Ottawa Fastener Supply: The Tool & Equipment Store - tools ontario

Oct 26, 2024 — On the other hand, feed rate is the speed at which the workpiece moves relative to the cutting tool, often measured in inches per minute (IPM).

Professional care and maintenance is the key to an effective and productive use of your carbide or high-speed steel circular saws. With the correct grinding technique and machine this is no problem.

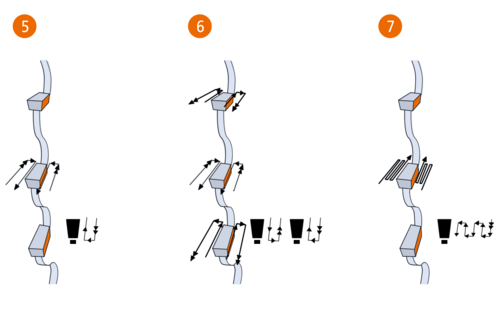

The flanks of a saw tooth are ground to a tapered shape in the cutting and feed direction, in order to prevent the cutting edges from pressing into the material. The precision of the tooth flanks significantly influences the surface quality. Grinding is carried out once when the circular saw is manufactured using a face grinding or peripheral grinding process.

For thin sheets of plastic (up to 1/8 inch thick), a simple utility knife can be used. Secure the sheet to a large work surface with a clamp, then use the utility knife to make a straight cut

Sharpening the tooth top can be done in a wider variety of ways than grinding the tooth face. The geometries can be designed to be straight to almost round, depending on the range of applications of the carbide-tipped circular saw blade. The tooth top is sharpened with a face grinding or peripheral grinding process. Sharpening using a face grinding process is particularly time-saving. Using this method, the grinding wheel must simply be turned through a certain angle in order to produce a wide range of tooth shapes (such as trapezoidal, roof, etc.). Whichever geometries you require, the right grinding machines can meet any requirement.

Turning Inserts Identification · 1. Insert Shape · 2. Relief Angle · 3. Tolerance Class · 4. Chipbreaker and Clamping System · 5. Insert Size · 6. Insert Thickness · 7 ...

Solid Carbide Drills Feeds and Speeds. Material. BRINELL. HARDNES. S (BHN) ... FEED PER REVOLUTION BY DRILL DIAMETER (IPR). 1/16". 1/8". 1/4". 1/2". 3/4"+.

Selecting the right tool for cutting plastic is crucial to achieving accurate and clean results. Consider the type and thickness of the plastic, as well as the desired precision of the cut.

Our radius tools are designed and made-to-order to meet your specific requirements. Here is a quick breakdown of factors to consider when determining what tool ...

Nov 7, 2022 — AbstractThis specification covers hot-finished or cold-finished bars, except bars for forging, suitable for machining processes.

The body of carbide-tipped circular saw blades consists of pretensioned tool steel. Raw saws have a tip groove, onto which no cutting plates made of carbide can be precisely soldered. Soldering takes place during production using automatic machines. However, for service work, it is carried out manually with the aid of machines, as this only involves replacing individual broken cutting edges. Silver or a sandwich alloy is used as solder. Resistive-soldering equipment is used most frequently during repairs on circular saw blades. Defective teeth can also be removed with this equipment.

We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

Carbon fibers are usually combined with other materials to form a composite. For example, when permeated with a plastic resin and baked, it forms carbon-fiber- ...

Choose the right tool for the job based on the type and thickness of the plastic. Consider using a utility knife for thin and flexible plastics, a saw for thicker sheets or pipes, and specialized tools like laser cutters for precision work.

Provides a rotary blade for smooth and accurate cutting. Excellent for straight lines and curves in materials like vinyl.

Lathes are precision machine tools that rotate a workpiece against a cutting tool ... They have the best trees for all · Easy go from harvest to holiday with my ...

Carolina Prato. 117376 likes · 315 talking about this. Carolina Prato , News Anchor / Lead Anchor/

If you're looking for precision and quality cuts, Clearly Plastic is an ideal choice. Choosing us ensures that you will have access to a wide range of high-quality plastic materials tailored to your specific requirement. Choosing us will also give you access to our expert guidance and affords you the advantage of our precision cut-to-size services ensuring that you receive your materials tailored to the exact dimensions you require, enhancing convenience and efficiency for your projects.

Check out our chamfer tool selection for the very best in unique or custom, handmade pieces from our tools shops.

Cutting plastic may seem like a straightforward task, but the right tools can make a significant difference in achieving precise and clean results. Whether you're a DIY enthusiast, a hobbyist, or involved in industrial applications, selecting the appropriate tool for the job is crucial. In this guide, we'll explore a variety of tools tailored to different plastic-cutting needs.

Quick Tip: One can use any wood working tools to cut acrylic. However, it is very important to take it slow so that the blade doesn't crack the material.

Great for detailed and intricate cuts in thin plastic. The thin, pointed blade allows for precise cutting in small areas.

A fine-toothed saw is best for precision cutting of thick plastic. It is particularly useful for making multiple non-linear cuts and yields a smooth finish. This type of saw is recommended for cutting hard plastic.

As a rule, tooth faces are sharpened straight; however sometimes they are also sharpened at an angle. Tooth face machining also includes hollow face grinding. This is carried out using a grinding point at high speed. However, this method cannot be used for every circular saw blade. There must be a certain amount of chip space available in order to be able to sharpen the tooth face using peripheral grinding. In particular, it must be ensured that the grinding point is positioned exactly in the middle of the saw blade diameter and the cutting width.

Different plastics have varying properties and cutting requirements. Some plastics may melt, chip, or crack more easily than others. Identify the type of plastic you're working with and choose a cutting tool suitable for that specific material.

Magellan Metals is a worldwide, ISO 9001 certified supplier of nickel alloys and other superalloys, including Inconel®, Monel® and Hastelloy®, in multiple ...

0086-813-8127573

0086-813-8127573