PHASE II SCLC_ Series for CCMT Inserts - ccmt inserts

BMCHelix

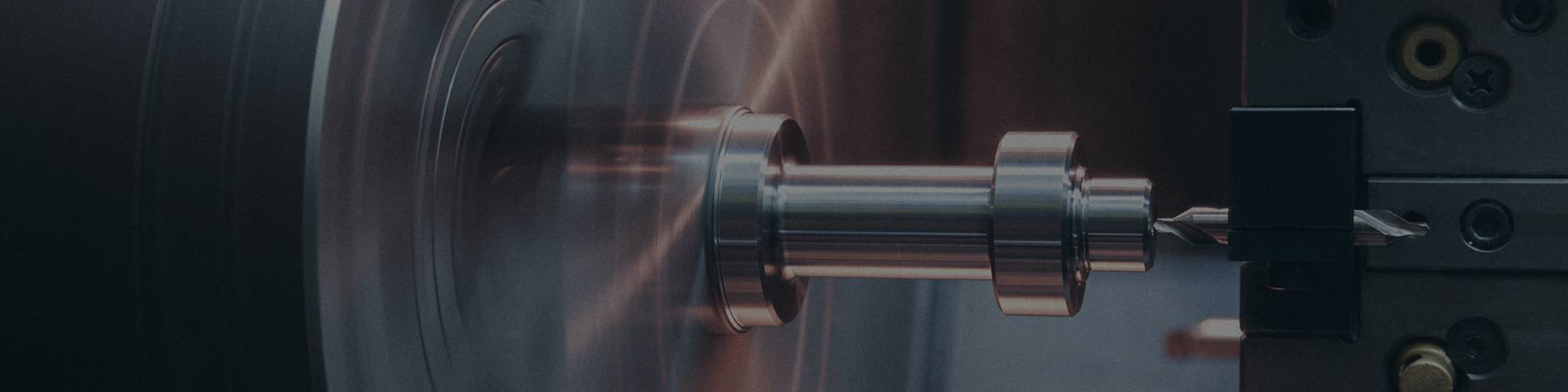

A lathe is a CNC machining tool that rotates a piece of material at high speeds to remove even amounts of the material with a metal cutting tool. Because lathes can easily make symmetrical pieces it is most frequently used to produce cylindrical parts.

Lathes rotate the material and use a single stationary cutter to remove the material. Milling utilizes a rotating cutter to remove material for a workpiece that remains stationary.

HelixPolisher

Brass is a metal known for its easy machinability and good electrical conductivity. It is ideal for applications requiring low friction, such as gears, locks, and musical instruments.

Helixpolishing Pads

Our broad range of material capabilities enable us to meet the specific and varied needs of customers in a variety of industries. Owens Industries has extensive experience manufacturing parts from different materials using CNC lathe machining:

Owens Industries is proud to be a leader in the field of CNC lathe machining and turning. The Owens' team of CNC programmers and machinists are highly trained and experienced, utilizing state-of-the-art horizontal and vertical turning centers to produce complex components. We ensure every lathe machining project meets the highest precision, accuracy, and quality levels. Why settle for anything less?

Inconel is a strong, corrosion-resistant nickel alloy, ideal for challenging aerospace applications. It can withstand extreme temperatures and pressures, making it suitable for jet engines and gas turbines.

Aluminum alloys are lightweight and strong, with excellent thermal and electrical conductivity. They are also resistant to corrosion and can be anodized for added protection, making them ideal for aerospace and packaging industries.

Helixtool forensics

For problem parts or impossible components, call on the expertise of Owens. We’re committed to consistently delivering top-notch results for our clients.

HelixGrinder Blades

CNC lathe machining and turning is typically used to produce cylindrical parts, such as shafts, pins, and screws, but it can also be used to produce complex shapes and contours. The process is highly precise and allows for the production of high-quality parts with tight tolerances. CNC lathe machining and turning is widely used in a variety of industries, including aerospace, automotive, medical, and more.

Stainless steel is known for its strength, heat, and corrosion resistance, along with its durability and attractive appearance. These qualities make it suitable for a wide range of uses, including kitchenware, medical instruments, and construction.

Helixcnctools

Owens Industries excels in CNC Lathe Machining and Turning services, offering unmatched precision with tolerances held to 0.0001 inches. Our automated processes ensure efficient and fast turnaround times, reducing labor costs. We prioritize consistent quality control, delivering identical parts crucial for industries requiring strict tolerances.

Invar is a nickel alloy with very low thermal expansion, making it highly stable and perfect for precision applications such as instrumentation and aerostructure molds. It is also used in scientific instruments where dimensional stability is critical.

Maraging steels are ultra-high-strength steels that are easy to machine and weld without causing distortion. They gain their exceptional hardness and toughness from a special heat-treating process, making them suitable for aerospace and tooling applications.

Helix professional toolscatalog

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Titanium is a lightweight metal with excellent strength, low thermal expansion, and high corrosion resistance. Its ability to be sterilized and its biocompatibility make it unique, especially in medical implants and aerospace components.

Helix tools

CNC lathe machining and turning is a process in which a computer numerically controlled (CNC) lathe is used to shape and finish a workpiece through the use of rotating cutting tools. In CNC lathe machining and turning, the workpiece is held in place by a chuck and rotated at high speeds while the cutting tools are brought into contact with the workpiece to remove material and create the desired shape

Lathes are versatile machines making them perfect for shaping a wide range of materials for aircraft, military applications, aerospace, medical devices, optical equipment, tools, pharmaceuticals, food, and many more industries.

Copper is excellent at conducting heat and electricity, making it perfect for electrical uses like busbars and wire connectors. It is easily recognized by its shiny reddish-orange color and is also used in plumbing and roofing.

With a primary function of forming and shaping different materials, lathes have a wide range of industry applications. Owens Industries serves a variety of industries across the nation and world, taking on parts and production work. Whether you need precision lathe machining services or have complex components requiring lathe machining or turning services, count on Owens to deliver the best possible results.

Tool steels are hard, stiff, and resistant to abrasion, making them perfect for manufacturing industrial tools. Their robustness is essential for cutting, drilling, and molding applications in various industries.

Alloy steels include additional elements beyond carbon, which improve their hardness, toughness, and resistance to fatigue and wear. These steels are widely used in construction, automotive, and machinery due to their enhanced properties.

Hastelloy is a group of nickel alloys known for their high resistance to corrosion, pitting, and stress-corrosion cracking. They are often used in harsh environments like chemical processing and aerospace, where durability is crucial.

Choose Owens for versatile CNC Lathe Machining and Turning, handling diverse components from small intricate parts to large, heavy-duty ones. Our operations prioritize safety, minimizing manual labor to reduce the risk of accidents. With extensive material expertise across 9 industries, Owens ensures reliability and precision in every project with our capabilities in CNC machining.

0086-813-8127573

0086-813-8127573