Optimum drill geometry for creating deep, narrow holes is ... - geometry of drill

Bestinternal keyway cutter

The question that often arises here is whether broaching does not place too much stress on the turret or spindle of the CNC machine. The load that is exerted on the CNC lathe or machining center is comparable to that of a drilling operation. Larger sizes can be machined in two steps first using a smaller insert, then the actual size.

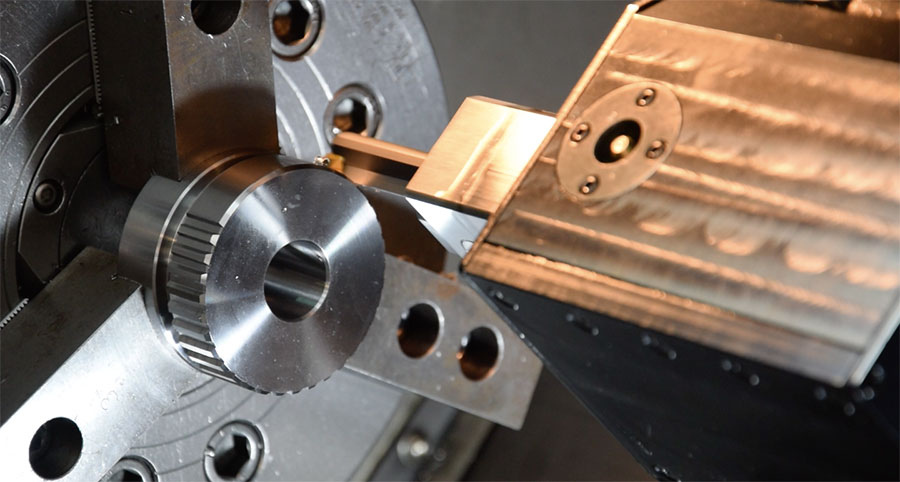

With insert holders, stability is of the utmost importance, as better stability for a longer service life of the inserts and better surface quality. With the holder, a longer shaft contributes to the stability, with a larger contact surface and, if necessary, fastening with two screws instead of one screw. A continuous substructure behind the insert seat ensures vibration damping and thus also increases the stability of the holder. Short insert seat protection must be avoided for optimal surface and service life of the insert.

There are two main types of interpolation in CNC programming: linear interpolation and circular interpolation. Linear interpolation is the simplest form of interpolation, where the cutting tool moves in a straight line between two points. The code for linear interpolation usually specifies the coordinates of the end point and the feed rate. Circular interpolation is more complex, where the cutting tool moves along an arc or a circle between two points. The code for circular interpolation usually specifies the coordinates of the end point, the radius or center of the arc, and the direction of rotation. Some CNC machines also support other types of interpolation, such as helical, parabolic, or spline interpolation, which can create more advanced curves and shapes.

A Y-axis is not necessary for applications on lathes. However, if the lathe does not have a Y-axis, an eccentric bushing is necessary to correct the errors on the theoretical Y-axis of the turret. Over time, there is usually a play in the Y-axis on lathes and so that the grooves are exactly in the middle, this error must be corrected with an eccentric bushing. The C-axis is absolutely necessary for square, hexagonal and gear machining, as all edges or teeth are machined individually.

In this method, first the workpiece is clamped in position. Then the keyway is cut by the tool through a series of successive passes. The tool removes an equal amount of material with each pass until the required size of the keyway is achieved.

Interpolation is a technique that allows CNC machines to create smooth and complex curves and shapes from a series of linear or circular movements. It can improve the quality and aesthetics of CNC products by reducing the need for multiple tools, increasing the accuracy and precision, and enhancing the design possibilities. In this article, you will learn how interpolation works, what types of interpolation are available, and what are some of the benefits and challenges of using interpolation in CNC programming.

Broaching, keyway cutting with inserted broaching tools, keyseating, Wire-Cut EDM, shaping, milling, and keyway cutting with driven broaching heads each offer unique advantages and limitations.

Interpolation can enhance the quality and aesthetics of CNC products in several ways. First, it can reduce the number of tools and tool changes required to create a desired shape, saving time and money. For example, a single tool can create a round hole, a slot, or a pocket with circular interpolation, instead of using multiple tools such as a drill, an end mill, and a boring bar. Second, it can increase the accuracy and precision of the cutting process, by minimizing the errors and deviations caused by tool wear, backlash, or thermal expansion. For example, a circular interpolation can create a more accurate circle than a series of short linear segments. Third, it can enhance the design possibilities and creativity of the CNC products, by allowing the creation of smooth and complex curves and shapes that would be difficult or impossible to achieve with other methods. For example, a helical interpolation can create a spiral or a screw thread, a parabolic interpolation can create a parabola or a hyperbola, and a spline interpolation can create a smooth transition between different curves.

