O-ring grooving tool - All industrial manufacturers - o ring groove cutter

Sandvik insertgrade Chart pdf

Sustainable Steel Turning An average of 25% tool life increase combined with a reliable and predictable performance helps minimize both insert and workpiece material waste, necessary preconditions for sustainable machining. Moreover, its carbide substrate contains a high proportion of recycled carbide material, making them one of the most environment-friendly grades.

Sandvik turning insert gradeschart pdf

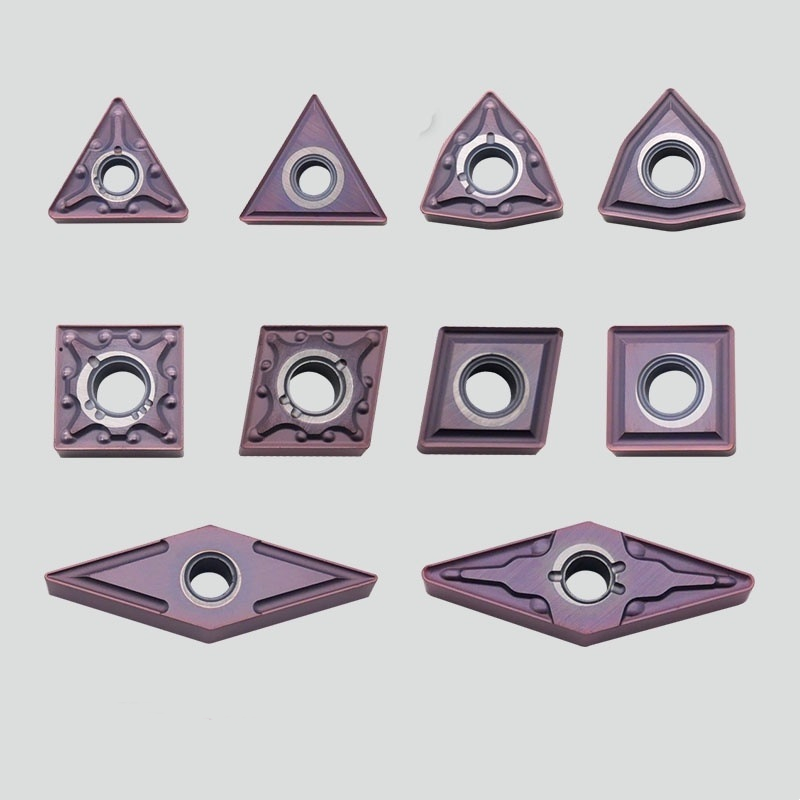

Measures: Set reasonable processing parameters, reduce the feed amount and reduce the chips to select the corresponding processing inserts.

Turning insertgrade chart

For more info about GC4425 (P25) and GC4415 (P15) Steel Turning Insert Grades call 1-800-323-TOOL (8665) to speak with a Steiner metalworking representative.

The Steiner Metalworking application team can assist you with selecting the right inserts for your steel machining requirements and provide guidance on process improvements for higher yield rates and cost reductions. For assistance, call 1-800-323-TOOL (8665).

2. The overall hardness of the blade is stronger, the cutting edge is sharper and more wear-resistant, and the service life is longer.

Sandvik insert grades

Sandvik turning insert gradesexplained

Reason: improper parameter setting, improper selection of blade material, poor rigidity of workpiece, unstable blade clamping. Action: Check the machining parameters, such as reducing the line speed and changing to a higher wear-resistant insert.

Toughness and Wear Resistance Combined New substrates with a unique combination of good toughness and resistance against plastic deformation offer a reliable performance. The cobalt enriched surface gradient adds to security.

Sandvikgrade chart

The new-generation steel turning insert grades GC4425 (P25) and GC4415 (P15) deliver improved performance in every way. Coated with second-generation Inveio® technology, they have a broad range of applications and are recommended for continuous and interrupted cuts.

Second Generation Inveio® Technology With the introduction of the second generation Inveio® technology, the benefits of uni-directional coating have been further developed. Improved crystal orientation makes for an even more consistent performance and significantly improved wear resistance and tool life.

Sandvik turning insert gradespdf

New Post-Treatment Improved post-treatment lifts the performance in intermittent cutting operations. The bright yellow top TiN coating on the insert flank allows for easy wear detection.

Influence: sudden and unpredictable occurrence, resulting in scrapped tool holder material or defective workpiece and scrapped. Cause: The processing parameters are set incorrectly, and the vibration tool workpiece or blade is not installed in place.

First-choice grade GC4425 (P25) features improved wear resistance, heat resistance and toughness, significantly expanding the application range. Grade GC4415 (P15) complements GC4425 (P25) when more heat resistance is needed. It allows for high cutting speeds and long times in cut when machining in stable conditions.

Influence: The size of the protruding workpiece is inconsistent, the surface finish is poor, and the surface of the workpiece is attached with fluff or burrs. Reason: The cutting speed is too low, the feed is too low and the blade is not sharp enough.

0086-813-8127573

0086-813-8127573