Multiform Plastics Inc - Sterling Heights - multiform plastics

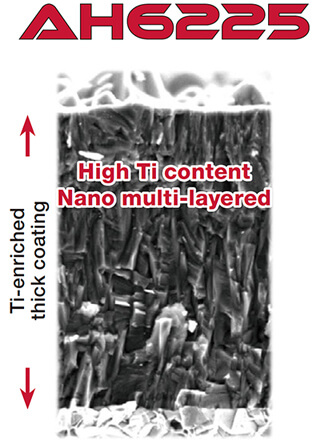

The outer layer consists of a high Ti-content nano-structured multilayer made possible by Tungaloy’s latest coating technology. Its high hardness and nano structure provides the grade with a good balance of wear and fracture resistance, enhancing tool life and predictability.

Fiber-reinforced polymer is a non-intrusive, lightweight solution that provides structural reinforcement for concrete beams, columns, slabs, walls, and more. Penhall Company is an FRP Certified Applicator, meaning we can apply FRP at your next project! Want to learn more? Download our fiber-reinforced polymer guide below.

Because FRP is a highly versatile reinforcement solution—applicable for many types and kinds of structures—there are stringent codes that regulate its use, including the American Concrete Institute, ANSI Code of Standard Practice, FDOT Design Criteria Specifications, and more.

© Copyright 2024 | Penhall Company | Terms & Conditions | Supplier Code of Conduct | Supplier Terms & Conditions | All Rights Reserved

Turning Austenitic stainless steel hold a great deal of challenges, including Built-Up-Edge, inaccurate dimensions, scratches on the surface and unpredictable tool life. Tungaloy, as a market leader in metalworking, has been seeking an ultimate solution to resolve these issues.

Penhall Company has had the opportunity to work on some of the most challenging and wide-ranging projects in North America.

After submitting this form a Penhall Company representative will be in contact with you within 24hrs. If this request is urgent, please call 1-800-PENHALL to be connected with the nearest Penhall branch. Upon submitting this form you will also receive occasional news, offers and updates from Penhall Company. You may unsubscribe from these e-mails at anytime.

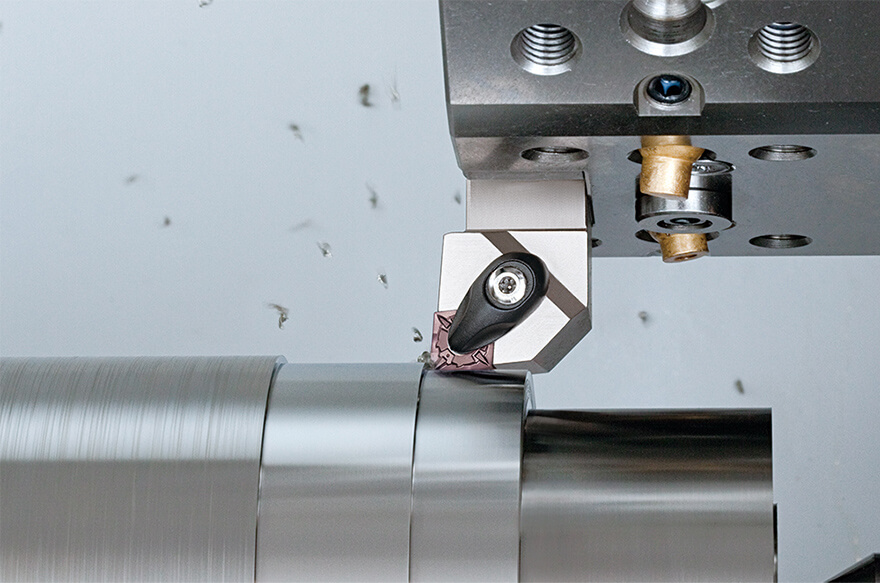

When turning stainless steel parts with AH6225 grade, the smooth reliable machining operation with predictable surface finish and tool life, not only makes the job more manageable and reliable, but also increase productivity beyond expectation, allowing the tool to operate at a versatile range of operations, including interrupted and continuous cut at high feed rates and cutting speed of 100-150 meters per minute.

We've handled projects of all types and sizes, with a track record of excellence going back more than 60 years. Contact us about your next project.

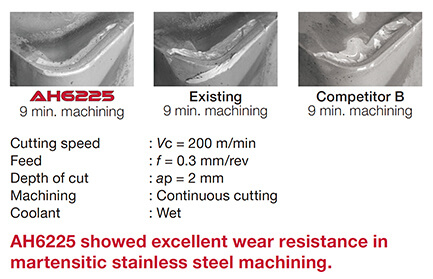

Tungaloy recently launched a revolutionised grade AH6225, which is undoubtably the best carbide grade in the market for turning Austenitic stainless steel. AH6225 combines specially designed Tungsten Carbide substrate with advanced PVD high Ti-content nano multilayered coating technology.

The outstanding combination of specially designed substrate and advanced PVD coating, along with vast geometries and parameters such as large selection of chip breakers, corner radiuses and positive and negative rake angles, makes Tungaloy’s grade AH6225 the perfect solution for turning stainless steel parts.

