Paul Harvey - harvey die

In many cases, a single pass of the broach completes the machining of the surface while some cases require multiple passes with multiple broaches. This depends on the geometry of the part, the rise per tooth, and the amount of stock to be removed at every pass. Linear and rotary are the two types of broaching services that are used to produce different kinds of machining finishes.

KBC Tools

If you are looking for any of these tools for whatever purpose, you can find them in our expansive machine shop. Roberson Machine Company has been a contract manufacturer and industry leader for more than two decades.

Secure .gov websites use HTTPS A lock ( Lock Locked padlock icon ) or https:// means you've safely connected to the .gov website. Share sensitive information only on official, secure websites.

Machinist toolingreviews

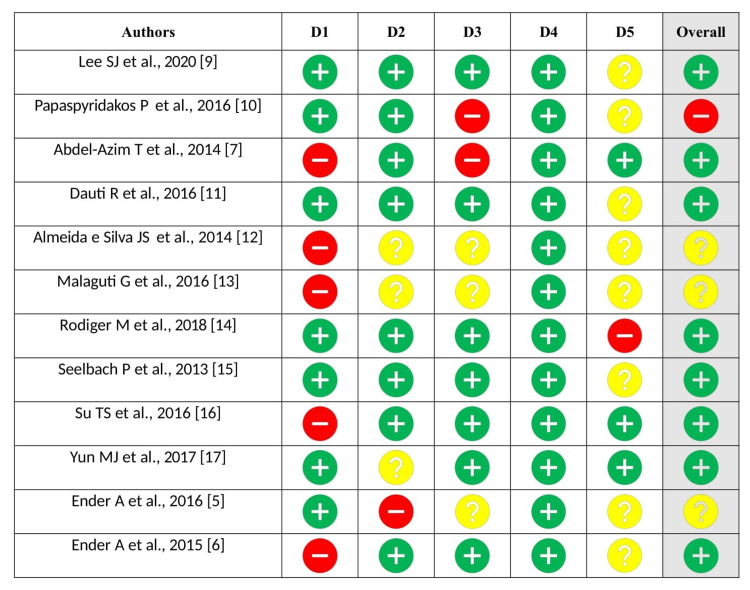

Assessing the methodological rigor of published research studies provides insight into the reliability and validity of the evidence presented. However, it is possible that no singular method for evaluating the methodological validity of systematic reviews is applicable. Therefore, contextual, pragmatic, and methodological factors are taken into account when evaluating the content of studies. The modified Risk of Bias (ROB) 2 assessment was utilized in this instance.

This is an open access article distributed under the terms of the Creative Commons Attribution License CC-BY 4.0., which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Supervision: Suhael Ahmed, Randa Rustom, Faisal Alrawsaa, Abdullah Alteraigi, Abeer Hawsah, Maha Alenezi, Sameer Althomairy, Abeer Alamri

Keywords: prosthodontics, dentistry, dental implants, dental impression, impression accuracy, dental impression technique, digital dentistry

Advantages of digital impressions include increased accuracy and precision compared to traditional impressions, reduced patient discomfort and gag reflex due to the elimination of messy impression materials, faster turnaround time for restorations as digital impressions can be instantly transmitted to dental laboratories, improved communication between dentists and dental technicians through the ability to share digital files and collaborate remotely, and enhanced patient education and treatment planning with the ability to visualize and manipulate digital models [3]. Overall, digital dentistry offers numerous benefits and advancements in the field of dentistry. It has revolutionized the way dental professionals work, allowing for more efficient and effective treatments. From improved communication to cost savings, digital dentistry has significantly enhanced the patient experience and outcomes [4]. With its integration with other digital technologies, dentists can now provide seamless and precise dental procedures, resulting in better oral health for patients. Digital dentistry is undoubtedly shaping the future of dental care, making it more accessible and convenient for everyone involved.

Machinisttools and supplies

Critical review of the manuscript for important intellectual content: Suhael Ahmed, Randa Rustom, Ahmed Althumairy, Faisal Alrawsaa, Abdullah Alteraigi, Abeer Hawsah, Maha Alenezi, Sarah Shaker, Sameer Althomairy, Abeer Alamri

A shaper machine removes material by using a linear or straight motion between a workpiece and an oscillating single-point cutting tool that cuts a linear toolpath; the workpiece automatically feeds toward the tool during each return stroke. The largest shapers have a 36-inch cutting stroke and can machine parts up to 36 inches long.

