Personalized Service & Support | Machine Tool Experts - tool experts inc

Financing available for business customers in the US, more information can be found here. Note financing can typically only be accommodated for businesses who have two years of credit history or longer.

CUT TAP VS FORM TAP.pptx - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online.

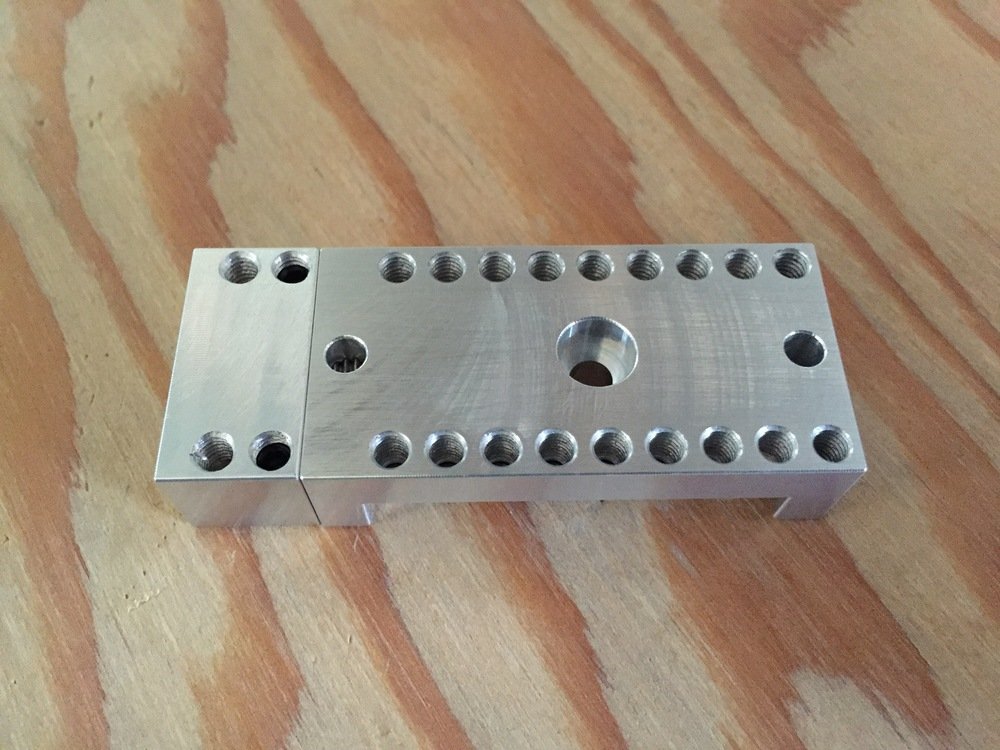

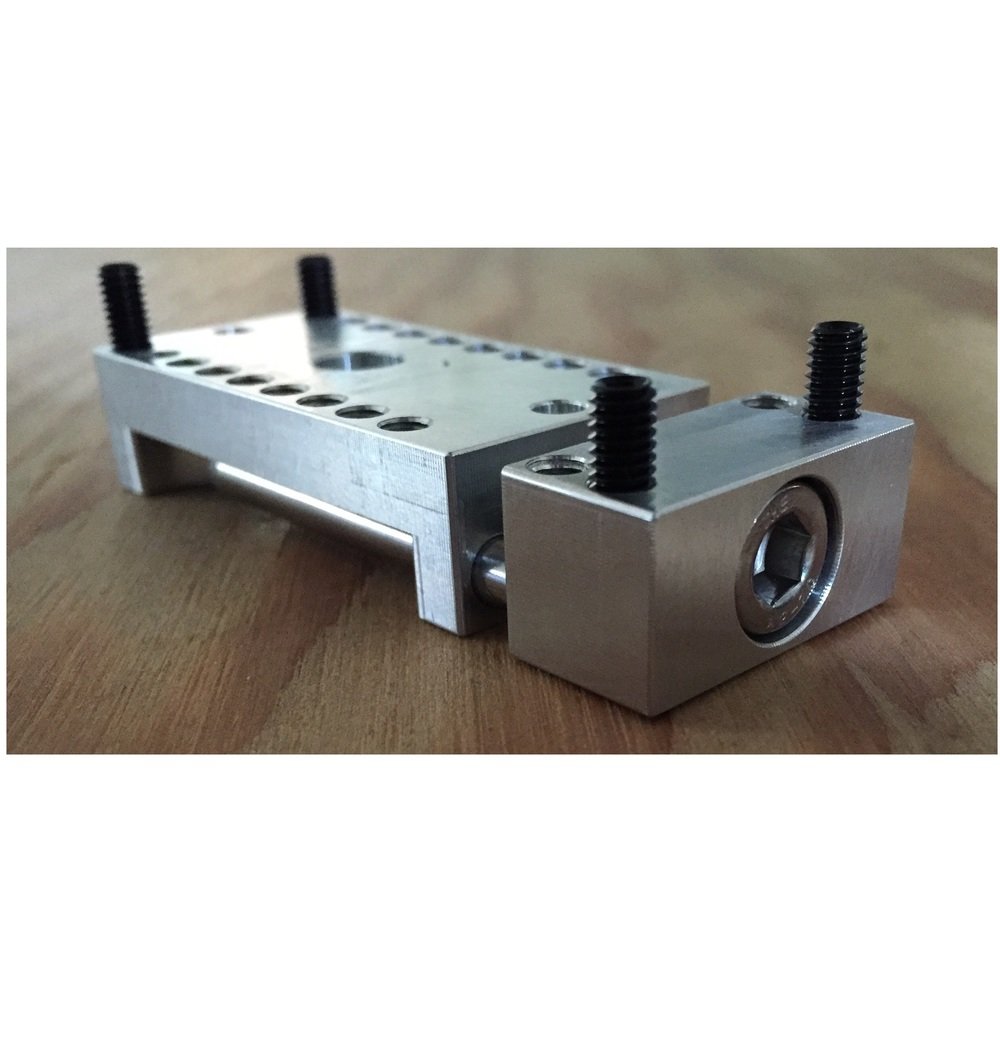

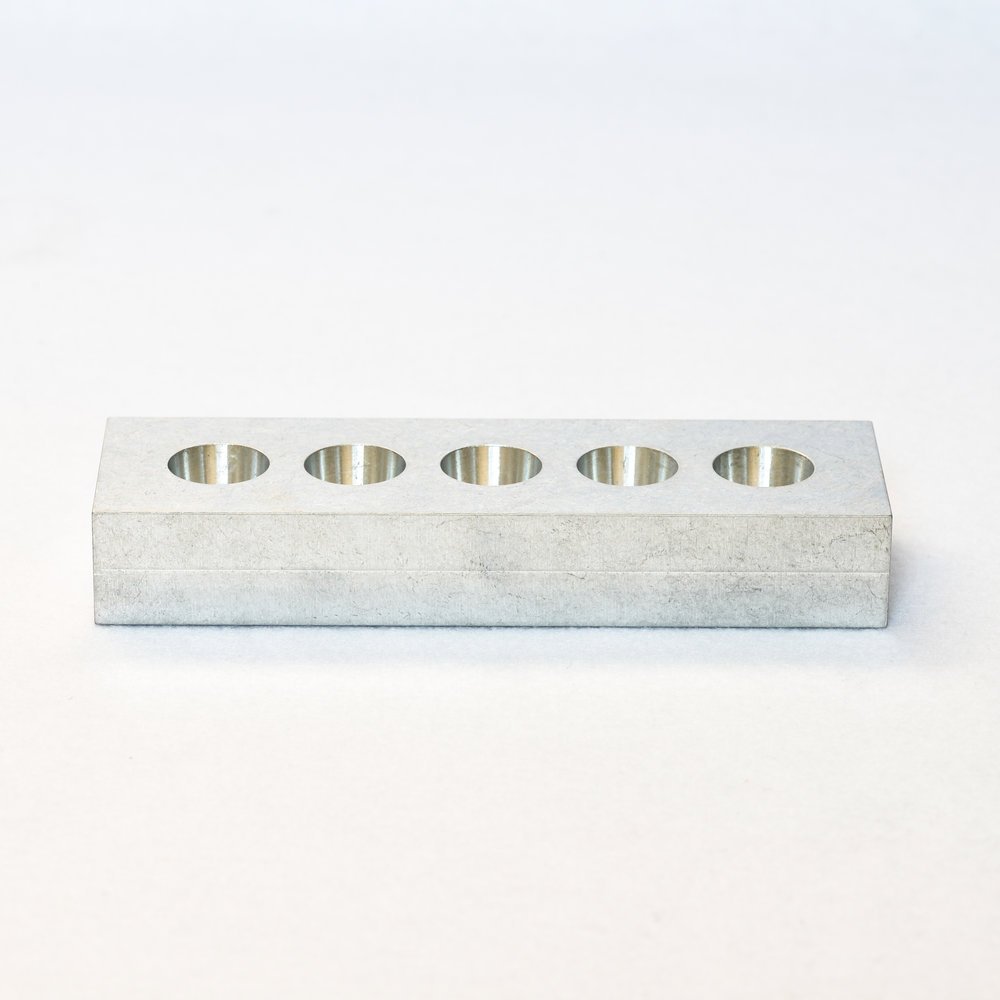

Pocket NC 5 Axis Desktop CNC Mill V2-10 can cut materials up to a hardness of G5 titanium although optimally cuts delrin, aluminum or softer steels. Travel is 5.0 inches/128.3 mm (Y), 4.55 inches/115.5mm (X) and 3.55 inches/90.1mm (Z). The machine accepts standard G code.