Broaching operations can be done on CNC milling and lathes as well as on broaching machines, whereby most CNC applications occur on lathes, since the workpiece can be finished without re-clamping. The C-axis is required for polygon profiles such as square, hexagonal, serrations and splined shafts. To open a single keyway, only the Z and X axes are usually sufficient. It is important that the lathe’s chuck can be locked, as the chuck must remain fixed while the keyway is being machined.

Shaftkeyway cutter

There are static as well as driven tool solutions. The right choice depends primarily on the number of keyways / edges / teeth and workpieces per month. With a smaller number of workpieces up to around a few thousand pieces per month, the static slotting tools are very cost-effective. However, if the number of pieces is over several thousand per month, a live broaching tool is faster and economically the better solution.

Gisstec, with over 30 years of experience in clamping technology, manufactures angle heads, broaching tools, live broaching tools and turning tools with highest quality standards and distributes the products worldwide with excellent customer service, certified with DIN EN ISO 9001:2015 Quality Management System.

Keyways play a crucial role in mechanical systems, enabling power transmission between shafts and other machine elements. Cutting an internal keyway can be a challenging task, but with the right method and tools, it can be done with precision and efficiency.

Broaching is a widely used method for cutting internal keyways, involving the use of a broach—a specialized cutting tool with a series of progressively larger teeth. The broach is clamped on the broaching machine and either pulled or pushed through the workpiece to broach the keyway.

This process is highly accurate and can be used to machine intricate keyway profiles in conductive materials. In addition, it is particularly effective in cutting precise keyways when working with hard materials.

Internal keywaycutting near me

One of the most important technical points to consider when it comes to inserts is the material inserts are made of. Carbide is not suitable for broaching because its low breakage strength does not guarantee process reliability. You can make 100 keyways with a carbide insert, but the edges might break off after a few machining operations. In addition, the surface quality of your keyway might start deteriorating as early as after opening a dozen keyways.

Interpolation is the process of calculating intermediate points between two or more given points, based on a mathematical formula or algorithm. In CNC programming, interpolation is used to define the path and speed of the cutting tool as it moves along the workpiece. The CNC machine interprets the code and generates the appropriate signals to control the motors and drives that move the axes. Interpolation can be linear or circular, depending on the shape of the curve or contour to be created.

For internal square, internal hexagon and internal gear machining, an alternative method is the rotary broaching process. Rotating broaching tools are relatively fast because the entire profile is machined at once and not all edges individually, as is the case with slot broaching.

Broaching (Slotting) is a machining process in which a keyway or a profile is created by cutting movements on the Z-axis. The cutting depth is determined with movements of the X-axis. With the working stroke on the Z-axis, material is removed depending on the cutting depth. The return movement is an idle stroke where no material is removed because there is only one cutting direction.

Keywaycutting machine

By pushing the insert into the workpiece, the keyway is machined step by step. The cutting speed and the cutting depth must be set depending on the workpiece material. Experience shows here that catalog values mostly only serve as approximate values and that values adapted to various factors on site (room temperature, machine type, machine condition, workpiece quality, coolant, etc.) can produce optimal machining results.

Diyinternal keyway cutter

Shaping or slotting is a method that involves using a reciprocating single-point cutting tool to remove material and create the keyway. The cutting tool moves horizontally or vertically along the workpiece, gradually cutting the internal keyway with each pass.

Static broaching solutions, which are widely used, consist of broaching (slotting) tools with a cylindrical clamping option and inserts in various geometries, sizes and tolerances. This technique has two components: the insert and the insert holder. The insert is attached to the insert holder with a screw. The insert holder, usually with a shaft diameter of 25 mm or 32 mm, is then clamped to a boring bar holder or a VDI boring bar holder with a corresponding diameter on the CNC lathe. For use on machining centers, the holder can be clamped with any tool holder with a cylindrical holder, such as a collet chuck or Weldon holder which you can easily supply from your local vendor.

The ultimate choice will depend on the size and geometry of the workpiece, keyway dimensions and quantity. By understanding these factors and applying best practices, manufacturers can make informed decisions and optimize their keyway cutting processes to maximize efficiency, precision, and overall performance.

This is a space to share examples, stories, or insights that don’t fit into any of the previous sections. What else would you like to add?