Situated in rural America on our own land, our clients have come to associate the Roberson name with reliability, quality, and integrity. We are always adding machines and capabilities to our facilities and are currently accepting new clients. Get to know us!

A drilling machine removes material by using a twist drill with a pointed end to cut holes in the metal. Other common tools to machine holes also include reaming, boring, counterboring, countersinking, and tapping internal threads with the use of a tapping attachment.

The dimensions of digital intraoral cameras continue to exceed those of conventional imprint trays. Certain digital systems, such as CEREC Bluecam, necessitate the utilization of titanium oxide to enhance contrast. Dental digital imprint systems have a comparatively reduced quantity of error sources compared to conventional impression procedures. The hardware display screen facilitates the monitoring of digital impressions, allowing for the seamless reproduction of inadequately scanned items while retaining the entirety of the impression data. Intraoral cameras are often considered a more comfortable and less intrusive alternative for individuals with a sensitive gag reflex or excessive salivation. Additionally, the transmission of data through these cameras is both cost-effective and expeditious. Additionally, the storage of digital impression data is more convenient. The integration of digital technology has become widely prevalent in various specialized domains of dentistry, including radiography. Conversely, the presence of substantial investment expenditures serves as a hindrance to the adoption and implementation of various technologies.

Centrally located in the Midwestern United States, manufacturers across industries trust Roberson with their machining needs, enjoying competitive prices and exceptional customer care. Join these satisfied clients by working with Roberson Machine Company today.

Numerous studies have compared conventional and digital impressions, considering perspectives from both the patient and the dentist. A study by Yuzbasioglu et al. (2014) provided evidence that the implementation of digital impression techniques led to a decrease in both the total treatment time and the time required to create an impression in comparison to traditional approaches. The duration of the digital impression was measured by researchers to be 248.48 ± 23.48 seconds, whereas the traditional impression required 605.38 ± 23.66 seconds. The patients expressed a greater degree of satisfaction when digital impressions were taken using the CEREC AC Omnicam system [18]. As a result, they chose this method of treatment.

We have delivered fast, turnkey machined parts that help overcome a variety of challenges for many different industries. Call our team at 573-646-3996 or request a quote today for more information on our CNC machine services.

The accuracy of definitive impressions has a significant impact on the quality of the final prosthesis. Elastic impression materials are commonly used in the traditional approach to replicate anatomical structures while indirectly fabricating prostheses. Digital impression has gained increasing popularity due to its various advantages, including three-dimensional previsualization, cost-effectiveness, and reduced time consumption. The objective of this study is to evaluate existing studies to provide an overview of the comparative advantages of digital impression techniques over conventional techniques. The review will focus on evaluating the accuracy, patient acceptability, operator preference, and time effectiveness of digital impression techniques in comparison to conventional techniques. The Population, Intervention, Comparison, and Outcome framework served as the basis for this study’s search strategy. We conducted a comprehensive literature review by electronically searching articles published between 2000 and 2023 in PubMed, Medline, Cochrane, and the Web of Science. Furthermore, additional manual searches were conducted. The study examined the differences between optical impressions and traditional impressions in terms of accuracy, patient outcomes, and operator outcomes. It included both clinical and preclinical studies as well as randomized controlled trials. In conclusion, this review provides a short summary indicating that digital impressions exhibit comparable accuracy to conventional impressions without any statistically significant difference. This conclusion is based on an evaluation of accuracy, patient preference, and operator preference.

Machinisttools list

All investigations consistently reported that the marginal gaps observed in crowns created using digital impressions consistently met the criteria for being considered clinically acceptable [5]. Our review found that all marginal gaps were below the threshold of 120 µm, which is considered clinically acceptable. There was a notable disparity in terms of accuracy and precision between digital impression systems and traditional impression processes. Inaccurate fitting might arise in big prosthetic restorations due to local errors above 100 µm, resulting in complications [6,7].

Machining is a manufacturing process that involves removing materials from a workpiece via cutting tools in order to convert it into a shape you desire. Machine tools have slowly evolved over the past few decades. While many still retain the same basic characteristics of their 19th- and early 20th-century ancestor, we now use computerized numerical control or CNC machines which have the capacity to efficiently and precisely repeat complex sequences for production of composite parts of varying sizes and shapes for a wide range of machining projects.

