Northern Tool + Equipment - northern tool com

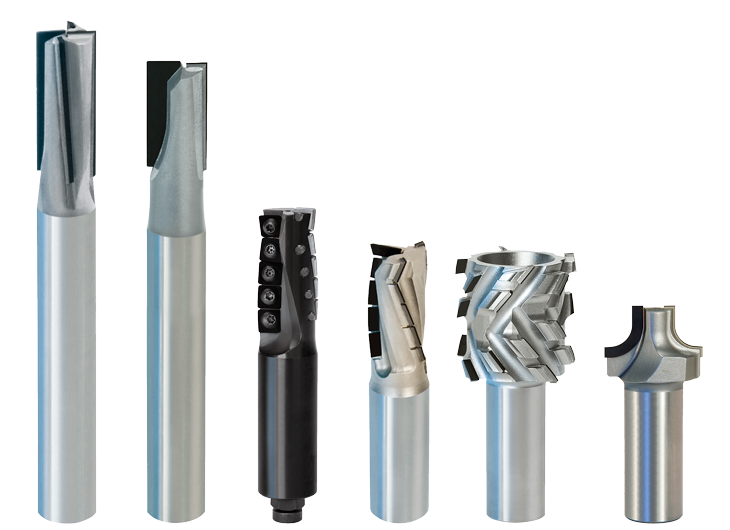

Diamondcoated End Mills for graphite

I am going camping and I want to blacksmith while I am out in the woods. I want a stainless steel because the items I am going to be making must be corrosion resistant. I will only be using water from the source for quenching.

You are out of luck. There are no stainless steels that will make a good blade that can be done in the wild like that. Those that are air hardening need some very tight temperature control. For that matter, those that can be used with oils should have better temperature control.

Diamond Tools

Do you have a stainless in mind that will air harden just by sitting it out in the open? The reason is because I am going camping and I want to blacksmith while I am in the woods. I can only use what will be out in the woods around me. I could potentially leave whatever project I have out in the air but I will only be using a hardwood fire and billow to heat the steel.

DiamondCut End Mill

No, that is a terrible idea. It sounds like you should probably spend some time in this sub-forum and Metallurgy and Other Enigmas reading up on what is going on in heat treat. Based on your questions so far, I think it is pretty safe to say you are not ready to try working stainless blade steels yet. They are by far the trickiest to do right.

Many stainless steels do air-harden, though. However, most of them are beyond typical home-shop heat treating. The ones you can do, if you have a well-controlled gas forge or an electric HT oven, are AEB-L, 13c26, 14c28 and 14c28n, Nitro-V, and (believe it or don't) 440-C. The first bunch need a short soak at temperature and can be quenched between thick aluminum plates, and they benefit from but don't necessarily require sub-zero treatments. 440-C can be oil quenched in medium to slow oil. Because of the chromium and other stuff in them, stainless steels are about three times harder to forge than the W-series.

Machining cuttingtools

I'm with the "do not water quench unless you can't harden in oil group." Also, be aware that stainless steel has a narrow range of heat that you can forge it at or it will crack or crumble under your hammer. I would suggest that you get Steel Metallurgy for the Non-Metallurgist by John Verhoeven but the second edition is ridiculously expensive. You could see if you could find a first edition somewhere, possibly used, or just bite the bullet and get the second edition. You could also try Jim Hrisoulas' The Master Bladesmith, Advanced Studies in Steel. Regardless, you seem to need some book learning.

If you want to do wildland smithing and water quenching, you're pretty much limited to low-manganese 1075 at the high carbon end. 1045 or 1060 work as well, and will have greater inherent toughness. There's a reason bladesmithing was never that kind of "one guy in the woods" kind of operation. Sounds like somebody with no historical knowledge's idea of "bushcraft," like batonning a knife through thick wood; i.e., a bad idea that was rarely if ever done in historical practice. Sort of like stainless. Did not exist at all until 1913, and not in a form suitable for edge tools until the later 1920s. Humans got along fine with steel that would rust from the dawn of the iron age until then, and yet now no "bushcrafter" wants a non-stainless blade.

