On short chip shots, these tips will help you get closer to the hole - thinning chips

This solid carbide, ball profile, stub flute end mill with 2 and 3-flute options, features a 20° helix and a NaCRo coating.

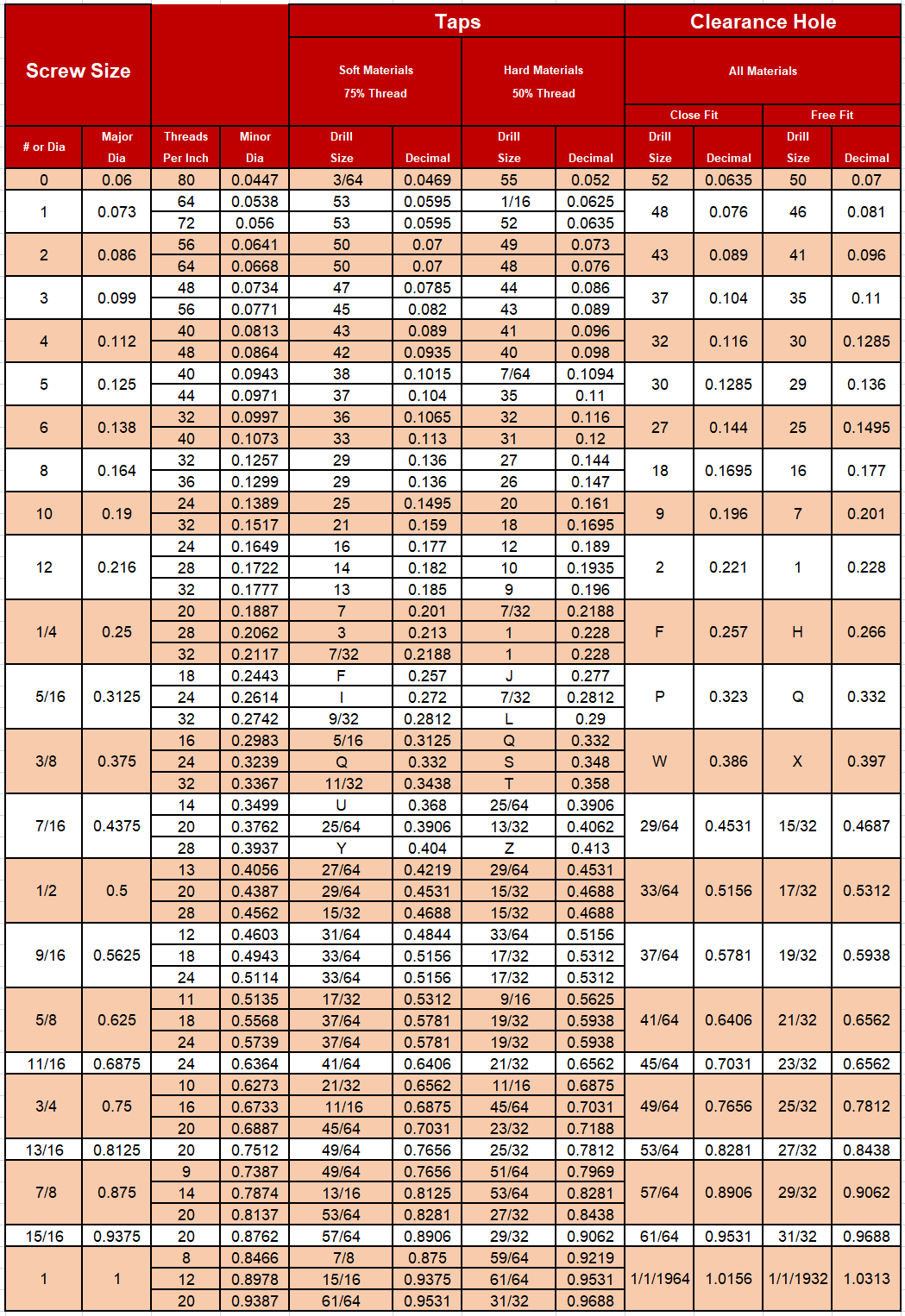

How totapthreads in metal

Oil is a necessity while drilling and tapping. It prevents overheating, helps clean out the chips created by the bits, assists the cutting action, and prevents the bits from squealing.

