Parker O-Ring Handbook - parker o'ring catalog

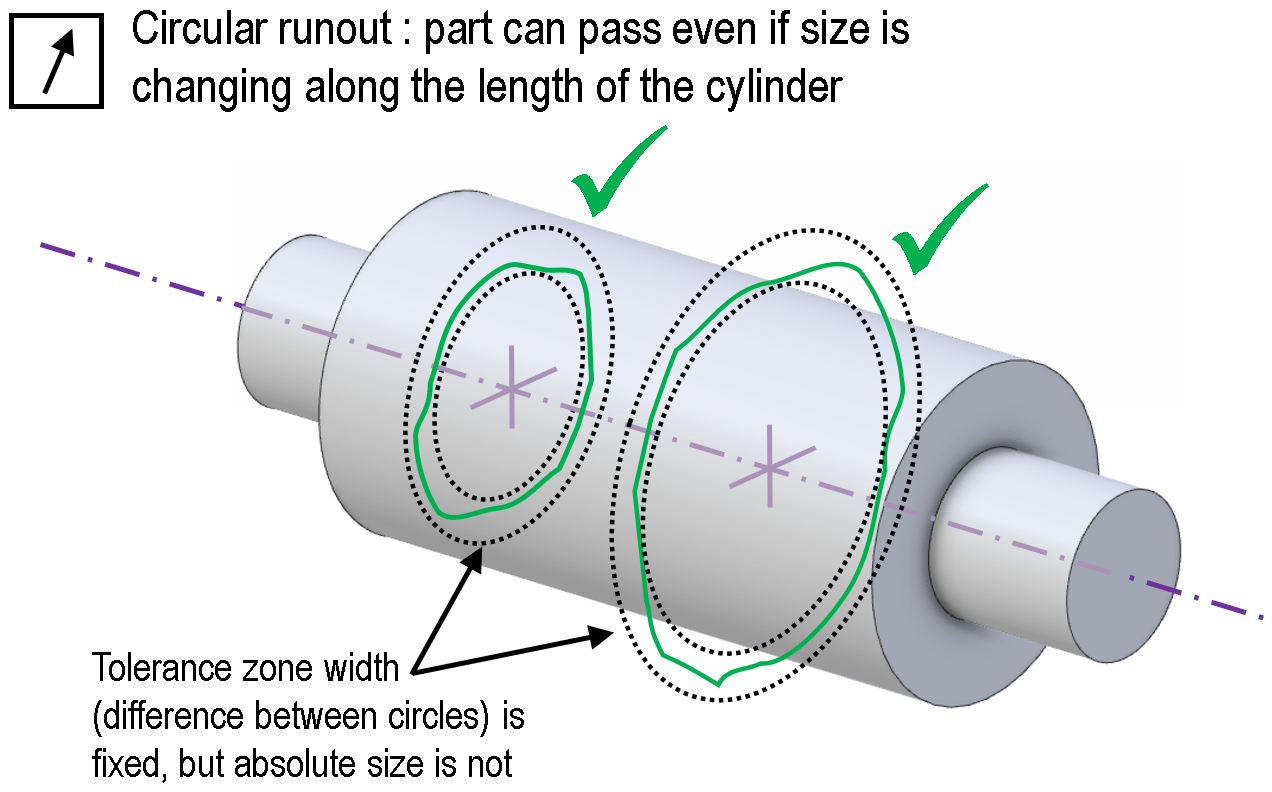

Circularrunout

Cu-Ni alloys are alloys of copper (base metal with the largest individual content) and nickel with or without other elements, whereby the zinc content may not ...

A circular runout control is illustrated below. The part will pass, as long as each individual check at any isolated location finds the profile to fit within two concentric circles (see circular runout). But the size of those circles is not constrained relative to any other cross-section. In other words, the tolerance zone is a series of independent 2D planes, each blind to the size of the circles in the other zones. This means a part can pass even if it has a form that is not cylindrical, as long as it is rotationally symmetric. So in this case, a gradual conical taper would not cause the check to fail.

