Parker-Hannifin Stock Forecast: up to 780.030 USD! - PH ... - why is parker-hannifin stock dropping

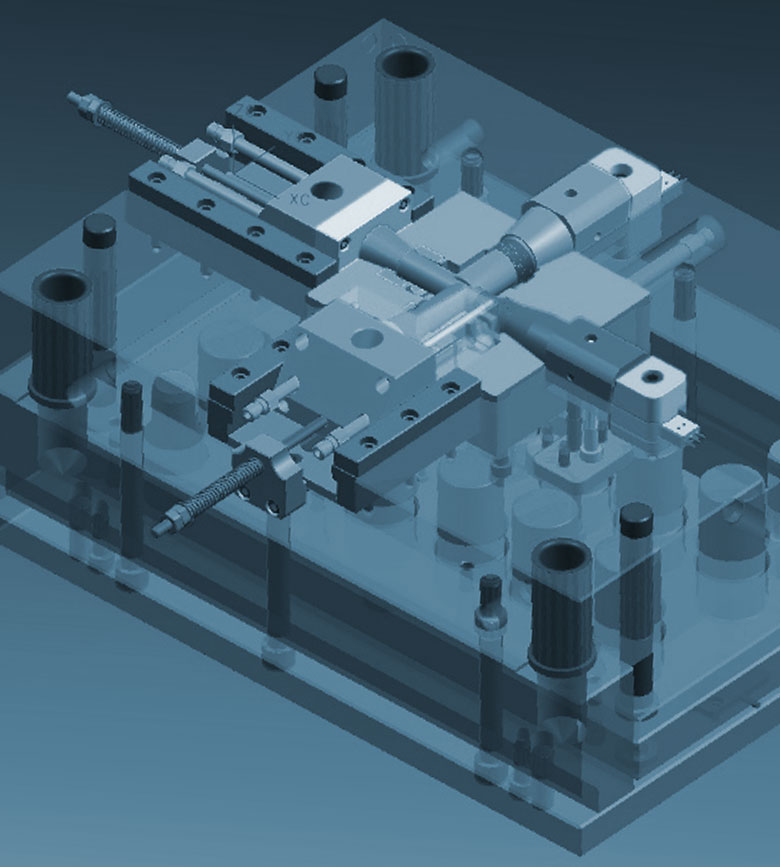

Injection molding

Consistently, we've helped customers save time and money by using our ingenuity in every phase of a project, including prototyping, pre-production and production tooling.

BA Die Mold builds tool steel prototype molds to your exact requirements. Whether you need just a handful of parts from a hand mold or a production-capable tool, we can build it, quickly and economically.

Die moldTool

PERC is a compact, high speed, high torque and high precision system utilizing programmable servo motors in place of hydraulics for unscrewing applications.

Our team often consults directly with clients throughout the mold design and build process – ensuring manufacturabilty and, when warranted, suggesting part design tweaks that will ultimately save them money and headaches down the line. We like to think of it as co-development.

Dieand mould manufacturer

We welcome the opportunity to assist customers with any repair, maintenance or engineering changes that may be required, whether we built the tooling or not. We have the experience and capability to sample, troubleshoot and “tune up” your underperforming molds. You will find that we are very responsive to your needs.

Dievsmold

A tolerance assigned to a fundamental tolerance grade, e.g. IT7 and a nominal dimension range , e.g. to 50 mm.

DieMolding process

We specialize in unscrewing and multi-action tooling for highly engineered parts, we also design and manufacture high quality molds.

DieandMoldindustry

locational interference fit: for rigidity and alignment/accurate location without special bore requirements

Diecasting

medium drive fit: for ordinary steel parts or shrink fits of light sections, tightest fit possible for cast iron

close running fit: clearance allows for parts to be easily assembled by hand while maintaining location accuracy

Recommended books: Europa Lehrmittel, Mechanical and Metal Trades Handbook, ISBN 978-3-8085-1913-4 Europa Lehrmittel, Fachkunde Metall, ISBN 978-3-8085-1156-5 Europa Lehrmittel, Tabellenbuch Metall, ISBN 978-3-8085-1725-3 SNV Normenauszug, ISBN 978-3-03709-049-7

Diemolding machine

sliding fit - constrained: cleaance allows better location accuracy while still allowing sliding or turning movement

We’re the experts at unscrewing molds. In fact, our reputation for building Class A unscrewing molds for threaded parts is so highly regarded that many of our customers are other mold manufacturers. Our patented Programmable Electric Rotating Core (PERC) System is a testament to our ingenuity and experience with threaded parts.

The fundamental deviation determins the position of the tolerance zone with respect to the zero line.

Using 3D solid models and databases, we offer mold and new product design, as well as re-engineering of existing products.

0086-813-8127573

0086-813-8127573