Nails - what is a metal nail made of

Containing everything you need inside one handy and cost-effective kit — a wide range of durable bits means you’re ready to tackle your wood, plastic, metal, and masonry projects.

Some manufacturers recommend only using this type of drill bit in rotary mode when drilling masonry — to preserve the integrity of the modified tip. Therefore, dedicated masonry drill bits are still recommended for regular and/or repetitive masonry drilling — especially into concrete.

Countersink bits are used to create a bevelled opening at the top of a pilot hole. They’re generally found in 13 mm, 16 mm, and 19 mm sizes. There are also different styles for metal and wood.

Built from solid cobalt alloyed high-speed steel, they’re highly resistant to extreme temperatures and abrasion. Typically, these cobalt bits are utilised for drilling materials like stainless steel and other high-tensile steels, including cast iron, cast steel, bronze, and weld seams.

Be careful applying lateral force to the bit, as all drill bits are designed to be strongest when forward pressure is applied. Drill saws can be difficult to steer, and can therefore produce a somewhat inaccurate hole.

Tool Cobber has been designed to offer you – the consumer – a chance to do your research before you buy. There are a limited number of online resources available for detailed information on tools, especially in Australia. Most people go down to their local... more

When pressure is placed on the bit, the spring-loaded drill bit is pushed out of the metal sleeve and into the work, leaving you with a perfectly centred bore. Just like drill/countersink drill bits, the internal HSS drill bit can be replaced via a small grub screw. Self-centering bits are also identified by the size of the screw they’re meant to pre-drill.

ToolCobber.com.au is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. Additionally, ToolCobber.com.au participates in various other affiliate programs, and we sometimes get a commission through purchases made through our links.

These high-performance bits boast specially designed tungsten carbide tips with a diamond-ground edge. This combination allows them to function effectively in both hammer and rotary drilling modes. They can drill nearly every type of material — including wood, masonry, ceramic tiles, plastic, and metal.

Skilled craftsmen and cabinet makers can use this method to countersink screws or bolts, ensuring they’re level with the wooden surface, resulting in a clean and seamless appearance. This technique is compatible with various rotational machines, but I recommend using a pedestal drill for optimal precision.

They’re ideal for making holes in soft, thin materials, enlarging holes that have already been made, or light deburring. They generally have a titanium-nitride coating to reduce heat build-up and keep them fairly well-lubricated. There is also a very similar drill bit without the steps that is appropriately named a ‘conical bit.’

With split point bits to self-centre and improve accuracy, these steam-tempered HSS bits power through tough ferrous metals.

Generally speaking, two formats of Forstner drill bits exist. Continuously rimmed (as pictured) — create exceptionally smooth edges and are most suited to small bores. Rims with a saw-like tooth — although delivering slightly rougher cuts, are ideal for more substantial holes (typically exceeding a diameter of 2.5 cm) and boast increased durability.

Boasting durable carbide tips, this multipurpose combination drill bit set from Milwaukee can address wood, plastic, metal, roof tiles, PVC, and ceramics.

Purchasing a bit set — compared to buying individual bits — typically saves you significant money. Furthermore, it ensures you have a range of sizes and bit types for tackling different projects.

However, they require a drill with a specialised chuck. Although adaptors are available for standard drills, you then have the added problem and instability of the rounded shaft of the adaptor.

Deep hole drilling is a specialized machining operation used to create holes with large length-to-diameter ratios. It requires specialized cutting tools known as deep hole drilling inserts. This article aims to provide an overview of common deep hole drilling inserts and their applicable ranges, highlighting their features, advantages, and suitable applications.

Indeed you can! Tool maestros DeWalt sells a number of premium drill bit kits for the discerning DIYer and serious tradie — such as the multipurpose DWA1181 21-piece kit.

Forstner bits are specialised drill bit types commonly used for installing concealed hinges, usually 26 mm or 35 mm in diameter. They can bore large holes in wood, and their flat-bottom design enables users to pull just short of going through the piece of timber.

Solid carbide inserts are made from a single piece of carbide material. They offer excellent hardness and wear resistance, making them suitable for various deep hole drilling applications. Key features and applicable ranges include:

More correctly known as a twist or fluted bit, this accessory can be used on various materials, including wood, plastic, and metal. They feature a pointed tip and spiral flutes that run along the body, which assist in removing debris from the hole as the bit bores.