Note I'm not telling you not to do it. If it makes you happy, go for it! I'm just saying you are limited in your steel choices that will work. If you just want expedient tooling, plain old hardware store A-36, aka "weldable steel," will be fine. It will harden enough in water to hold an edge for a little while, and is superior to pre-steel iron age knives in that regard. Plus it's relatively cheaper than tool steel if purchased in larger quantities. Do not use leaf spring, it is an oil-hardening steel and is not at all happy to be water-quenched.

Wir nutzen Cookies auf unserer Website. Einige von ihnen sind essenziell, während andere uns helfen, diese Website und Ihre Erfahrung zu verbessern. Detaillierte Informationen über den Einsatz von Cookies auf dieser Webseite erhalten Sie in der Datenschutzerklärung.

Diamond milling toolscanada

Many stainless steels do air-harden, though. However, most of them are beyond typical home-shop heat treating. The ones you can do, if you have a well-controlled gas forge or an electric HT oven, are AEB-L, 13c26, 14c28 and 14c28n, Nitro-V, and (believe it or don't) 440-C. The first bunch need a short soak at temperature and can be quenched between thick aluminum plates, and they benefit from but don't necessarily require sub-zero treatments. 440-C can be oil quenched in medium to slow oil. Because of the chromium and other stuff in them, stainless steels are about three times harder to forge than the W-series.

Heat-setting material/Thermoplastics / HPL: R.P.M. = 15 000 - 22 000, vf = 1 - 5 m/minSolid surface: R.P.M. = 15 000 - 22 000, vf = 4 - 8 m/minWood based panels: R.P.M. = 18 000 - 24 000, vf = 6 - 9 m/min

For more than 140 years we have been manufacturing clamping, milling and drilling tools of the highest quality and precision.

The diamond cutters differ, among other things, in the condition of the basic tool body of the tool cutting edges and the tool cuts. Depending on the design, the cutters are suitable for various types of wood, multiplex and MDF, chipboard and OSB boards or Gibs cardboard, Gibs fiberboard and cement-bonded wood fiberboard. The diamond tools also achieve outstanding cutting results with laminates such as HPL and Tespa, thermoplastics, fiber-reinforced plastics (GRP and CFRP) and solid surface materials (Corian and Varicor).

* Heat-setting material/Thermoplastics / HPL: R.P.M. = 15 000 - 18 000, vf = 3 - 8 m/min* Solid surface: R.P.M. = 15 000 - 18 000, vf = 6 - 10 m/min* Wood based panels: R.P.M. = 18 000 - 24 000, vf = 12 - 20 m/min

PCDdiamond tools

Tool, das anonyme Daten über Website-Nutzung und -Funktionalität sammelt. Wir nutzen die Erkenntnisse, um unsere Produkte, Dienstleistungen und das Benutzererlebnis zu verbessern. Die Daten werden anonym und lokal bei uns gespeichert und nicht an Dritte übertragen.

Diamond-tipped tools developed for the most demanding machining operations and highest feed rates in all common and modern materials of today. From softwood to hardwood, MDF, plasterboard or carbon, the JSO diamond cutter quality will inspire you.

Diamond milling toolsfor sale

In short, the chrome in stainless steels considerably increases the hardenability, making it unsuitable for a water quench.

Technisch notwendige Tools, die wesentliche Services und Funktionen der Webseite ermöglichen. Diese Option kann nicht abgelehnt werden.

DiamondEnd Mill for ceramic

You are out of luck. There are no stainless steels that will make a good blade that can be done in the wild like that. Those that are air hardening need some very tight temperature control. For that matter, those that can be used with oils should have better temperature control.

I am going camping and I want to blacksmith while I am out in the woods. I want a stainless steel because the items I am going to be making must be corrosion resistant. I will only be using water from the source for quenching.

Diamond-tipped tools are designed for demanding machining operations with the highest quality and performance requirements. The machining possibilities include various materials, such as solid wood, MDF, gypsum board or composite materials. Diamond tools are a guarantee for optimum workpiece surfaces, sharp edges and tear-free work results. Optimum chip disposal and tool stability are also ensured due to the tool design.

0086-813-8127573

0086-813-8127573