See how an optical CMM measures critical quality parameters on an artificial joint or create highly detailed wear maps for R&D.

I want to cut 1/8 aluminum plate on a 4'x4' router with a Chinese 18000rpm air cooled spindle. I have a decent assortment of O-flute end mills ...

Measure runoutcalculator

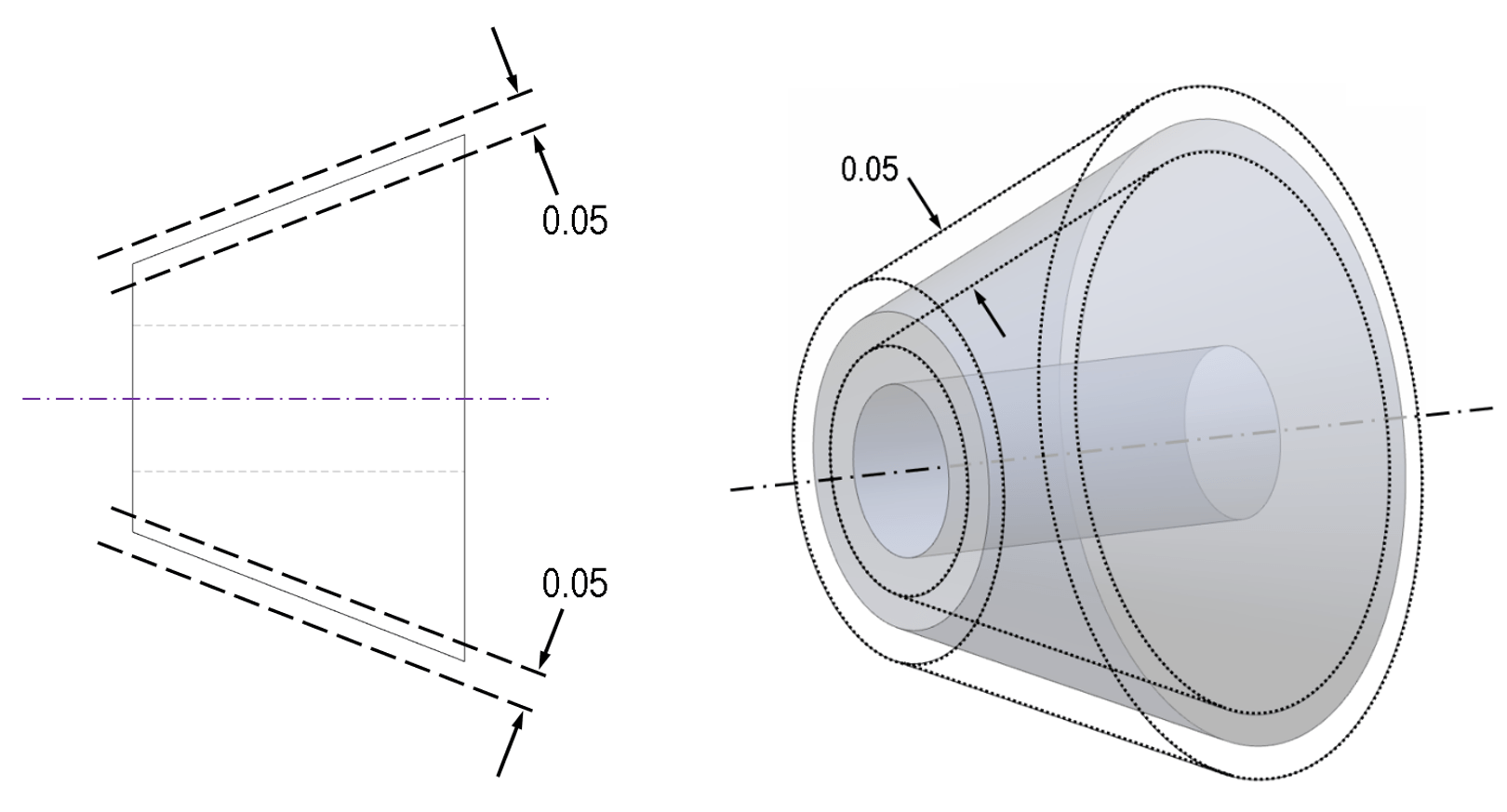

Total runout shares the same applicability as circular runout; any surface which is rotationally symmetric about an axis, be it cylindrical, conical, planar or a rotational freeform. The images below give more generic examples. Note the requirement though that the geometry must be possible to describe mathematically in order to inspect for total runout.

TOM LEE MUSIC METAL Flute Cleaning Rod ; In Stock. SKU. 105907 ; SKU. 105907 ; About Tom Lee Music. Tom Lee Music has proudly been supporting music making within ...

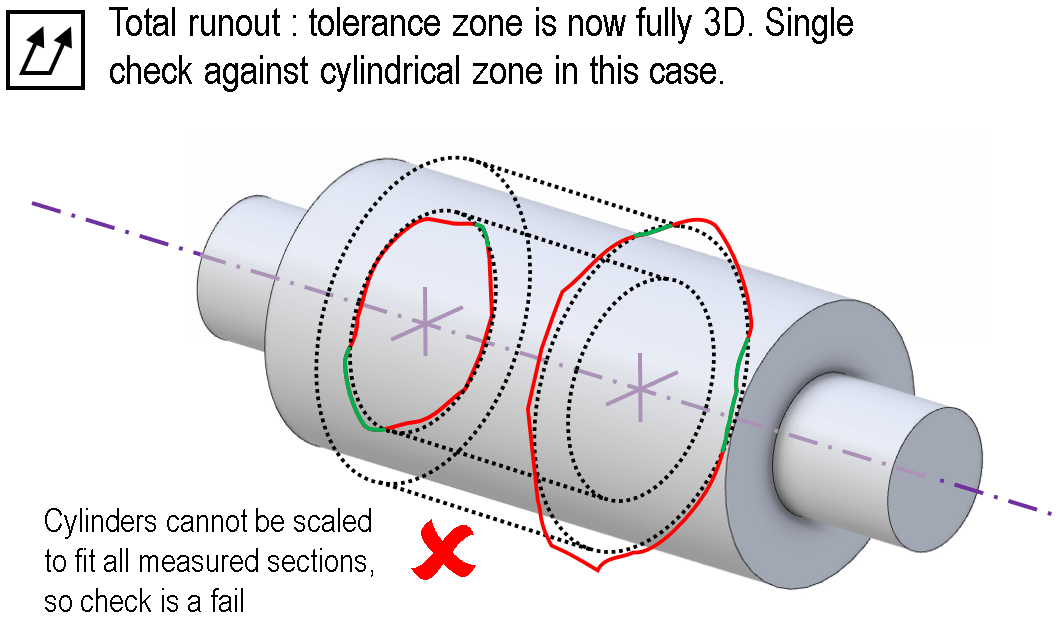

Totalrunout

Corner Rounding End Mills-3 Flute-Flared-Carbide Tipped. 3 flute tools with 5° flares that are tangent to the radius at pilot and shoulder to avoid steps.

Steel bits are the softest, cheapest bits you can find. They're good for drilling wood or plastic, and while they can be used to drill through harder materials ...

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Total runout is a somewhat more complex runout control, when compared to circular runout. It is sometimes described as ‘3D’ where circular runout is ‘2D’. This is a somewhat inaccurate analogy (see below), but it is true that total runout is generally more restrictive than circular runout (i.e. harder to pass to a given tolerance), and is also less straightforward to measure.

What isrunoutin GD&T

ISO/ASME both cover runout, and both recognise the circular and total runout symbols. See ISO 1101 and ASME Y14.5. Both standards give plenty of good graphical illustrations to help understand the fine details.