When selecting your ideal combo set, initially consider the materials you’ll be addressing in your most common jobs — and ensure the bits match your brief.

Self-centering drill bits are designed to drill accurate pilot holes for hinges and other hardware. The end of this drill bit type sits comfortably in the hardware’s countersunk holes and automatically aligns itself to the centre of the hole.

When purchasing a set of drill bits, it’s crucial to understand the types of bits that the kit includes — to ensure they’re suitable for your DIY or trade jobs.

They commonly include a 0.25-inch (6.35 mm) hexagonal shank, and arrive in a multitude of diameters — most commonly from six to 38 mm. What’s more, you can often extend their reach by utilising an extension shank, making them perfect for seriously deep drilling.

Unable to find the correct bits for your drilling jobs? Drill bit kits are your saviour! These handy, convenient, and cost-effective sets offer a variety of sizes and formats specifically designed to tackle all sorts of materials. From hanging shelves to crafting intricate cabinets — the perfect drill bit sets can handle any DIY project or trade job. Whether you’re a seasoned tradie, novice borer, or serious home improver — my guide will give you the knowledge to choose the perfect drill bit combo kit!

While round shanks deliver simplicity, hex shanks provide impressive grip and stability. Six-sided, they fit tightly into a hex chuck — providing an immense lock that remains firm under heavy torque and hammering,

Drill bit sets are collections of variously sized drill bits, sometimes including different types designed to drill into specific mediums. They offer convenience and affordability and ensure you always have the right bit for your trade or DIY jobs.

The singular cutting edge, with its discernable spur, scores the rim of the hole to create a pleasingly clean edge — while the large flutes on the drill bit rapidly remove wood chips. They commonly have a hexagonal shank to create a firmer and more secure connection between the chuck and the bit.

SDS was originally invented by Bosch in 1975 and stood for Steck, Dreh, Sitzt — roughly translating to stick, turn, seated. Today — since not that many people speak German — SDS stands for Slotted Drive Shaft or Slotted Drive System.

Excellent straightness and precision: Gun drills provide exceptional hole straightness and surface finish, ensuring high-quality results.

Are you fed up with never having the correct drill bits for your jobs, or frustrated that they shear or break mid-project? Then prevent your headaches with one of the most reputable and robust drill bit kits!

Yes! These metal-focused kits contain various-sized HSS (high-speed steel) or cobalt bits — designed for powering into different types of metals. Some high-end kits may also include speciality bits for boring stainless steel or thin sheet metal.

Each type of indexable insert has specific advantages and applicable ranges, depending on the material being drilled and the desired cutting conditions.

These bits have a normal HSS drill bit tip, but after the first 15 mm or so, the shaft of the bit changes into a unique abrasive pattern. When a lateral force is applied to the bit, this pattern is capable of sawing holes into wood or metal.

Although you can use Forstner bits in a standard hand-held drill, they demand significant downward force. Therefore, I suggest you employ a more grunty drill press.

Although suitable for metals, plastics, ceramics, tiles, and glass — it’s mostly pointless on wood, where it will split the timber.

These drill bits allow you to drill a larger hole than your drill’s chuck would normally allow. For instance, if you have a 13 mm (½-inch) chuck, you can get a reduced shank drill bit with a 16 mm diameter and a 13 mm shank. These bits can drill through wood, metal and plastics.

Whether you’re tackling wood, PVC, metal, or drywall, these kits save you from hunting in the dark recesses of your toolbox for the correct accessory — saving you valuable downtime.

These tungsten-carbide-tipped drill bits are designed for drilling smooth holes in glass and ceramic surfaces, including porcelain (with the exception of toughened glass). They have a precision diamond-ground carbide tip for exact pilot drilling that shaves rather than cuts. They must be run at a very slow speed, with no hammer action, and with the use of coolant (such as water, turpentine or kerosene).

A variety of SDS bits exist, dependent upon the brawn delivery of the drill — the most popular being SDS Max and SDS Plus. These specialised bits are built for heavy-duty masonry boring and offer longer lifespans than typical concrete and brickwork bits.