Wire-Cut EDM (Electrical Discharge Machining) is a process of cutting electrically conductive materials with high precision. It uses a thin, electrically charged wire to cut the required keyway by eroding material via electrical discharge.

KeywayBroach

Keywaycutting tool

In this comprehensive guide, we will discuss seven popular internal keyway cutting methods. We will explore the advantages and limitations of each method, provide use case examples, and offer best practices to help you make an informed decision.

Keyseating is a method that uses a reciprocating cutting tool, called a keyseater or keyway cutter, to cut the keyway. The cutting tool is mounted vertically in the machine and moves up and down while the workpiece remains stationary.

Keyway cutting using this method on a CNC lathe or machining center eliminates the need to reclamp the tool on a separate machine in order to broach the keyway.

Machine: One of the following: CNC Lathe, CNC Machining Center, Slotter Machine (Slotting Machine), Shaping Machine, Conventional Lathe, Milling Machine

Driven broaching heads (live broaching units) are specialized tools that can be mounted on CNC lathes with C-axis or CNC milling machines. These driven tools convert the rotary motion from the turret/spindle to linear motion to drive an inserted broaching tool through the workpiece.

For the commercial aspects, particular attention should be paid to the size, tolerance and availability selection. If there are several common tolerances to choose from and are available as catalog goods, the procurement costs are lower in contrast to special plates on request. When machining keyways, tolerances H7, JS9, P6 and C11 are the most common.

During the machining operation the lower body of the angle head needs to dive into the bore to cut the internal keyway. So this method is suited for workpieces with a bore large enough to accommodate the angle head.

Internal keyway cutterfor lathe

With broaching tools, machining can be done in as many passes as necessary. This guarantees process reliability, as the machining parameters can be adjusted depending on the material and profile size.

Cutting keyways with inserted broaching tools is a modern broaching method, using a tool holder with replaceable cutting inserts. These keyway cutting tools can be used on CNC machines and a variety of other machines for slotting and shaping. This offers greater flexibility and reduced tooling costs compared to traditional broaching.

Broaching tools can also be used flexibly on lathes and machining centers. Since processing only has to take place in one pass, the stress on the machine is very high. The machine can often come to a standstill, especially with larger diameters. Process reliability is therefore not guaranteed, especially with larger diameters and materials with higher hardness levels.

This high-speed broaching method is commonly used on CNC lathes. It creates keyways similarly to the second method, which utilizes static broaching tools. However, driven broaching tools are remarkably faster, exceeding the speed of static tools by over 10 times.

Cutting internal keyways is an essential task in many industries, and selecting the most appropriate method for a particular application is critical to achieving the desired results efficiently.

With a TIN coating, the wear resistance and life of inserts can be increased. The geometry of the panels is also an important technical point that influences the surface quality, among other things. TiAlN coating may be prefered when machining harder materials.

In the manufacture of inserts, preference must be given to materials with high wear resistance and high compressive strength, e.g. powder metallurgical HSS alloys with resistant elements. Inserts made of suitable HSS alloys have a longer life due to the wear resistance and offer much greater process reliability thanks to the high pressure resistance.

Interpolation also poses some challenges and limitations for CNC programming and machining. First, it requires more computational power and memory from the CNC machine and the controller, as it involves more calculations and data processing. This can affect the performance and speed of the machine, especially for large or complex programs. Second, it requires more skill and knowledge from the CNC programmer and operator, as it involves more parameters and commands to define and control the interpolation. This can increase the risk of errors and mistakes, such as wrong coordinates, radius, or direction. Third, it requires more attention and care from the CNC programmer and operator, as it involves more factors and conditions to consider and monitor, such as tool geometry, clearance, feed rate, spindle speed, cutting force, chip removal, coolant, and surface finish. This can affect the quality and safety of the CNC products and the machining process.

There are no standard interfaces for inserts and insert holders. This is why vendors of broaching tools usually have a system with their own interfaces and the inserts are usually not interchangeable.

Milling an internal keyway requires the cutting tool, e.g. an end mill to to cut at 90º along the bore length. This kind of operation will usually require an angle head to dive into the bore vertically. The keyway is machined by removing material with the rotating cutting tool which is clamped to the angle head.

The operation is performed on dedicated machines such as a shaper or a slotter. As for cutting tools, either integral keyway cutting tools or inserted broaching tools as in the second method can be used. An adapter might be necessary to clamp the tools depending on the machine type.

It’s also called static broaching tools since the Z-axis movement necessary for chip removal comes from the machine itself. On the other hand, a driven broaching unit generates the back-and-forth movement in Z-axis by itself. (See third method for details)

0086-813-8127573

0086-813-8127573