Penghapusan Logo Mills pada Jersey Timnas ... - mills jersey indonesia

Our machine features differ per model, including multiple headframes, heavy-duty structures, dual in-feed, and out-feed pinch rolls, motorized abrasive belts, air-loaded cylinders, and paper media filtering systems. Contact us today to learn more about our metal deburring machines and how they can help your shop’s bottom line.

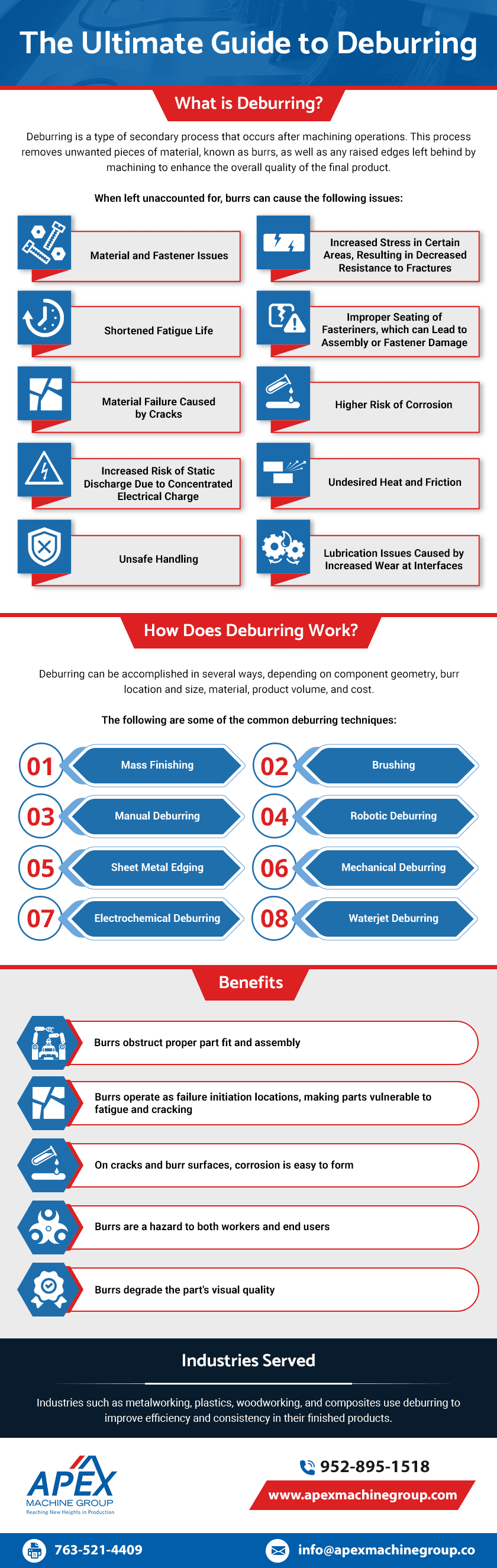

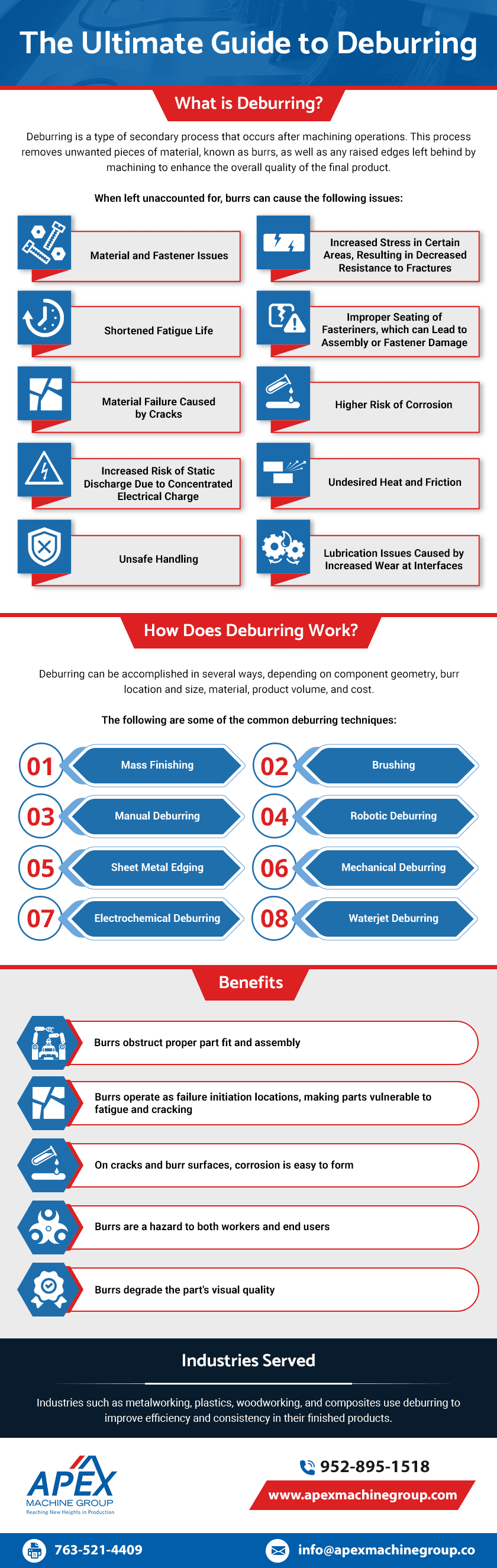

Deburring is a type of secondary process that occurs after machining operations. This process removes unwanted pieces of material, known as burrs, as well as any raised edges left behind by machining to enhance the overall quality of the final product. Machining processes that produce burrs include compressing, piercing, cutting, bending, and shearing.

Deburring machines from Apex Machine Group have a unique design that enables both small and large pieces to run through the same machine. Our equipment features a specialized conveyor belt that firmly holds small parts, a scuffing mechanism that cleans the conveyor belt, and two 4″ dust ports for clearing debris from the belt, making it the ideal solution for shops that need to run components as small as 3″ x 3″.

Various machining processes can produce undesired burrs on workpieces of all kinds. Not only are these imperfections unattractive, but they can also negatively affect the performance and safety of the part or component. In these situations, deburring machines can be used to remove burrs and produce smooth, high-quality parts with optimal functionality. Here, we will discuss deburring, how it works, when it’s used, and how Apex Machine Group can help with your deburring needs.

Deburring is crucial for many applications, as burrs can affect a part’s overall effectiveness, safety, longevity, and functionality. When left unaccounted for, burrs can cause the following issues:

Deburring can be accomplished in several ways, depending on component geometry, burr location and size, material, product volume, and cost. The following are some of the common deburring techniques:

Industries such as metalworking, plastics, woodworking, and composites use deburring to improve efficiency and consistency in their finished products.

Despite the difficulty and expense of the process, deburring is an important element of the manufacturing process for the following reasons:

0086-813-8127573

0086-813-8127573