Masonry bits heat up rapidly during use, which can melt the tungsten brazing on the drill bit’s tip, allowing the tip to move and chip when drilling. To keep the bit’s temperature down, you should withdraw the bit regularly to clean its flutes and use the correct drilling RPM.

This specialised drill bit type, including porcelain, is generally used for hard-surfaced masonry. Drilling must commence at a 45-degree angle to the cutting surface to prevent the bit from slipping, and then the bit must be slowly straightened as drilling progresses.

CBN (Cubic Boron Nitride) Inserts: CBN inserts are designed for drilling hardened steels and materials with high hardness. They offer superior thermal stability and wear resistance.

Rust-resistant and with a cobalt build (five percent) to enhance heat resistance, these drill bits are ideal for dense and stubborn metal drilling.

In contrast to budget carbon steel bits, the HSS format includes additional elements such as vanadium, tungsten, chromium, or molybdenum.

Furthermore, always check that the shank of your bit kit is compatible with your hexagonal, round, or SDS chuck. Finally, look at the bit build material and design to verify it has the robustness to handle your workload and create the type of hole or countersink you require.Use our guide on buying and our ultimate top picks above to help you select one of the best drill bit kits!

‘Bit Diameter’ is measured in millimetres (mm) and refers to the size of the HSS drill bit you’re using. ‘Cutting Speed’ is measured in metres per minute (m/min) and can be sourced from the below table for the specific material you’re drilling.

Becoming a drill bit master is more than understanding their different types and applications — you also have to comprehend the material they’re made from and the shank format!

Coated Carbide Inserts: Coated carbide inserts are carbide inserts with a thin coating layer. The coatings, such as TiN, TiAlN, or TiCN, enhance wear resistance and extend tool life.

Gun drills are specialized deep hole drilling tools that consist of a carbide insert mounted on a long, slender shank. They are designed for drilling extremely deep holes with high precision. Key features and applicable ranges include:

These bits should be used in a drill press as they have no centre point to keep them steady and aligned. This also allows better control over the depth of the cut, as drilling down to the end of the cutter will mean prying the plug out with a small screwdriver.

Deep hole drilling inserts play a crucial role in achieving accurate and efficient drilling operations. Solid carbide inserts offer hardness and stability, while indexable inserts provide versatility and cost-effectiveness. Gun drills excel in drilling deep and precise holes. Manufacturers and machinists should consider the specific requirements of their drilling applications, such as hole diameter, material compatibility, and desired precision, to select the most suitable deep hole drilling inserts, ultimately optimizing productivity and achieving high-quality results.

Material compatibility: Suitable for drilling a wide range of materials, including steels, stainless steels, cast iron, and non-ferrous metals.

PCD (Polycrystalline Diamond) Inserts: PCD inserts feature a diamond layer on the cutting edge, providing exceptional hardness and wear resistance. They are suitable for drilling non-ferrous materials and composite materials.

When you need to power into concrete, masonry, and brickwork — you need a tungsten carbide tip. This phenomenally durable compound — formed from tungsten and carbon — exceeds the hardness of most steels and many ceramics.

For the bit to perform properly, it needs to operate at a very slow speed and be constantly supplied with water. Due to the design of these drill bits, the hole they bore may be just slightly larger than the stated size.

Stability: Solid carbide inserts provide high stability and rigidity, ensuring accurate and precise drilling operations.

These affordable and versatile sets give you a wide choice of bits to use and ensure material and drill-type stability — delivering effortless boring and keeping fatigue to a minimum.

These bits, commonly tipped with tungsten carbide, are designed mainly for hammer drills — allowing them to tackle tough materials like brickwork, cement, and stonework. Some professional-quality masonry drill bits also feature a hexagonal shank instead of a cylindrical shank to prevent the bits from slipping in the chuck.

To make the process effortless, and save you time searching multiple sites and products — I’ve selected my ultimate collection of drill kits to suit every individual preference and job type:

The most common shank type, they feature a cylindrical rod at the end of the drill bit, which fits into the chuck. It’s secured in the drill through friction — whether via a keyed or keyless chuck system.

Suitable for various materials: Gun drills can be used for drilling a wide range of materials, including steels, stainless steels, aluminum, and composites.