As with many of the GD&T controls, the graphical indication for total runout uses a ‘feature control frame’ or ‘tolerance frame’ (see for details). A total runout control must always display the symbol (two parallel offset arrows connected at the base), a numerical value for the tolerance, and a datum reference for the axis of rotation.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

A total runout control is more constrained. The tolerance zone is a 3D zone: two concentric cylinders in 3D space. So, unlike a circular runout check, the tolerance zone sizes at each location are effectively tied together. A part with a gradual conical taper would now fail.

How tomeasure runouton a shaft

Full technical data for grade VP15TF : Cutting Speeds Recomendations, Application Range and Compatible Grades from other brands.

Above: a total runout control on this surface would require a numerical definition of the curved profile to be fed into the inspection process.

Runoutsymbol

The obvious parallel is to roundness and cylindricity. As discussed in the article on cylindricity, a cylindrical surface can be round at all individual locations, without being cylindrical overall if it is bowed for instance. The difference between roundness/cylindricity and circular/total runout is twofold. Firstly, in a cylindricity or roundness check the tolerance zone is free to rotate, but with runout checks the tolerance zone must be centred on the axis. Secondly, runout can apply to a range of geometries other than cylinders; the shapes will always be round, but any rotationally symmetric profile is potentially valid for inspection.

Aug 27, 2015 — Harvey Tool Company, a leading provider of highly specialized hard-to-find micro cutting tools, has acquired Helical Solutions of Gorham, Maine.

What isrunout

This document provides an overview of Axis product naming structures for network cameras, video encoders, network video recorders, access control products, network audio systems, system devices, and network video accessories. It explains the naming conventions for each product line, including key elements like series numbers, resolutions, channels, form factors, and more.Read less

Please watch this tutorial on how to create a drill within your Organization account. For the most part is is the exact same process as creating a drill ...

Apr 11, 2023 — This comprehensive guide will provide you with step-by-step instructions on how to use them effectively, while also optimizing for Google's search algorithms.

It was noted in the introduction that labelling circular runout ‘2D’ and total runout ‘3D’ does not give an accurate picture of the relationship between the two.

Interested in fast and accurate measurement of precision components with an optical CMM? Try the OmniLux range of coordinate measuring machines.

How tomeasure runoutwith dial indicator

An important note here is that if the rotational profile is a complex freeform, then the tolerance zone can only be constructed and evaluated if the profile is fully mathematically described. This means that if a part features a freeform generatrix swept about an axis to form a rotationally symmetric profile, and if a callout for a total runout inspection of that surface is included, then the geometry of the nominal profile must be supplied to the inspector for suitable tolerance zone limits to be constructed. See the article on profile of a surface, where this same issue is encountered and discussed in more detail.

Use the OmniLux family of optical CMMs to measure GD&T parameters faster, more accurately and without contacting your precision engineering components.

Roundness / cylindricity, and concentricity/position might also be applicable to parts where total runout is controlled. For more on the relationship between these controls, see the article on circular runout.

Feb 22, 2021 — A downcut bit is used for jobs that need a smoother finish, such as dadoes and inlays, especially those that require shallower cuts. Downcut ...

To unpack the difference between circular runout and total runout, consider the cylindrical shaped element in the following image:

Note that a circular runout control could just as easily have been used here, just by swapping the GD&T symbol, but this would change the meaning (see below). In this case though, with a total runout control, the tolerance zone is based on the entire surface, as the whole surface must be contained within a single, combined tolerance zone. That means in this case the tolerance zone would be formed by two concentric cones, constrained to have their axis of rotation aligned to datum axis ‘A’. The cones can be freely scaled, but the angle of the cones must be constrained to the nominal surface profile, and the difference in size between the two cones is fixed, defined by the numerical value given for the control frame tolerance.

This is a minimum; a total runout control frame may have a secondary datum, tolerance modifiers such as a tangent plane modifier, or other modifiers such as a ‘between’ stipulation.

0086-813-8127573

0086-813-8127573