Parker AS568 O-Rings Size Chart - parker o rings catalog

Specialty Steel Supply Inc. is one of the largest distributors of austenitic, precipitation hardened, duplex and martensitic stainless steels. We have a wide range of products and types of stainless steel round bar and our well trained staff offers many years of experience in all aspects of the steel industry. Our ability to procure and source metals from all parts of the world allows us to stay competitive in a global marketplace. We are committed to developing and servicing just in time inventory programs.

Steel cobaltfor sale

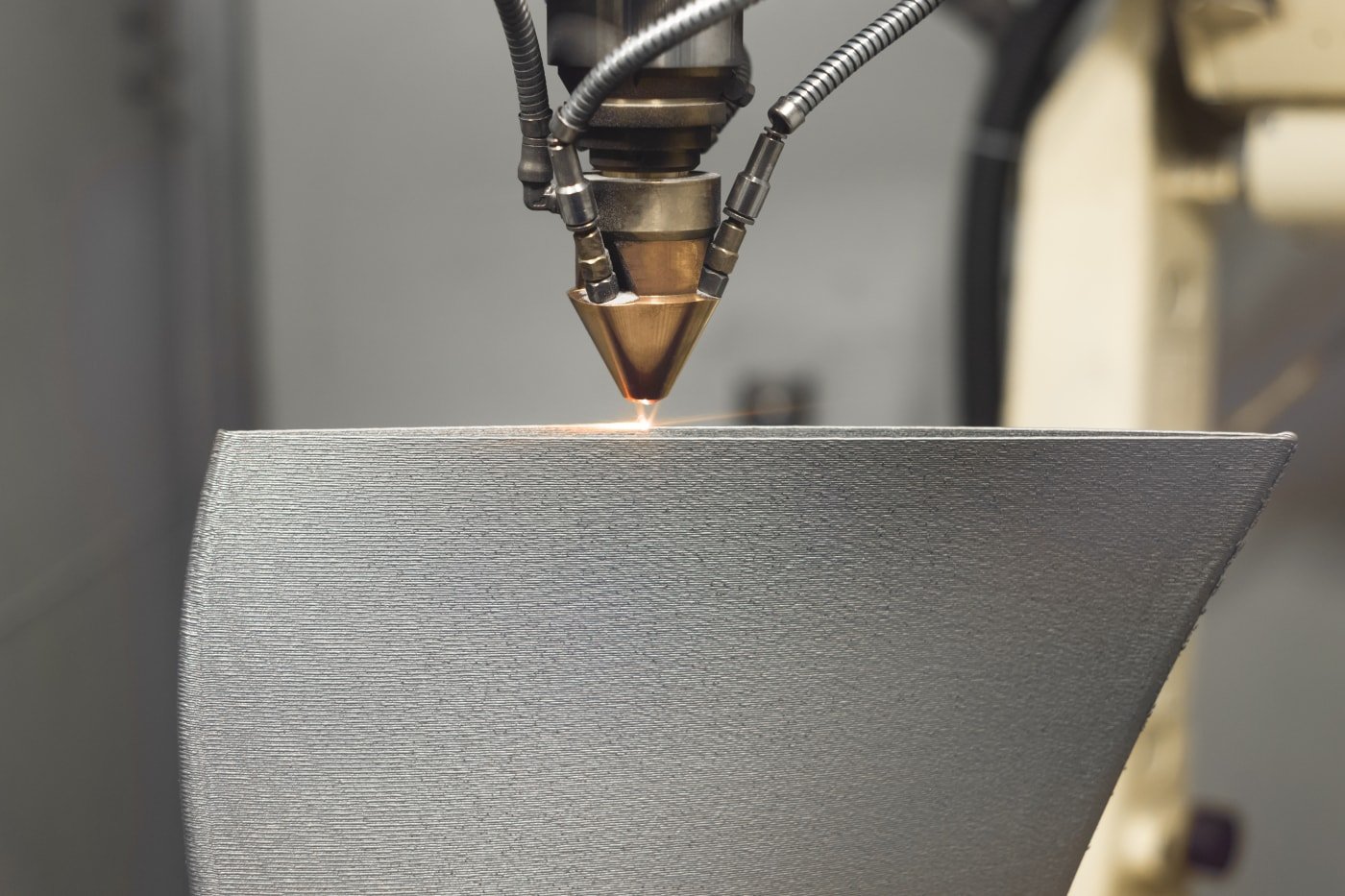

As manufacturing and design techniques get progressively “smarter” with CAM/CAD programs offering generative design and artificial intelligence, these hybrid machines could become a new standard in high-end machine shops working in advanced manufacturing industries like aerospace, medical, defense, and the mold, tool & die market.

Steel cobaltuses

If your shop is focused completely on subtractive manufacturing methods, you are probably thinking that there is no need for an additive option in your shop. Can’t a CNC machine create everything a 3D printer can, and in less time? Not necessarily. Again, by using the two methods together and taking a hybrid approach, you may be able to lower your manufacturing and material costs.

Cobalt steelproperties

Before implementing a hybrid manufacturing approach, it is important to understand the pros and cons of each method. Here is a quick breakdown of both additive and subtractive manufacturing, and the benefits and drawbacks of each.

M42steelcomposition

With recent advancements in 3D printing capabilities, it is becoming easier for manufacturers to use additive manufacturing to create parts from a wide variety of materials, including polymers like ABS, TPE, and PLA as well as carbon fiber composites, nylon, and polycarbonates. Even pricey metals like Titanium, Stainless Steel, and Inconel are becoming increasingly common in the world of additive manufacturing as well.