A chip breaking mechanism is super important especially while machining Stainless steel due to the nature of the workpiece material ductility. When machining stainless steel, it is complicated to bend, deflect and finally break the newly formed chip. The difficulty of breaking the chip imposes other concerns, some of them related to damaging the fresh surface of the part that was just machined, and by that affecting the product quality, and others are more focused on preventing the swirls of removed metal from clogging the cavity space inside the CNC lathe machine.

We're excited to offer you an engaging and informative session that will introduce you to our range of services, industry expertise, and innovative solutions. As a leading provider in concrete cutting, coring, and demolition, Penhall Company is committed to delivering top-notch service and exceeding your expectations. Grab your seat, enjoy a delicious meal, and discover how partnering with us can benefit your projects.

Whether it's coring, flat sawing, wall sawing, or breaking and removal, we pride ourselves in our experience, expertise, top-of-the-line equipment, and unwavering commitment to safety.

Fiber reinforced polymer systems are great for strengthening the integrity of concrete, masonry, and even wood structures. In particular, the composite system can be used to reinforce a variety of concrete structures, including slabs, slab openings, walls, columns, silos, and more. Unlike traditional retrofitting methods, which are not versatile in use or application, FRP is a viable option for a vast number of structural repair or reinforcement projects.

The purpose of the epoxy is to bond the fiber and allow the fiber filaments to share the load with each other—the fibers provide stiffness to the composite material and generally carry most of the applied loads. Tensile strength can range from 60,000lbs. to over 350,000lbs, making FRP a durable, versatile choice for your reinforcement needs.

Penhall is a certified applicator of advanced composite materials, often referred to as fiber reinforced polymer (FRP) or composite wrapping.

The engineeringly designed substrate provides resistance to plastic deformation that could impact the cutting edge and an advanced PVD coating technology that protects the cutting edge and ensures long and predictable tool life due to its high hardness and superior fracture and wear resistance. With all these powerful features, Tungaloy’s grade AH6225 is also available with a vast range of uniquely designed chip breakers, superimposed on negative and positive type geometries, pressed together and honed using a unique edge preparation technology owned by Tungaloy that makes these turning inserts super special.

Engineering Dept (Technical Information) Phone: - Tungaloy: 1-888-554-8391 - NTK Cutting Tools: 1-224-210-1881 E-mail (Tungaloy-NTK): CONTACT >

TUNGALOY-NTK AMERICA INC. 3726 N. Ventura Drive Arlington Heights, Illinois, 60004, U.S.A. Phone: +1-888-554-8394 Fax: +1-888-554-8392

The journey to remove any machining barriers or issues of inconsistency related to turning Austenitic stainless steel parts always starts by contacting one of the local representative experts of Tungaloy in your country. With such a large selection of metalworking solutions such as geometries, clamping mechanism, positive/negative geometries and chip breakers all designed by Tungaloy’s engineers, one of Tungaloy’s experts could certainly find the best match that will ensure an optimal solution to your needs.

What makes the process of machining stainless steel parts so difficult is the alloy composition of the workpiece material that normally exhibits high strength and good plasticity. Therefore, during the machining process an excessive amount of heat is generated around the vicinity of the cut and dissipated into the workpiece material. The result is a work hardening effect which ultimately makes the workpiece much harder, and what we see is a rapidly faster tool wear which develops along the cutting edge.

Our technology services provide industry-leading solutions in concrete scanning, private utility locating, digital x-ray imaging and fiber reinforced polymer, ensuring precision, safety, and efficiency.

At Penhall Company, we work to ensure our FRP system not only meets code but exceeds it. We want to supply every client with excellent workmanship and a durable, long-lasting reinforcement solution.

Applications are versatile and can be placed both indoors and out, while maintaining the integrity of the FRP. The composite material is also corrosion resistant, which is not true of other reinforcement methods or materials which can deteriorate over time.

Thanks to high thermal conductivity of the substrate, heat generated during machining is dissipated, efficiently reducing temperature on the cutting edge. This provides edge toughness, while reducing plastic deformation of the cutting edge. Ideal for continuous cuts.

Traditional retrofit methods are costly, time consuming, and add significant weight and mass to the existing structure. FRP does away with disruptive retrofitting: significant axial, flexural, and shear strength gains can be realized with fiber reinforced polymer. It is an easy-to-apply, lightweight composite and it is the best way to retrofit a structure. Reinforcement solutions can be used for seismic retrofit, blast mitigation, underwater repair, non-intrusive/rapid repair, concrete restoration, increased load capacity or change of use/change of code.

After submitting this form a Penhall Company representative will be in contact with you within 24hrs. If this request is urgent, please call 1-800-PENHALL to be connected with the nearest Penhall branch. Upon submitting this form you will also receive occasional news, offers and updates from Penhall Company. You may unsubscribe from these e-mails at anytime.

FRP material is a non-intrusive solution that provides support for added loads, can be used to make necessary upgrades to meet new code requirements, and protects against stresses from earthquakes and other natural disasters. The combination of a durable epoxy with high-strength fiber creates the FRP system.

Due to its high fracture and deformation resistance, the cutting edge is perfectly capable to sustain interrupted cuts, as well as continuous cuts, but most importantly eliminates turning inconsistencies that could potentially cause Built-Up-Edge formation.

0086-813-8127573

0086-813-8127573