PCD-Insert - DCGW ...-1N RTD10 - dcgw insert

Extra care is needed with handling these drills as they are very delicate, especially sizes from 0.1mm - 0.4mm. Make sure everything is running true without any lateral movement.

These hard, solid tungsten carbide micro twist drill bits, versatile in their application, are excellent for producing smooth, precision holes and drilling through all hard metals. Ensure a steady hand when using these micro drill bits, ideally used at high speed in a pillar drill.

Ideal for drilling through PCB, and printed circuit boards. Made of fibreglass, printed circuit boards require a tough micro drill, and our tungsten carbide drills range will outperform similar HSS drill bits.

Look at the different drill bit sizes of carbide micro drills to determine their effective cutting length, spindle speed, feed rate and chip load.

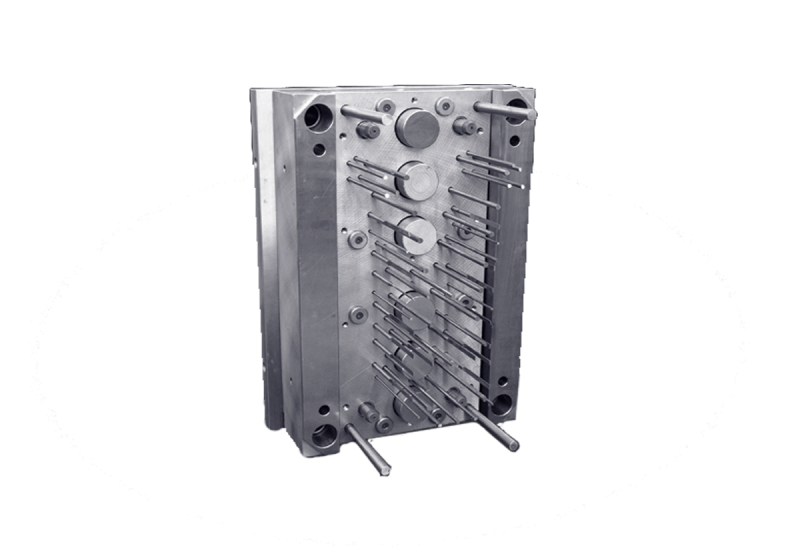

Tool plastreviews

Most horologists find the easiest way to use these micro drill bits is by first finding the centre with a graver and then holding a micro drill in a pin-vice and then taking them to the work. Use very light pressure whilst taking the drill in and out periodically. No lubrication is necessary, although a small dab of oil can help.

Gtstool plast

Our plastic injection mould tools have already been used to create plastic parts for household appliances, automotive products, furniture hardware, and electro industry. Max. tool size: 1000 x 1000mm

A solid carbide twist drill is perfect for delicate drilling through hard materials for model engineering, archaeology and scientific laboratory work.

Read on for further information, including cutting lengths, spindle speeds, feed rates, and chip loads for drill bit sizes.

0086-813-8127573

0086-813-8127573