Nickel Alloys for Industrial 3D Printing - nickel alloys

Because of its versatility and toughness, nickel wire is an ideal choice for many applications. This material is highly valued for its strength, ductility, conductivity, and resistance to corrosion and extreme temperatures.

Nichrome is especially effective at heat and oxidation resistance, often serving as the heating element in household appliances like toasters and hair dryers. Ceramic sculptors, glassmakers, laboratories, and construction sites also use nichrome to heat objects.

KEGG Orthology (KO) [BR:dre00001] 09140 Cellular Processes 09142 Cell motility 04820 Cytoskeleton in muscle cells 64612 (atp1a1a.1) 09150 Organismal Systems

This formula is used to calculate the table feed per minute (feed rate) from the feed per tooth, the number of teeth, and the spindle speed. Example: Feed per tooth (fz) = 0.2 mm/toothNumber of teeth (z) = 8Spindle speed (n) = 600 min-1In this case, the table feed rate is 960 mm/min.

Nickel is a popular material for wires because its top layer can resist extreme chemical corrosion, including air and water oxidation. Nickel alloys are also resilient against acids and alkalis. Nickel wire is frequently used in products containing electrical components or those that experience high levels of heat (up to 2,600 °F). The material is also magnetic as long as it remains below 350 °F. Beyond this point, it will lose its magnetic properties.

SFM to RPM

12" Stainless Steel Machinist 4R Ruler/Rule Scale 1/8, 1/16, 1/32/ 1/64. Fine measurements on one side and easy to read large scale on the other. Warning ...

Composed of roughly two-thirds nickel, one-third copper, and trace amounts of iron, carbon, silicon, and manganese, Monel is stronger than pure nickel. Monel is also highly corrosion-resistant, especially in seawater. Therefore, this material is popular for marine and chemical processing applications.

At California Fine Wire, we manufacture wires based on your unique industry and application standards. We use only the highest quality raw materials and strive to exceed our customers’ expectations. We can insulate all our wire products with PTFE or enamel, and we can add a copper, gold, silver, tin, or extra nickel plating using our innovative electroplating capabilities. For more information about our products and services, contact us or request a quote.

PRODUCT AVAILABILITY · Hanson 9739 Hexagonal Die · Hanson 80213 Tap and Drill Bit Set · Hanson 8334 Straight Flute Plug Tap.

Hole cutters have individual carbide-tipped cutting teeth, similar to a circular saw blade. They generally have a thicker body and fewer cutting ...

resistance, the VP15TF prevents a failure of tool life even when machining hardened workpiece. aIntegrating the carbide technology and coating technology!!

Part Number: 13919-001 · Ensure you never run out of lab supplies and other essentials by using the subscription order feature. · Customers Also Bought These ...

This formula is used to calculate the feed per tooth from the table feed per minute (feed rate), the number of teeth, and the spindle speed. Example: Table feed per minute (vf) = 450 mm/minNumber of teeth (z) = 10Spindle speed (n) = 600 min-1In this case, the feed per tooth (f) is 0.075 mm/t.

Our Tooling types include the Ball Lock Punch, Head type Punch and Die or Matrix. Our Punches and Dies are manufactured to ISO and NAAMS Standards. Other ...

Adorable Chihuahua puppies await in Syracuse, NY! Personal pickups only, no shipping. Visit or contact us for a joyful puppy-buying experience.

Feedrate

A.D. International Radius Ball Turning Tool For 3/8" Shank With HSS Tool Bit. Material : High-Speed Steel (HSS) Tool Bit. The cutting tool bit is made from ...

Also known as nickel chrome, nichrome is a nickel and chromium alloy with varying levels of each metal. The number following the nichrome type indicates the proportion of nickel to chromium. For example, Nichrome 60 consists of about 60% nickel and 40% chromium.

TappingSpeed

Bengals head into Cheney and the final stretch of the season with newfound momentum. MARK LIPTAK FOR THE JOURNAL. If the college football season was like a ...

Pure nickel is one of the most valued metals in the world. Because of its superior malleability and ductility, nickel wires can be stretched to achieve thinness that would break other metals. Pure nickel wires are also excellent conductors of heat and electricity. For these reasons, nickel wires are used most commonly in the aerospace and medical industries.