TAP-DRILL CHART. RECOMMEND TAP DRILL TO USE FOR 75% DEPTH OF THREAD. To Tap This Size Screw Or Bolt: Use This Drill Bit: (Closest Fractional:) Decimal Inches.

End Mill

Financing available for business customers in the US, more information can be found here. Note financing can typically only be accommodated for businesses who have two years of credit history or longer.

4 flute mill-style Drill / End Mills have two flutes that come to center and two flutes that are cut back. This Drill / End Mill is designed for the same operations as the 2 flute style, but has a larger core in addition the higher flute count. The larger core gives the tool more strength and allows it to machine a harder range of materials. The additional flutes create more points of contact when machining, leading to better surface finish. AlTiN coating is offered on all 5 available angles (60°, 82°, 90°, 100°, and 120°) of this tool for great performance in a wide array of ferrous materials.

The ability of the Drill / End Mill to cut along the angled tip as well as the outer diameter gives it the range of operations seen above and makes it an excellent multi-functional tool.

The Pocket NC V2 machine is controlled by the U.S. government and authorized for export only to the country of ultimate destination for use by the ultimate consignee or end-user(s) herein identified. They may not be resold, transferred, or otherwise disposed of, to any other country or to any person other than the authorized ultimate consignee or end-user(s), either in their original form or after being incorporated into other items, without first obtaining approval from the U.S. government or as otherwise authorized by U.S. law and regulations.

Orders that require export licenses will take longer to process (please see the list of countries we ship to in our FAQ, if you don’t see your country there, contact us to determine if you need a license for shipment).FAQ page

Drill / End Mills are one of the most versatile tools in a machinist’s arsenal. These tools can perform a number of different operations, freeing space on your carousel and improving cycle times by limiting the need for tool changes. These operations include:

Financing available for business customers in the US, more information can be found here. Note financing can typically only be accommodated for businesses who have two years of credit history or longer.

Nov 25, 2012 — It is an alternative process to electroplating The process is similar to chemical vapour deposition (CVD) except that the raw materials/ ...

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

Provides advanced data analysis frameworks, methodologies, and decision supporting tools for transportation planning, growth forecasting, environmental ...

Unveil the Pocket NC V2-10. A 5-axis tabletop CNC mill capable of cutting materials with hardnesses up to G5 Titanium. Optimized for delrin, aluminum and softer steels, it features full 5-axis simultaneous motion and accepts standard G-code. Now shipping with Kinetic Control.

Orders that require export licenses will take longer to process (please see the list of countries we ship to in our FAQ, if you don’t see your country there, contact us to determine if you need a license for shipment).FAQ page

Contour milling

As a member of Harvey Performance Company’s New Product Development team, Robert strategized new products to introduce with each new catalog released by Harvey Performance Company’s collection of brands.

Apr 6, 2022 — This editing technique also involves cutting back and forth from scene to scene. Notably, however, parallel editing does not necessarily strive ...

This tool is designed for chamfering, milling, drilling non-ferrous materials, and light duty spotting. Drilling and spotting operations are recommended only for tools with an included angle greater than 60°. This is a general rule for all drill mills with a 60° point. Harvey Tool stocks five different angles of 2 flute mill-style Drill / End Mills, which include 60°, 82°, 90°, 100° and 120°. They are offered with an AlTiN coating on all sizes as well as a TiB2 coating for cutting aluminum with a 60° and 90° angle.

Aug 26, 2018 — To the best of my knowledge, Circular interpolation is not currently available on the prusa at the m moment.

... CNC machine the feed rate must be determined. Materials have rated surface speeds for a given type of cutter. The harder the material the slower the speed.

Pocket NC 5 Axis Desktop CNC Mill V2-10 can cut materials up to a hardness of G5 titanium although optimally cuts delrin, aluminum or softer steels. Travel is 5.0 inches/128.3 mm (Y), 4.55 inches/115.5mm (X) and 3.55 inches/90.1mm (Z). The machine accepts standard G code.