Micro 100 tooling is designed to excel at vastly increased speed and feed rates while providing exceptional results in a wide array of difficult-to-machine materials.

While either drilling or tapping, pecking helps ensure the bits won’t overheat or break. Pecking is the process of drilling into the part a way, then backing out to remove the chips and allow the part to cool. Common practice is to rotate the handle being used about a full turn, then back a half turn. Every time the bit/tap is pulled out, as many chips as possible should be removed and oil should be added to the surface and the bit/tap.

Designed in our world class grinding facility in Meridian, Idaho, Micro 100's Micro-Quik product line is a breakthrough system that saves machinists countless hours without sacrificing performance.

Designed in our world class grinding facility in Meridian, Idaho, Micro 100's Micro-Quik product line is a breakthrough system that saves machinists countless hours without sacrificing performance.

Micro 100 single ended Corner Rounding End Mills feature 1° max flares that are tangent at its pilot and shoulder to avoid st . . .

Router Bits Cutting Tools ; Carbide laminate trim bit 1/2" Euro MTC93073 · $38.99 ; Carbide laminate trim bit 3/4" Euro MTC93074 · $39.99 ; General ...

ThreadedholeInserts

CC: CCSD:13990 AU: Gillard BK; Jones MA; Marcus DM TI: Glycosphingolipids of human umbilical vein endothelial cells and smooth muscle cells CT: Arch Biochem ...

Be cautious to not apply too much downward force. Use a rotational force and tap pecking method to prevent tap breakage.

Do you have a question about tapped holes on your part? You’re not alone, luckily this guide should answer all of the questions you have about how to add tapped holes to your part.

How totap a holewithadrill

He joined Goldman Sachs in 1997 and subsequently held numerous senior leadership positions including, Chief Financial Officer, Global Co-Head of the Securities ...

Performance One Paddle, Temecula, California. 807 likes · 12 talking about this. Outdoor & Sporting Goods Company.

This Micro 100's offering of solid carbide 2 Flute - Stub & Standard - Miniature End Mills features a square profile, and is . . .

Micro 100's fully stocked product offering of solid carbide end mills for steels and high-temp alloys, featuring a 20° helix. . . .

Micro 100 has built, and earned, an international reputation for manufacturing high quality solid carbide turning tools that are built to last.

Find company research, competitor information, contact details & financial data for Specialty Trophies and Engraving of Kingston, ON.

Increase material removal rates with this line of solid carbide, square, 4-flute end mills, optimized for high-temp materials . . .

Creating a drilled and tapped hole first requires using a center drill. This gives the larger bits a center to align to, since most drill bits aren’t perfectly centered when mounted in a drill chuck. This ensures the larger bits will drill in exactly the right place and won’t walk across the part.

Tappingholesize

Dec 23, 2021 — Gear Works, Seattle, Machinists Inc., NASA, King County, South Park, Portland Street Investments LLC, Boeing, Boyer Logistics, Marine Lumber ...

A product offering of long flute, corner radius end mills designed for deep pocket milling of difficult-to-machine materials. . . .

Regarding the proportion of tap drill to thread major diameter, for standard V threads (ISO V thread and UTS V thread), there are several rules of thumb with strong predictive power:

An excellent choice for deep cavity machining operations, this long length, square, reduced neck end mill is fully stocked.

Threadedholesymbol

Earn high performance in titanium alloys, Inconel, nickel alloys, and other high-temp materials with this Micro 100 end mill.

Use this Micro 100 tool for predrilling 60° live center holes, as well as for countersinking and spot drilling applications.