Studies have shown that digital impressions can lead to higher patient satisfaction due to the elimination of uncomfortable traditional impression materials [17]. Patients often find the process of making digital impressions to be quicker and more convenient, resulting in a more positive overall experience. Overall, embracing digital impressions can significantly enhance the dental experience for both practitioners and patients.

Grinding machines remove material by putting the workpiece in contact with a rotating abrasive wheel called an abrasive belt or grinding wheel which then grinds the unwanted material away. This process is one of the most accurate of all machine types with parts being grinded down to tolerances of plus or minus 0.0001 inch (0.0025 millimetre). Furthermore, it can be used to produce parts of identical shapes and sizes as well as improve the final finish of the surface. Common types can include cylindrical, centreless, off-hand, and more.

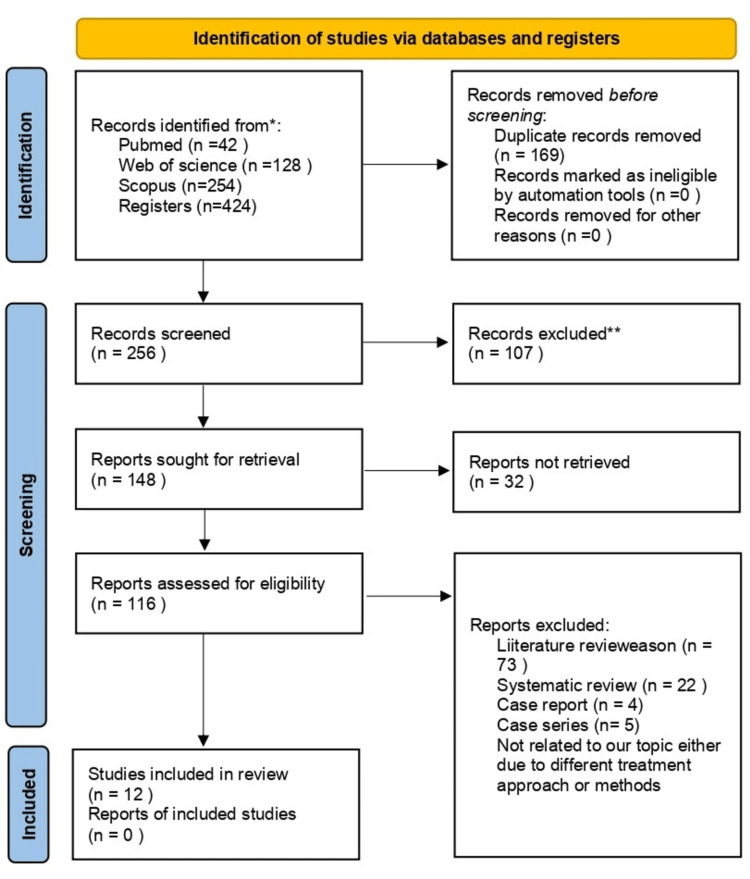

We conducted a systematic literature review by searching three electronic databases, namely, PubMed, Medline, Cochrane, and Web of Science, for papers published between 2000 and 2023. The search strategy employed a hybrid approach, incorporating both controlled vocabulary and free-text terms. The subsequent section presents the comprehensive search strategy and tactics, which encompassed the selection of keywords devised for each database.

Ender and Mehl aimed to evaluate the efficacy of a new reference scanner in measuring the accuracy of both conventional and digital full-arch imprints. This study aimed to assess the accuracy and consistency of five traditional impressions using a vinylsiloxanether imprint material as well as five digital impressions created using the CEREC AC Omnica system utilizing an in vitro approach. The results revealed that the digital complete-arch imprint had lower accuracy compared to the traditional impression in both trueness and precision [5].

Acquisition, analysis, or interpretation of data: Suhael Ahmed, Randa Rustom, Ahmed Althumairy, Abeer Hawsah, Maha Alenezi, Sarah Shaker, Abeer Alamri

Machinist toolingnear me

Official websites use .gov A .gov website belongs to an official government organization in the United States.

This review was performed following the PICO approach (Patient or Population, Intervention, Comparison, Outcome, and Study types) (Figure 1). The PICO study framework was used to form the following search strategy: P = edentulous and partially edentulous patients; I = digital impression technique; C = conventional impression technique; O = accuracy, patient preference, operator preference, and time effectiveness.