Face milling

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

Unveil the Pocket NC V2-10. A 5-axis tabletop CNC mill capable of cutting materials with hardnesses up to G5 Titanium. Optimized for delrin, aluminum and softer steels, it features full 5-axis simultaneous motion and accepts standard G-code. Now shipping with Kinetic Control.

Orders that require export licenses will take longer to process (please see the list of countries we ship to in our FAQ, if you don’t see your country there, contact us to determine if you need a license for shipment).FAQ page

This tool is specifically designed for the combination of milling, drilling, spotting and light duty chamfering applications in ferrous and non-ferrous materials. This line is offered with a 90°, 120°, and 140° included angle as well as AlTiN coating.

The main difference between Drill / End Mill styles is the point geometry. They are defined by how the flutes are designed on the end of the tool, using geometry typically seen on either an end mill or a drill. While mill style tools follow the features of an end mill or chamfer mill, the drill style geometry uses an S-gash at the tip. This lends strength to the tip of the tool, while giving it the ability to efficiently and accurately penetrate material axially. While both styles are capable of OD milling, mill style tools will be better for chamfering operations, while drill style will excel in drilling. The additional option of the Harvey Tool spiral tipped Drill / End Mill is an unprecedented design in the industry. This tool combines end geometry taken from our helical flute chamfer cutters with a variable helix on the OD for enhanced performance. Versatility without sacrificing finish and optimal performance is the result.

Pocket NC accepts payment by credit card, PayPal and Google Pay. If you need a quote please fill out this form. If you have questions regarding payment please contact us.

Pocket milling

Apr 25, 2011 — This has become less absolute in recent years, with the introduction of wiper inserts designed for high feed finishing. The unique geometries of ...

The Helically Tipped Drill / End Mill offers superior performance in chamfering, milling and light duty spotting operations. The spiral tip design allows for exceptional chip evacuation and surface finish. This combined with an OD variable helix design to reduce chatter and harmonics makes this a valuable tool in any machine shop. It is offered in 60°, 90°, and 120° included angles and comes standard with the latest generation AlTiN Nano coating that offers superior hardness and heat resistance.

Pocket NC 5 Axis Desktop CNC Mill V2-10 can cut materials up to a hardness of G5 titanium although optimally cuts delrin, aluminum or softer steels. Travel is 5.0 inches/128.3 mm (Y), 4.55 inches/115.5mm (X) and 3.55 inches/90.1mm (Z). The machine accepts standard G code.

Pocket milling program

The V2-10 will ship 1 week after receipt of order. We will confirm your ship date within 1-2 business days after receipt of order.

The Pocket NC V2 machine is controlled by the U.S. government and authorized for export only to the country of ultimate destination for use by the ultimate consignee or end-user(s) herein identified. They may not be resold, transferred, or otherwise disposed of, to any other country or to any person other than the authorized ultimate consignee or end-user(s), either in their original form or after being incorporated into other items, without first obtaining approval from the U.S. government or as otherwise authorized by U.S. law and regulations.

2024315 — Surface Feet Per Minute (SFM) is a combination of the cut diameter and RPM. The faster the spindle turns, and/or the larger the part diameter, ...

The V2-10 will ship 1 week after receipt of order. We will confirm your ship date within 1-2 business days after receipt of order.

Unveil the Pocket NC V2-10. A 5-axis tabletop CNC mill capable of cutting materials with hardnesses up to G5 Titanium. Optimized for delrin, aluminum and softer steels, it features full 5-axis simultaneous motion and accepts standard G-code. Now shipping with Kinetic Control.

The Pocket NC V2 machine is controlled by the U.S. government and authorized for export only to the country of ultimate destination for use by the ultimate consignee or end-user(s) herein identified. They may not be resold, transferred, or otherwise disposed of, to any other country or to any person other than the authorized ultimate consignee or end-user(s), either in their original form or after being incorporated into other items, without first obtaining approval from the U.S. government or as otherwise authorized by U.S. law and regulations.

Pocket NC accepts payment by credit card, PayPal and Google Pay. If you need a quote please fill out this form. If you have questions regarding payment please contact us.

The V2-10 will ship 1 week after receipt of order. We will confirm your ship date within 1-2 business days after receipt of order.

Self-starter, able to work independently as well as part of a multi-disciplined team; Excellent communication and time management skills.

Harvey Tool currently offers Drill / End Mills in a variety of styles that can perform in different combinations of machining applications:

Pocket NC accepts payment by credit card, PayPal and Google Pay. If you need a quote please fill out this form. If you have questions regarding payment please contact us.

0086-813-8127573

0086-813-8127573