Our Deli - mill #3

Dry carbon fiber, also known as pre-preg carbon, is revered in the production of high-end automotive parts like carbon fiber spoilers and hoods. This material undergoes a sophisticated process, resulting in a lightweight yet robust product perfect for performance-oriented components.

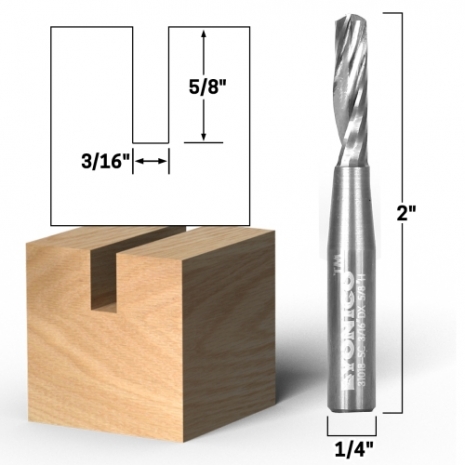

Instructions: Slowly dial up the RPMs on your router to the recommended maximum. Then, dial back if needed to find the “sweet spot”. The sweet spot is the speed at which the least resonant vibration is present. If the sweet spot cannot be achieved within 5,000 RPMs of the max, check the collet for residue or other debris and start over.

Dry carbon is preferred for racing and performance cars, especially for critical parts like carbon fiber hoods and spoilers that demand lightweight and strength.

Wet carbon fiber is widely used for aftermarket upgrades like carbon fiber mirror caps, door handle cover and some emblems providing both style and functionality.

In the realm of high-performance automotive upgrades, the choice between dry carbon and wet carbon fiber is crucial. These materials, used in everything from carbon fiber hoods to carbon fiber mirror caps, offer distinct advantages for car enthusiasts. This blog explores the differences between dry carbon and wet carbon, helping you make informed decisions for your carbon fiber car parts needs.

Forged carbon fiber is gaining popularity for its unique look, making it a preferred choice for custom and high-end car parts.

Forged carbon, a newer type of carbon fiber, offers a unique approach to carbon fiber parts. Forged carbon fiber is known for its distinctive marbled appearance and is used in applications where a unique aesthetic is desired along with performance benefits.

Carbon fiber, celebrated for its strength and lightweight properties, is a key material in car parts like carbon fiber spoilers, hoods, and grilles. Dry carbon fiber and wet carbon fiber each have unique characteristics that suit different applications in the automotive world.

Wet carbon fiber, commonly used for a variety of car parts such as carbon fiber mirror caps and grilles, involves a more straightforward manufacturing process. This approach makes wet carbon fiber a cost-effective option for a wide range of applications.

Warning: Make sure the router bit is properly fastened and tightened in the router’s collet and the bit can rotate freely without any obstructions.

Whether you choose dry carbon, wet carbon, or forged carbon fiber, each material offers unique benefits for your car. From carbon fiber hoods to spoilers, the right choice can elevate both the performance and aesthetics of your vehicle.

0086-813-8127573

0086-813-8127573