On the Unique Microstructure and Properties of Ultra-High ... - high carbon steel microstructure

Sandblastingis a mechanical surface finishing process used in various industrial sectors to clean, smooth, or prepare surfaces through the abrasive...

Uses offeedmill

However, if you are still in doubt, the recommendation is to consult an expert. Do not hesitate to contact us, we will be more than glad to help you!

Aluminium 7075 is well-known for its excellent fatigue strength. This alloy has better corrosion resistance than the aluminium 2000 alloys. Most times, machine operations are conducted using oil lubricants.

Given the properties, you should consider this aluminium alloy whenever exposure to the types of environments above is not avoidable. Another important factor to select is the need for high mechanical strength and fatigue resistance, as long as the part does not operate at very high temperatures.

Animalfeedmill

Our expansive range of high feed milling solutions meets all application needs. Plus, with the help of Seco’s knowledgeable and experienced team, you can seamlessly implement high speed milling techniques to increase your productivity and competitiveness.

The primary element found in the 7075 aluminium alloy is zinc. With zinc as the top alloying element, this aluminium grade obtains a series of properties that make it suitable for a wide variety of applications.

Aluminium has become a very popular material for applications across many different industries and in CNC machining. Its popularity over other materials is associated with its excellent mechanical properties. If you want to learn all about the top 3 aluminium alloys, keep reading as we disclose all the details.

In helical interpolation, high feed milling is suitable for making large-diameter holes because it often means skipping pre-machining or pre-drilling. It’s also commonly used for plunging operations, especially when machining difficult materials such as titanium and other light alloys.

This is the strongest alloy in the 6xxx series, and it is often called structural aluminium alloy since it is very popular for structural components.

High feed milling is a milling method that permits up to three times faster machining than conventional methods.STAY UPDATED ON ALL NEWS AROUND HIGH FEED MILLING!PLEASE CLICK HEREIt pairs shallow depth of cut with high feed per tooth which gives higher metal removal rates and results in more parts being machined. The cutting forces are directed at the machine spindle in the axial direction, which means greater stability and reduced vibrations, extending tool life. Additionally, high feed milling tools save time by avoiding semi finishing and reducing tool changes.Our expansive range of high feed milling solutions meets all application needs. Plus, with the help of Seco’s knowledgeable and experienced team, you can seamlessly implement high speed milling techniques to increase your productivity and competitiveness.Face milling with the high feed milling method is perfect for creating a good platform for further machining operations or a final finishing. In most applications, you’ll often get such fine tolerances that only final finishing is needed.High feed milling is also very practical for copy mill machining uneven surfaces and is highly effective in cavity milling and creating molds and dies. With copy milling and cavity milling, the application indicates the necessary tool diameter, making selecting the right tool easy.In helical interpolation, high feed milling is suitable for making large-diameter holes because it often means skipping pre-machining or pre-drilling. It’s also commonly used for plunging operations, especially when machining difficult materials such as titanium and other light alloys.