Looking at the chart above, you will notice that one of the key differences between additive manufacturing and subtractive manufacturing is the surface finish and tolerances that can be achieved with each method. This is where a hybrid approach to additive manufacturing can be extremely beneficial.

For example, you could machine the bulk of a part with typical subtractive machines, which would likely take a very long time using additive methods. Then you can go back to that part with a 3D printer to add intricate features to the part that may take complex programming and hours of planning on a subtractive machine. An impeller is a great example, where the bulk of that part can be machined, but the tricky fins and blades could be printed onto the part, and then finished back on the CNC machine.

There is no doubt that the additive manufacturing space will continue to develop and grow in the coming years, but will it render subtractive manufacturing methods like CNC Machining obsolete? Absolutely not. In fact, precision CNC machining is likely more important to the additive manufacturing process than you may think, as a new process called “hybrid manufacturing” is quickly taking hold in the industry.

As parts come off the printer, they can be quickly moved into a CNC machine with a program designed for part completion. The CNC machine will be able to get 3D printed parts down to the tight tolerances required by many industries and reach the desired surface finish. Advanced finishing tools and long reach, tapered tools from brands like Harvey Tool can easily machine the tight geometries of 3D printed parts, while extremely sharp diamond-coated tooling and material-specific tools designed for plastics and composites can work to create a beautiful, in-tolerance finished part regardless of the material.

The ability of additive machines to literally “add-on” to a part can also make for a cheaper approach to part design. Instead of using expensive materials like Inconel or Titanium to machine an entire part, portions of the part that do not require extreme heat resistance could be machined out of cheaper steel, while the heat resistant portions using expensive materials can be added later through additive methods.

Cobalt steelhardness

MP35N® Nickel Cobalt Alloy is a Multiphase® cobalt nickel-based superalloy, consisting of 35% Nickel and 35% Cobalt. MP35N Nickel Cobalt Alloy is produced using a 2-step melting process, the first step is a vacuum induction melted (VIM), this is then followed by vacuum arc remelted (VAR). This 2-step melt process ensures superior cleanliness and minimizes non-metallic inclusions and residual elements (such as carbon), that have deleterious effects on mechanicals and corrosion resistance. MP35N Nickel Cobalt Alloy can be aged to increase mechanical properties beyond those of stainless and nickel alloys, without sacrificing corrosion resistance. MP35N Nickel Cobalt Alloy can be supplied per AMS 5844 (Sol Treated and Cold Worked), and can then be age hardened to increase mechanical properties.

MP35N® NACE Nickel Cobalt Alloy is a Multiphase® cobalt nickel-based superalloy, consisting of 35% Nickel and 35% Cobalt. MP35N NACE Nickel Cobalt Alloy is produced using a 2-step melting process, the first step is a vacuum induction melted (VIM), this is then followed by vacuum arc remelted (VAR). This 2-step melt process ensures superior cleanliness and minimizes non-metallic inclusions and residual elements (such as carbon), that have deleterious effects on mechanicals and corrosion resistance. MP35N NACE Nickel Cobalt Alloy is produced specifically for use in sour gas (H₂S) service. It is produced by aging, to restrict hardness and limit the susceptibility to cracking in these environments.

Due to the high chromium content (25% – 30% for the grades listed below) cobalt-based alloys provide superior corrosion resistance at high temperatures. The materials are more weldable than nickel-based alternatives. While not as strong as nickel alloys at lower temperatures, above about 1700°F / 930°C cobalt alloys show higher strength. Nickel melts at 2651°F / 1455°C while cobalt melts at 2723°F / 1495°C.

Cobalt steelcomposition

There is also data to demonstrate that casting processes which solidify directionally (centrifugal, for example) lead to improvements in rupture strength and thermal fatigue resistance.

Cobalt steelknife

By designing a workflow like this in your shop, you can spend less time worrying about the precision of printed parts by adding in subtractive operations to keep material costs low, create less waste, and keep parts in tight tolerances for precision machining excellence.

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

Steel cobaltvssteel

Excellent write-up! Kudos to you guys! Your point is absolutely right that 3D printing of metal parts is becoming more common, but subtractive manufacturing is an important part of manufacturing precision additive parts.

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

As hybrid manufacturing workflows become more popular, so do new hybrid manufacturing machines. These hybrid machines are all-in-one machines where both additive and subtractive manufacturing can be performed in a single setup. Many of these machines offer metal 3D printing as well as multi-axis machining capabilities, ready for even the most complex parts thrown their way. With a bit of customization, large-scale 3D printing machines or CNC mills can be retrofit to allow for hybrid manufacturing with add-ons from companies like Hybrid Manufacuring Technologies.

Cobalt based metals are alloyed with chrome, nickel, and tungsten. Due to the high cost of these alloys, they are used where severe conditions prevail and require high temperature strength and hardness, excellent wear, galling, corrosion, and/or erosion resistance.

Overall, in 2021 we are still early on in this new revolution of hybrid machining and advanced design methods, but it is important to understand the role that adding a CNC machine could have in your additive-focused shop, and vice versa. By combining additive and subtractive together, shops can mitigate the cons of each method and take full advantage of the benefits of having both options available on the shop floor.

Specialty Steel Supply makes all reasonable efforts to ensure the accuracy and correctness of the data found on this website and the associated documents but makes no representations or warranties as to the data’s accuracy, correctness or reliability. All data are for general information only and not for providing design advice. It is the responsibility of the user to test specific alloys under actual service conditions to determine their suitability for a particular purpose.

0086-813-8127573

0086-813-8127573