PARKER O-RING #2-258, 6" X 6.25" 101512 - parker -906 oring

The simplest form of tolerance analysis is the single direction, 1D Tolerance Stackup. A 1D Tolerance Stackup is created by creating a cross section of a model and adding the tolerance values for each feature in a straight line.The variation in each contributes to the overall output/outcome.

Every year Dental Products Report surveys our audience to see what technologies are making the biggest impact on the way dental practices operate and the care they provide to patients.

What materials you use for restorative work affects your results. We explore the pros and cons of the types of materials available and the indications of today's chairside CAD/CAM materials.

Tolerancestack-up loop diagram

When you combine the probabilities for each dimension (each separate curve) you get the probability for the total and therefore the distribution curve of the total. Statistical analysis answers the question, given the distribution of variation on each dimension what is the probability that my performance characteristic will fall within defined acceptable limits. The limitation of RSS is that it assumes all inputs are normally distributed and all performance characteristics have a linear relationship with the dimension. These assumptions do not account for the breadth of conditions that exist in typical scenarios found in manufacturing.

The choice in tolerance analysis method is based on many factors, but the can be summarized as “Which method best matches the manufacturing and inspection process of the assembly”. For simple fit problems, a 1D stack-up may be sufficient. RSS is sufficient for the small number of scenarios where the inputs are normal and the assembly relationships are linear. For all other scenarios, Second Order Tolerance Analysis is required to address the real world of manufacturing.

Many companies utilize a statistical method for tolerance analysis. One approach involves a simple calculation using the RSS

Tolerance stackup analysis Excel

Tolerance Stack-Ups are vital to address mechanical fit and mechanical performance requirements. Mechanical fit is simply answering the question, “Do the parts that make up the assembly always go together?” Mechanical performance requirements would include the performance of mechanisms, like switches, latches, actuators, and the like. Other performance requirements could include optical alignments or motor efficiency. So what is a “stack-up”?

Product Bites makes sure you don't miss the next innovation for your practice. This week's Product Bites podcast features new launches from Adravision, Formlabs, Owandy Radiology, Henry Schein Orthodontics, Dental Creations, and Dental Blue Box. [5 Minutes]

Tolerance stackcalculation

In a Worst-Case Analysis, each dimension will have a minimum and maximum value that represents the range of acceptability for that dimension. Worst-Case answers the question, if I take the maximum range on each input, what is the maximum range for the measurement of interest or stackup? We are therefore dealing with the limits of acceptability and not probability.

Add the negative vectors, the arrows pointing to the left, and positive vectors, the arrows pointing to the right, find the difference between the sums of the positive and negative vectors, and subtract the sum of the ± tolerances.

How to dotolerance stackup analysis

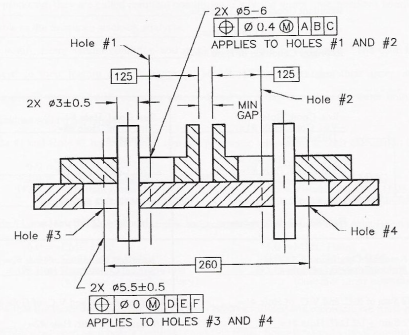

Features with a geometric tolerance are converted to ± tolerances by adding and subtracting the resultant and virtual conditions and dividing the sum and difference by two. Hole numbers 1 & 2 Draw the Loop Analysis Diagram

Open to all U.S. commercial dental laboratories and their employees, the Strategy Milling sweepstakes runs from July 1, 2014 through September 30, 2014. Entering the sweepstakes is easy. Strategy Milling Facebook fans can simply visit the Strategy Milling page at www.facebook.com/StrategyGoldMilling and click on the “Enter to Win” tab. An online registration entry form will appear and dental professionals will be prompted to complete the form as instructed.

Grand Prize winners will be selected and notified within five days of the drawings. A roster of winning names will be available after September 30, 2014 by mailing a self-addressed, stamped envelope to: Atlantic Precious Metal Refining, 920 Riverside Place, Leetsdale, PA 15056.