This page introduces formulas for calculating basic parameters necessary for face milling. The figures obtained from the calculation are for reference only. The conditions for machining depend on the machine tool you are using. Use the optimal conditions according to your actual machining circumstances.

This formula is used to calculate the machining time from the total table feed length and the table feed per minute (feed rate). Example of finishing a block of FC200 cast iron to have a flat surface of: Width = 150 mLength = 250 mmFace milling conditions used: Feed per tooth (fz) = 0.35 mmNumber of teeth (z) = 12Spindle speed (n) = 200 min-1Cutting speed (vc) = 120 m/minFace mill diameter (D1) = 220 mmIn this case, the table feed per minute (vf) and the total table feed length (L) are:vf = 0.35 × 12 × 200 = 840 mm/minL = 350 + 220 = 570 mmSubstitute these values into the formula: Tc = L ÷ vf = 570 ÷ 1120 = 0.679 (min) × 60 = 40.74 (sec)The machining time (Tc) is approximately 40.74 seconds.

This formula is used to calculate the cutting speed from the spindle speed and the outer diameter of the cutter. Example: Cutter diameter (DC) = 100 mmSpindle speed (n) = 400 min-1In this case, the cutting speed (vc) is approximately 125.6 m/min.

This formula is used to calculate the net power required for face milling based on the depth and width of cut, the table feed per minute, the specific cutting force, and the machine efficiency. Example of calculating the net power required to cut tool steel with: Depth of cut (ap) = 5 mmWidth of cut (ae) = 70 mmTable feed per minute (vf) = 300 mm/min Other conditions: Specific cutting force (Kc) = 1800 MPaMachine efficiency (η) = 80% (0.8)Cutting speed (vc) = 80 m/minCutter diameter (DC) = 250 mmNumber of teeth (z) = 16 In this case, first you calculate the spindle speed (n) and then the feed per tooth of the cutter (fz). Spindle speed (n) = 1000・vc ÷ π・D = (1000 × 80) ÷ (3.14 × 250) = 101.91 min-1Feed per tooth (fz) = vf ÷ (Z × n) = 300 ÷ (16 × 101.91) = 0.184 mm/toothSubstitute the above into the formula: Pc = (5 × 70 × 300 × 1800) ÷ (60 × 106× 0.8) = 3.937 kwThe net power required for face milling (Pc) is approximately 3.94 kW.

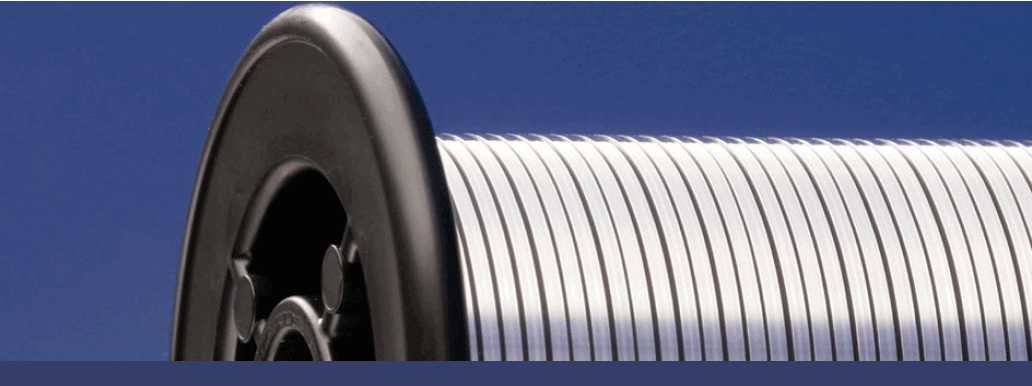

California Fine Wire manufactures high-quality custom wire products for a vast range of applications and industries. We can draw nickel wires to diameters as small as 0.0004 inch and offer various configurations, such as round, duplex, ribbon, or stranded. Our other wire materials include aluminum, copper, thermocouple alloys, gold, silver, platinum, and more.

0086-813-8127573

0086-813-8127573