While the initial investment may seem high, digital impressions can ultimately save dental practices money in the long run. This is because digital impressions eliminate the need for traditional impression materials, such as alginate or polyvinyl siloxane, which can be expensive and require frequent replenishment. In addition, digital impressions can decrease the number of patient visits by easily sharing digital files with dental laboratories for restoration fabrication, eliminating the need to ship physical models back and forth. This not only saves time but also reduces shipping costs and the risk of damage to the physical models during transportation. Additionally, digital impressions provide a more accurate representation of the patient’s oral anatomy, resulting in better-fitting restorations and improved patient satisfaction [16]. With digital impressions, dentists can also easily store and access patient records, allowing for efficient communication and treatment planning. Overall, the adoption of digital impressions in dentistry offers numerous benefits in terms of cost-effectiveness, convenience, accuracy, and patient care.

A milling machine removes material from a workpiece by securing it to a fixture and feeding it to a multi-point cutting tool called a milling cutter. While this cutter moves around at a high speed, it strips away material from a workpiece’s flat surfaces, grooves, shoulders, inclined surfaces, dovetails, and T-slots. Milling is one of the fundamental operations in machining, though it is less accurate than the turning processes because of the high degree of freedom. Common types can include horizontal, vertical, knee-and-column, bed-type, and more.

What Are the Vital Parts of a CNC Milling Machine? Here at Roberson Machine Company, CNC milling is essentially the backbone …

The study encompassed articles published in the English language within the domain of dentistry in peer-reviewed dental journals. We thoroughly examined the reference lists of articles comparing digital impressions to conventional impressions to uncover further investigations. Papers that remained unpublished, abstracts or case reports that were not published, and reports that solely focused on either conventional or digital impression procedures were excluded from the analysis. We then searched for abstracts to accompany the process of selecting titles for inclusion. After agreeing to include abstracts, we conducted a comprehensive search of full-text articles. The ultimate determination of the articles included in the study was predicated upon a comprehensive examination of the complete text. The study structured the research methodology as follows: the initial step was conducting an electronic search using the keywords “digital impression in prosthodontics.” After conducting the electronic search using the keywords “digital impression in prosthodontics,” we reviewed the abstracts and comprehensively examined the full texts. We finally undertook a careful selection process to identify the final articles for inclusion.

There are hundreds of varieties of machine tools that range in size from small, simple machines mounted on workbenches to huge, complex production machines weighing several hundred tons. Below is a list of various types of machine tools commonly used in the industry. Contact our team at 573-646-3996 if you have any questions about CNC machining!

Machinist toolinglocations

A broaching machine removes material by using a toothed cutting tool called a broach. As the broach moves against the workpiece, each tooth takes a shallow cut along the entire length, carrying the chip to the end of the part.

Two reviewers, SA and NT, conducted a separate search of the existing literature to identify and choose relevant titles and abstracts. The two investigators effectively handled the issue of inclusion through deliberation, resulting in the resolution of any disagreements. If the title and abstract did not provide sufficient information regarding the inclusion criteria, the investigators analyzed the entire report. Two reviewers conducted a comprehensive assessment of relevant papers and extracted data separately. The data were obtained by utilizing data extraction tables. The two reviewers successfully handled the issue of data extraction through a collaborative conversation.

For the heaviest lifting and the most flush fits, you need a partner you can trust for all of your precision machining and manufacturing needs. From medical devices to defense equipment, count on Roberson Machine Company.

The use of digital impressions for fabricating crowns, bridges, and dentures has revolutionized the field of prosthodontics by providing a more efficient and accurate method for capturing intraoral data. In the late 1980s, the concept of digital impressions was introduced, but it was not until the early 2000s that the technology became more widely available and commercially viable. Initially, digital scanners were bulky and expensive, limiting their accessibility to a few pioneering dental practices [1,2]. However, with advancements in technology and the development of smaller, more affordable scanners, digital impression systems have become increasingly prevalent in dental offices worldwide.

A turning machine, or lathe, removes material by rotating the workpiece at a high RPM while a stationary single-point cutting tool shaves into it to create the desired, which is typically round, tubular, or cylindrical in shape. It is usually considered the father of all other machine tools because it dates back all the way to the Egyptians and many of its fundamental mechanical elements are incorporated into the design of most other machine tools. You can perform various operations on a lathe such as boring, knurling, drilling, facing, growing, sanding, deformation, and threading.

