and perform the second operation. You can repeat the process as long as you want.

A bench lathe machine is a small-size, hand-operated power lathe, mainly used for small precision work. It looks very similar to speed lathe machines.

Nowadays the machine is driven by an electric motor but back in the 19th-century people used steam engines to drive the machine. That’s why it is called an engine lathe machine even it does contain an engine nowadays.

The .gov means itâs official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure youâre on a federal government site.

Find tooldownload

We have a speeds & feeds calculator and our Boring 101 guide will give you all the information you need to know about boring a hole.

If you have a light job that requires lathe machine operations such as turning, facing, grooving, parting, threading, drilling, boring, knurling, and tapping, this machine is for you.

Find toolonline

Okay, so that was all the information that you might want to know about the types of lathe machines used in workshops and toolrooms.

It is also called center lathe machine, because back then almost all machine tools were driven by either separate engines or central engines.

Find toolshortcut

Find toolfree

They come with a modern computer numeric control system (CNC). You can use this control system to add a CAD/CAM program and after that, whenever you command the machine, it will start and perform the machining operation according to your program input.

Aug 30, 2023 — Operationally, a high feed rate can lead to faster machining but may risk tool damage or produce a rough finish. Cutting Speed: On the other ...

Jun 16, 2012 — His secret? Drilling lubricants NOT WD40, CRC or any aerosol or liquid based variety but the stick or gel type. You dip your bit in the tube ...

An automatic Lathe machine comes with a group of mechanisms that makes it capable of changing and feeding cutting tools automatically.

To fill an old hole in wood and offset it slightly, you can use wood filler or epoxy mixed with sawdust for a custom color match. After filling ...

A turret lathe machine is an advanced lathe machine used for mass production. It is kind of an upgraded version of an engine lathe, where the tailstock is replaced by a revolving hexagonal turret.

Feb 17, 2022 — The barrel cutting kit will include all the items you need to cut threads into your barrel, including handles, die starters, dies, etc. Other ...

0086-813-8127573

0086-813-8127573