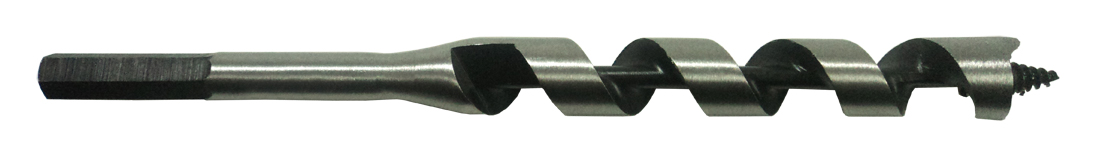

Auger bits are capable of drilling very large holes with ease and are designed only for drilling into thick, hard and dry timber. The screw thread at the tip draws the drill bit into the material — eliminating the need to push.

These bits for drills feature a brad point tip — resembling a W-shape — which guides the outer edges to precisely define the hole diameter before the centre point penetrates the material.

When operating power tools, personal protective equipment (PPE) must always be worn. Here is some more information on PPE and power tool safety.

Step drills almost take on a conical shape, but follow a staircase profile from a narrow point to a large base. This design allows you to buy just one drill bit and achieve multiple-size holes.

If you’ve ever browsed the aisles of your local hardware or home improvement store, the choice can be overwhelming and confusing. With a multitude of styles, materials, and sizes — it can be tough to know which set to choose, even for the experienced pro.

Long hole drilling: Gun drills can achieve hole depths up to 100 times the diameter, making them ideal for deep hole applications.

You can get your hands on sets that power into timber, metal, plastic, and drywall. Some drill bit kits may also have masonry bits for drilling into brickwork and concrete.

Identifiable by their gold colouring, these bits can tackle tougher materials than other HSS formats, offer greater durability, and reduce friction for cooler and easier boring. When they’re used correctly, the titanium nitride coating greatly extends the cutting life of these drill bits four-to-six times longer than conventional bits.

SDS format drill bits are the go-to choice for rotary hammer drills when tackling tough masonry projects. They feature unique shank designs with slots that enable quick bit exchanges and a secure fit during hammer and impact action.

Plug cutters are used to make timber plugs that fit into and conceal recessed screw holes in your soon-to-be varnished work. This is done by cutting the plugs out of a separate piece of the same timber you’re working with to preserve the colour and grain of the wood. The most common sizes are imperial — in ⅜, ½, and ⅝ inches.

Suitable for high-speed drilling: Solid carbide inserts can withstand high cutting speeds, making them ideal for high-production drilling.

Please note that the calculated speeds should only be used as a guide. Depending on various factors at work, including the specific grade of the material and cutting fluid availability, changes may need to be made to the calculated RPM. It’s best to start with a slower speed, observe the cutting action, and increase it if needed.

On the positive side, round shanks are compatible with virtually all corded and cordless drills and drivers. And, relatively inexpensive to manufacture, they’re reassuringly affordable. These aspects make them ideal for day-to-day drilling jobs in wood, plastic, and softer metals — and are perfect for DIYers and occasional users.

It gives you a close approximation of the required RPM (revolutions per minute) you must operate your HSS drill bit at for the best cutting results — in a range of different materials.

These additional ingredients permit the bits to withstand the high pressures, stresses, and temperatures experienced when driving at rapid speeds. While suitable for metals and plastics — they’re not ideal for masonry jobs, without a carbide tip.

There are some downers though. Compared to the more specialised formats, round shanks are more likely to slip under high torque. Furthermore, they’re less than perfect for high-impact projects such as hammering, demolition, and impact work — where the bit is liable to break.

They’re, therefore, perfect for drilling into wood and some plastics, and for jobs like dowelling. These drill bits will also sometimes come packaged with small rubber rings — called stops — that fit around the bit and allow you to choose the depth you want to drill to.

Spade bits, recognisable by their broad-point brad tip with angled spurs and a central spike — excel at creating large holes when drilling timber.

If the drill bit slips along the surface prior to drilling, simply scratch the surface of the tile or apply some masking tape. If operated carefully, a masonry drill bit may also be used (without a drill’s hammer mode engaged) in the same manner for this purpose, but it will not give you as smooth a finish.

Designed to overcome the challenges of drilling stainless steel, these M2 HSS drill bits feature a fast spiral, short flutes, and a unique stepped core — providing efficient cutting.

0086-813-8127573

0086-813-8127573