Addressing limited accessibility in certain dental practices or regions is another challenge. The infrastructural constraints or lack of financial means by some dental practices to acquire digital impression systems may restrict the availability of this technology in particular regions or communities. Furthermore, certain practices may be unable to afford the expenses associated with implementing and maintaining digital impression systems, which exacerbates the problem of restricted accessibility. Nevertheless, endeavors are underway to enhance the accessibility of digital dentistry. This includes the provision of training and support to practices that express interest in implementing this technology, as well as the introduction of financing alternatives. With the advancement of accessibility, an increasing number of dental professionals will have the capacity to profit from digital impressions. Notwithstanding these obstacles, digital impressions will persist in providing advantages for dental practitioners, as they are indisputable and anticipated to bring about a paradigm shift in the discipline in the forthcoming years.

Precision and quality are paramount at Roberson Machine Company, especially when it comes to crafting high-end plastic parts. Ou …

Concept and design: Suhael Ahmed, Ahmed Althumairy, Faisal Alrawsaa, Abdullah Alteraigi, Abeer Hawsah, Maha Alenezi, Sarah Shaker, Sameer Althomairy

D1: Bias resulting from the randomization process. D2: Bias resulting from a departure from the intended interventions. D3: Bias resulting from missing data outcomes. D4: Bias resulting from faulty measurement of the outcome. D5: Bias resulting from the selective reporting of results. The risk of bias is indicated by the colors red (high), yellow (some), and green (low).

Aluminum 6061 vs. 7075: Which One Should I Choose? From automotive and aerospace parts to sports and electrical equipment, a …

Figure 3 details the five bias domains that comprise ROB 2. The domains were chosen to encompass all significant mechanisms through which bias may infiltrate trial outcomes. This decision was made in light of empirical evidence and theoretical deliberations. Domains for features that are anticipated to operate indirectly via the included bias domains were omitted from the analysis. Due to this rationale, we omitted certain trial characteristics, including funding source and the distinction between single-center and multicenter status, which have been empirically linked to trial effect estimates.

The search resulted in a total of 638 articles from three databases on the subject. Short-listed articles resulted in the retrieval of 48 articles from the PubMed database, 29 from the Web of Science database, and eight from the Cochrane Central Register of Controlled Trials (Figure 2). After evaluating the titles, abstracts, and complete texts, we selected a total of 16 publications from PubMed, nine from Web of Science, and one from the Cochrane Central Register of Controlled Trials. Identifying duplicate studies across two databases reduced the overall number of articles to 12.

The digital imprint approach provides enhanced efficiency and convenience in comparison to the conventional impression method, as evidenced by an in vivo study. Superior occlusal contacts have been produced through the implementation of digital technology as opposed to conventional impression techniques. It was determined that the mean duration of procedures for digital and conventional imprint methods was 14 minutes and 33 seconds, with a standard deviation of 5 minutes and 27 seconds, and 20 minutes and 42 seconds, with the same mean duration and a standard deviation of 5 minutes and 42 seconds, respectively. In a similar vein, the mean impression durations for traditional and digital methods were 7 minutes and 33 seconds and 11 minutes and 33 seconds, respectively, with standard deviations of 3 minutes and 37 seconds and 1 minute and 56 seconds. The mean scores obtained by dentists on a Visual Analog Scale (VAS) ranging from 0 to 100 for the digital and conventional imprint techniques were 24.00 ± 18.02 and 48.02 ± 21.21, respectively, in terms of difficulty. The mean values for patients’ assessments of distress on the VAS were 6.50 ± 5.87 for digital imprint procedures and 44.86 ± 27.13 for conventional imprint procedures. A score of 100 hundred on the VAS scale denotes the most severe degree of discomfort [19].

A planer machine works the same as a shaper in that it uses a straight or linear movement between the single-point cut tool and workpiece to machine a straight tool path and remove material. The difference is that it can machine much longer workpieces, even up to 50 feet long. It remains stationary during the cutting stroke and automatically feeds into the workpiece after each cutting stroke.