Feed millingtechnology

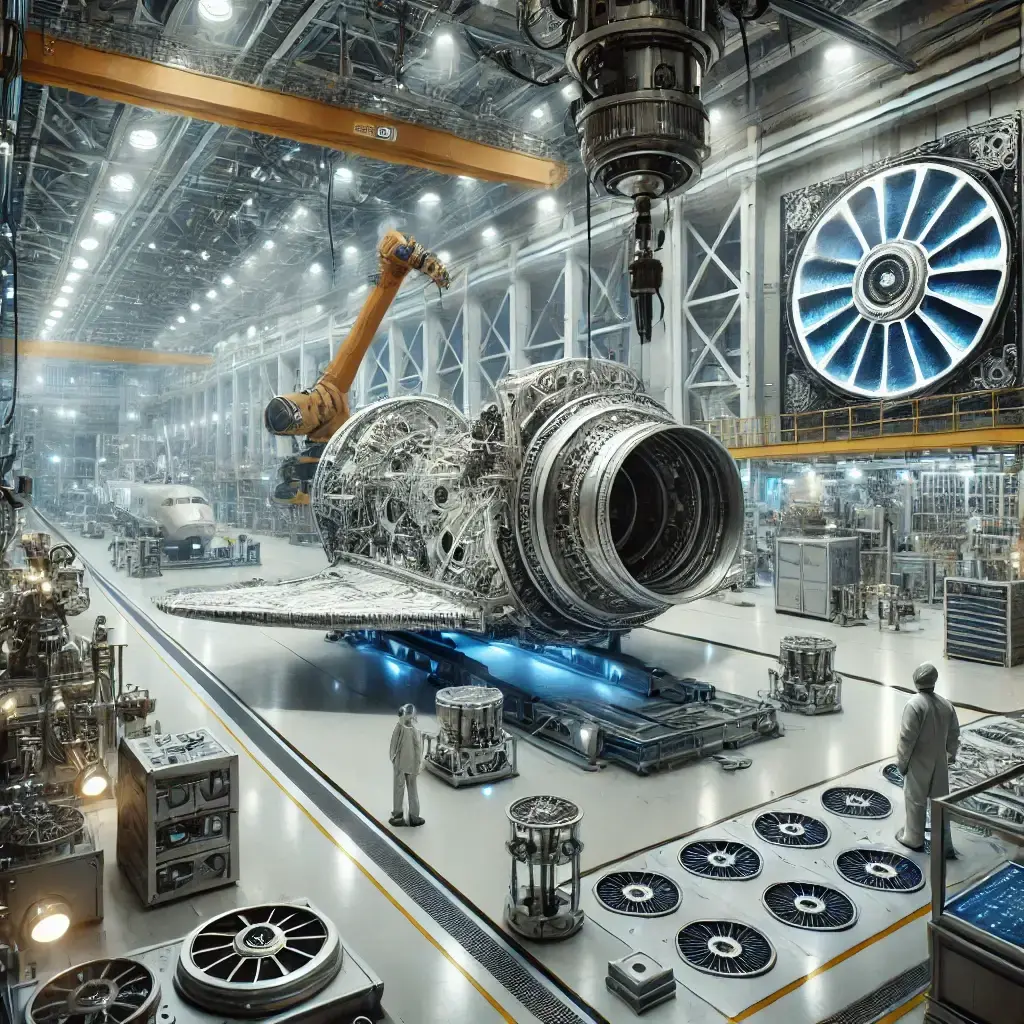

The aerospace industry stands as one of the most technologically advanced and complex sectors. Here, precision, reliability, and resilience are not...

The 5083 alloy is also exceptional for welding since it does not lose strength during the process. In addition to a very high resistance, it is recommended for use at temperatures up to 600°C.

Feed millingprocess

The 7075 aluminium alloy is a great solution for applications that require lightweight components with the highest level of strength possible. Also, the 7075 aluminium alloy allows to achieve very complex geometries with high precision. Common applications for 7075 aluminium parts include but are not limited to:

Feedmill process flow chart

Because of the cost, you should only use it if your specific application requires the essential features of this alloy. Otherwise, you may be better off with a cheaper alloy.

It pairs shallow depth of cut with high feed per tooth which gives higher metal removal rates and results in more parts being machined. The cutting forces are directed at the machine spindle in the axial direction, which means greater stability and reduced vibrations, extending tool life. Additionally, high feed milling tools save time by avoiding semi finishing and reducing tool changes.

There are a number of aluminium alloys in the current market. Yet, we truly believe there are 3 that excel above the rest for most applications. These are aluminium 7075, aluminium 5083, and aluminium 6082. Let’s see each of them in more detail.

Feedmill operation PDF

The aluminium 5083 alloy is popular due to having exceptional performance in extreme environments, such as exposure to seawater and industrial chemical environments.

Face milling with the high feed milling method is perfect for creating a good platform for further machining operations or a final finishing. In most applications, you’ll often get such fine tolerances that only final finishing is needed.

The main reason for this alloy to be so strong while having very high corrosion resistance is that it contains a large amount of manganese which controls the grain structure, thus making it more stable.

As it was mentioned above, the aluminium 5083 alloy is excellent in applications that require resistance to harsh environments. Therefore, the main applications for this alloy are associated with that aspect.

Feedmill Manager

This is an aluminium alloy that accepts different types of treatments after machining. The most common treatments include heat treatment, annealing, and ageing. However, anodizing is not a possible treatment after machining 7075 aluminium.

One of the main reasons for using aluminium across different industries is that it is lightweight, ductile, and malleable.

Perhaps the only negative characteristic of the aluminium 6082 alloy is that thin walls are difficult to machine as well as complex shapes are difficult to achieve via extrusion. Also, while it accepts welds, it is important to consider that the welded zone will lose strength.

Aluminium recycling is one of the most efficient and environmentally sustainable industrial processes, playing a crucial role in waste management and...

FeedMill Machine

High feed milling is also very practical for copy mill machining uneven surfaces and is highly effective in cavity milling and creating molds and dies. With copy milling and cavity milling, the application indicates the necessary tool diameter, making selecting the right tool easy.

The aluminium 6082 alloy is very versatile, and it also accepts different treatments to make it even more suitable for specific cases.

We already mentioned that the aluminium 6082 alloy is widely used in structural components such as trusses and bridges. But of course, this could not be the only application for a material with such properties as those mentioned above. Machinery components are also commonly made with this aluminium alloy.

0086-813-8127573

0086-813-8127573