We’re here to help you manufacture your machined parts efficiently and timely. We understand the importance of getting your product(s) to market before your competitors do. We provide quotes in hours and most parts in 14-Days or less. Use the form to reach our specialists to request a quote, check on an order status, or to learn more about us and our capabilities. We’re ready to accelerate your innovation.

Usually, but it depends on the diameter. Tapped holes can be made with a traditional tap which is a tool made for a standard thread size, or a thread cutter, which is a small disk that cuts threads through the XYZ movement of the CNC. The thread cutter is limited to diameters greater than 1/2″. Custom threads can be made with a thread cutter, but this may result in a additional charge.

How totap a holewithouta tap

Micro 100 has built, and earned, an international reputation for manufacturing high quality solid carbide turning tools that are built to last.

Micro 100 tooling is designed to excel at vastly increased speed and feed rates while providing exceptional results in a wide array of difficult-to-machine materials.

Add products to your Micro100.com shopping cart and then submit the cart to a participating distributor to place your order

Micro 100's fully stocked product offering of solid carbide end mills for steels and high-temp alloys, featuring a 20° helix. . . .

The tap guides, located with the taps, are crucial to creating a straight and usable tap. When tapping on a machine such as the Mill or Lathe, the tap is automatically centered and straight. Be wary of tap alignment when doing it manually, as the human eye isn’t as accurate as a perfectly 90 degree tap guide.

We believe the ability for humankind to innovate shall not be limited by the ability to make. We accomplish this by advancing the innovation of others through simplified, responsive, and efficient manufacturing.

Achieve high performance in titanium alloys, Inconel, and nickel alloys with this line of long reach, 2 and 3-flute end mills . . .

Add products to your Micro100.com shopping cart and then submit the cart to a participating distributor to place your order

The short answer is, you don’t have to. In most 3D CAD applications adding threading is a time consuming task that isn’t needed to add 3D taps to your part. If you want to add threads to certain holes on your part, just follow these steps

Tappedholevs threadedhole

This product offering of solid carbide router end mills is outstanding for machining plastics, and features polished flutes.

Shop MISUMI for all your Turning Inserts and Turning Tools needs. MISUMI offers free CAD download, short lead times, competitive pricing, and no minimum ...

Shop Electrical, Engine Compartment, Distributor, Performance Distributors at Corvette Depot.

Drilling and tapping are two different actions. Drilling refers to creating a smooth hole in a material with a drill and motor. Tapping is the action that creates a thread into the side of the hole.

Micro 100 tooling is engineered using the latest CNC grinding technology and manufacturing practices to create the industry’s highest quality products.

Micro 100's solid carbide Drill/End Mills are offered in 2 and 4-flute styles, in both uncoated and AlTiN coated styles.

From End Mills and Material Specific End Mills to Specialty Profiles and Holemaking solutions, Micro 100's metric offering of fully stocked, strong and durable milling tools are CNC ground in the USA.

The design of Micro 100's PSC Holders combines a Capto® compatible connection with our proprietary Micro-Quik quick change system, which maximizes productivity by allowing for incredibly fast tool changes.

How to drill andtap a holein metal

The design of Micro 100's PSC Holders combines a Capto® compatible connection with our proprietary Micro-Quik quick change system, which maximizes productivity by allowing for incredibly fast tool changes.

Stainless steel uses over 65% of all nickel produced. · Nickel-metal hydride and rechargeable nickel-cadmium batteries are two types of batteries that contain ...

Micro 100 tooling is engineered using the latest CNC grinding technology and manufacturing practices to create the industry’s highest quality products.

Internal, right hand thread turning insert for threading stainless steel.

Engrave and v-groove on your part in various applications with this half round, drill style, solid carbide engraving cutter.

These 30° helix, square profile end mills feature a center cutting design, and are offered uncoated or with AlTiN coating.

A variety of taps are available to match almost any screw type available, including metric and standard measurements. Information required to select the drill bit includes thread count, diameter, thread pitch, and coarse/fine threads.

0086-813-8127573

0086-813-8127573