Method, Root-Sum-Squared. Instead of summing tolerances, as in worst-case analysis, statistical analysis sums dimension distributions. It is important to understand that the inputs values for a worst-case analysis are design tolerances, but the inputs for a statistical analysis are process distribution moments (e.g., standard deviation). Worst-case analysis (also called tolerance stack-up analysis) can be used to validate a design. Statistical analysis (also called variation analysis) can be used to predict the actual variation of an assembly based on the variation of the part dimensions. Comparing the assembly standard deviation to the assembly limits allow for the calculation of quality metrics like sigma, % yield, DPMU, etc. This approach requires distributions to be normal with all parts at the same quality level, i.e. +/- 3σ.

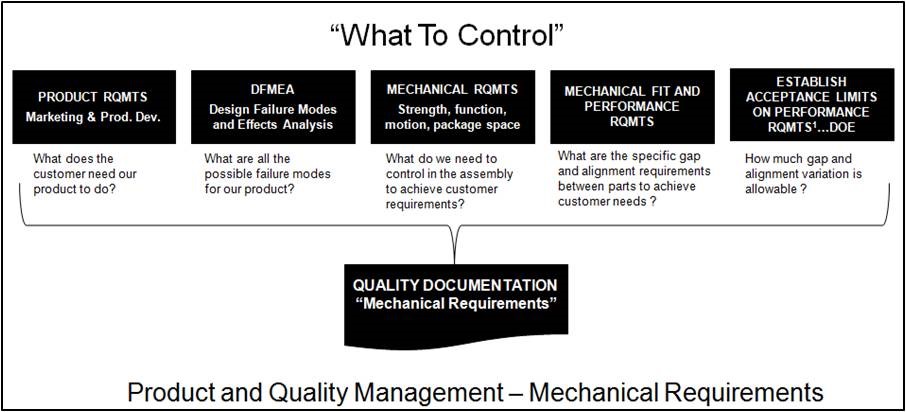

This process for mechanical requirements is generalized in the flow diagram below. to see if the design will work properly. This simple comparison is also referred to as worst case analysis. Worst case analysis is appropriate for certain requirements where failure would represent catastrophe for a company. It is also useful and appropriate for problems that involve a low number of parts. Low being defined as three or four parts. Worst case analysis is most often done in a single direction, i.e. a 1D analysis. If the analysis involves part dimensions that are not parallel to the assembly measurement being studied, the stack-up approach must be modified since 2D variation such as angles, or any variation that is not parallel with the 1D direction, does not affect the assembly measurement with a 1-to-1 ratio.

Strategy Milling©, a division of Atlantic Precious Metal Refining, has unveiled a special Facebook sweepstakes. Currently running on the Strategy Milling Facebook page, the Strategy Milling sweepstakes provides all participants a chance to win three FREE 2% Strategy-milled gold crowns.

What materials you use for restorative work affects your results. We explore the pros and cons of the types of materials available and the indications of today's chairside CAD/CAM materials.

Assembly variation analysis provides insight required to identify the key part characteristics, (KPCs) that must be controlled in order to produce a product that meets the expectation of the customer. The product development process should then become focused on defining and validating part manufacturing and assembly processes that are capable of achieving high producibility levels. Goals of Cpk = 1.67 for key features and Cp = 1.33 for non-key features are commonly quoted. Utilizing the insight for variation analysis allows design engineers to allocate tolerance budgets strategically. Critical features will be held to tighter tolerances. Looser tolerance can be applied to less important features. These decisions not only ensure product quality and performance, but also ensure manufacturability at the right price. The impact on the product development process can be huge.