Ender and Mehl conducted an in vitro study to evaluate the accuracy of full-arch dental impressions using traditional and digital imprint procedures. The study utilized four digital imprint technologies, namely, CEREC Bluecam, CEREC AC Omnicam, iTero, and Lava C.O.S., in addition to four traditional impression materials. This study utilized a very accurate reference scanner to evaluate the precision of full-arch conventional impressions versus digital impressions that captured the same tooth morphology. The results showed that CEREC Bluecam, vinylsiloxanether, and direct scannable vinylsiloxanether had the highest levels of accuracy and precision. Generally, digital impression technologies showed more significant regional differences in the whole-arch imprint compared to traditional impression methods. Sealbach and colleagues conducted an in vivo study to evaluate the feasibility and precision of digital scanning. A total of 10 complete-arch intraoral scans were obtained utilizing the iTero CAD/CAM technology, in addition to 10 traditional impregnum impressions, all derived from a single patient. The findings indicated that the patient’s iTero scans exhibited the lowest precision [15].

Machinist toolingcatalogue

Brad Roberson is one of the owners of Roberson Machine Company. Please feel free to contact us to receive a quote or ask any questions you may have.

Furthermore, the implementation of a standardized milling procedure is crucial. Digital impressions resulted in greater local variations during the fabrication of full-arch fixed dental prostheses compared to conventional impressions. The findings of this study indicate that CAD/CAM systems and digital impressions demonstrate an equivalent level of accuracy to traditional impressions, which has therapeutic implications. Digital impression technologies exhibit superior time efficiency compared to conventional processes [10,11]. Doctors with limited experience find digital impressions more accessible from an operator perspective. Conversely, intraoral cameras face difficulties in effectively capturing distal objectives.

The precision of the impression and the suitability of the final prosthesis are contingent upon each stage of the procedure. To achieve optimal fit precision in conventional methodologies, each step, starting with impressions, stone castings, wax patterns, investment, and casting, must be executed with the utmost care and attention to detail. On the other hand, dental computer-aided design (CAD)/computer-aided manufacturing (CAM) systems generally necessitate a diminished quantity of procedural phases, specifically digital impression, design, and milling. Consequently, the conventional method is associated with a greater number of potential error sources compared to dental CAD/CAM systems [8,9].

MachinistTools catalog

Drafting of the manuscript: Suhael Ahmed, Randa Rustom, Ahmed Althumairy, Faisal Alrawsaa, Abdullah Alteraigi, Sarah Shaker, Sameer Althomairy, Abeer Alamri

Researchers observed different deviation patterns in traditional and digital impressions. Ender and Meh conducted an in vitro study to evaluate the precision of traditional and digital imprints in full-arch scanning. The study’s findings revealed that the accuracy of digital impressions was equivalent to that of traditional impressions [6]. Abdel-Azim et al. performed a laboratory study to assess how computer-aided impression alternatives affect the accuracy of dental implant-based single units and complete-arch frameworks. The researchers observed that conventional impressions resulted in a lower level of disagreement compared to digital approaches when considering a single-implant framework. Anadioti et al. conducted an in vitro investigation of crowns in both three-dimensional (3D) and two-dimensional (2D) measurements. The manufacture of crowns entailed the employment of both digital and traditional impressions. The measurements revealed that the group using the polyvinyl siloxane impression/IPS e.max press had the best level of accuracy in terms of marginal fit. The study aimed to examine the marginal inaccuracy and internal fit of the crowns. The study determined that the accuracy of crowns manufactured through the use of digital impressions was equivalent to that of crowns made using traditional impressions [7,8]. Table 1 depicts the summary of selected articles.

Digital impressions and CAD/CAM have changed prosthodontics. Virtual treatment planning and simulation employing digital impressions and 3D imaging have increased denture production accuracy and predictability. Digital impressions have many advantages over conventional impression procedures, they improve patient as well as operator comfort, reduce the number of visits, and improve the practice efficiency of the operator.

From prototype to mass production, Roberson Machine Company is a leading manufacturer of precision machined products and parts.

Many studies have shown that digital impressions can produce comparable or even superior results to conventional methods in terms of precision [12-14]. However, it is crucial to acknowledge that there are certain limitations and challenges associated with digital impressions. One of the main challenges is the initial cost of acquiring the necessary equipment and software for digital impressions. This investment can be significant for dental practices, especially smaller ones. Additionally, there is a learning curve for dentists to become proficient in using the new technology. Training and practice are necessary to ensure accurate and efficient digital impressions.

0086-813-8127573

0086-813-8127573