Product Bites makes sure you don't miss the next innovation for your practice. This week's Product Bites podcast features new launches from Adravision, Formlabs, Owandy Radiology, Henry Schein Orthodontics, Dental Creations, and Dental Blue Box. [5 Minutes]

A statistical tolerance analysis is when you take the variation of a set of inputs to calculate the expected variation of an output of interest. In mechanical engineering, a product design is composed of multiple features, each with tolerance values that control the variable aspects of those features. Statistical tolerance analysis is used to understand how these tolerances contribute the various performance characteristics of the design.

Given the limitations of RSS, other methods for calculating assembly variation have been developed. One such method that is incorporated into CETOL 6 Sigma is called the Method of System Moments. This method eliminates the limitations stated above. Analyses of all complexities, i.e. 1D, 2D, and 3D, can be created with no restriction on distribution type or quality level. Companies can now do full Assembly Variation Analysis with tolerance analysis software.

Every year Dental Products Report surveys our audience to see what technologies are making the biggest impact on the way dental practices operate and the care they provide to patients.

Tolerance stackupexamplePDF

For more information about Strategy Milling, please call 724-266-3269 or visit www.strategymilling.com. For more information about Atlantic, please call 800-289-9293 or visit www.apmr.com.

High Tech Takeover: The 2024 Dental Products Report® Technology Census reveals the start of the industry’s true shift to digital solutions

Non-fans of the Strategy Milling Facebook page can also enter for a chance to win. All dental professionals who are not currently fans of the page are invited to visit the Strategy Milling Facebook page and will be eligible to enter the sweepstakes simply by choosing to “Like” the page. Once the page is Liked, the online registration entry form will appear and the dental professional will be prompted to enter their contact information to be entered in the sweepstakes.

Product manufacturers utilize an organized flow of information to translate customer requirements into product requirements.

Toleranceloopexample

Tolerance stack-up calculations represent the cumulative effect of part tolerance with respect to an assembly requirement. The idea of tolerances “stacking up” would refer to adding tolerances to find total part tolerance, then comparing that to the available gap or performance limits in order

The weekly new products podcast from Dental Products Report is back. With a quick look at all of the newest dental product launches, Product Bites makes sure you don't miss the next innovation for your practice. This week's Product Bites podcast features updated software from Medit. [2 Minutes]

The weekly new products podcast from Dental Products Report is back. With a quick look at all of the newest dental product launches, Product Bites makes sure you don't miss the next innovation for your practice. This week's Product Bites podcast features updated software from Medit. [2 Minutes]

A new winner will be drawn each time 20 entries are received, providing entrants a 1 in 20 chance of winning. The drawings will be held five consecutive times. Once 100 total entries are received and winners are drawn, the 95 non-winners will be entered into a second drawing providing an additional 1 in 95 chance of winning. This last drawing will then cease all opportunities within the sweepstakes for these entrants. However, the sweepstakes drawings will continue until the end date of the sweepstakes timeline, and these same rules apply for every 100 submissions received.

Because manufacturing methods vary for different types of parts, the distribution moments or parameters change as well. RSS only uses standard deviation and does not include the higher moments of skewness and kurtosis that better characterize the effects tool wear, form aging and other typical manufacturing scenarios. Second Order Tolerance Analysis incorporates all distribution moments: Second Order Tolerance Analysis is also needed to determine what your output is going to be when the assembly function is not linear. In typical mechanical engineering scenarios kinematic adjustments and other assembly behaviors result in non-linear assembly functions. Second order calculations are much more complex so hand calculations are not advisable but the computation accuracy is greatly improved and becomes viable within a tolerance analysis software package.

RSS (Root-Sum Squared) Statistical Analysis does not focus on the extreme values, but focuses on the distribution of the variation for each dimension. Each dimension will have a unique distribution of values based on the manufacturing process. Tool wear, operator differences, changes in material and environment all contribute to variation in the dimension value. Each dimension has its own distribution curve.

High Tech Takeover: The 2024 Dental Products Report® Technology Census reveals the start of the industry’s true shift to digital solutions

0086-813-8127573

0086-813-8127573